Catalyst formulation for methanol conversion catalysts

A technology of catalysts and catalyst particles, applied in the direction of catalyst activation/preparation, carbon compound catalysts, catalysts, etc., which can solve the problems of reducing the production capacity of conversion reactors and increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

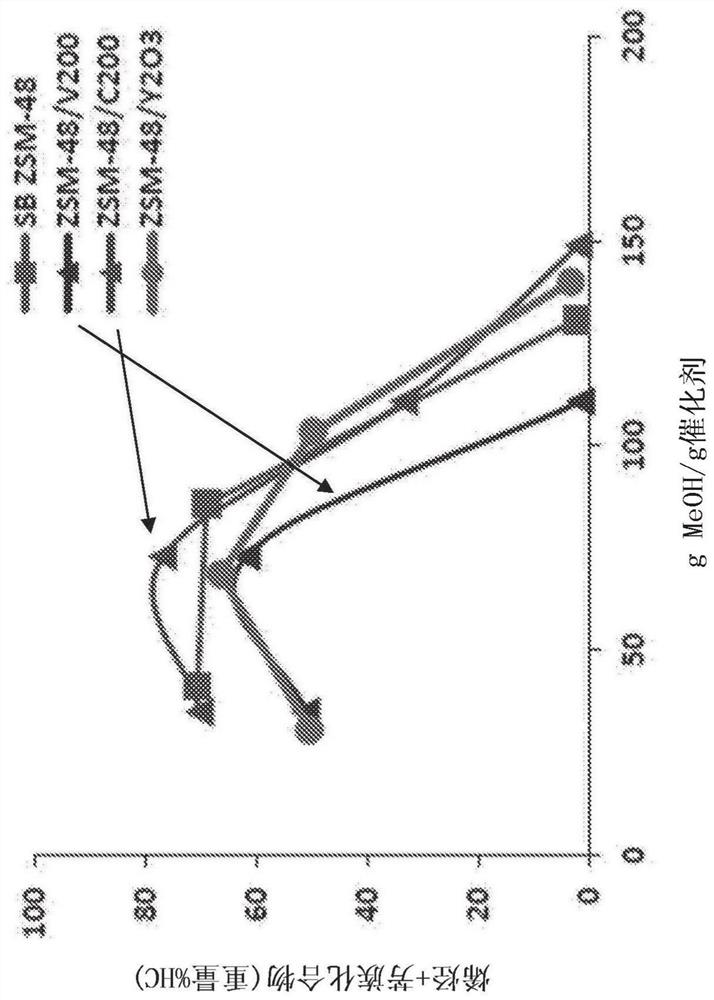

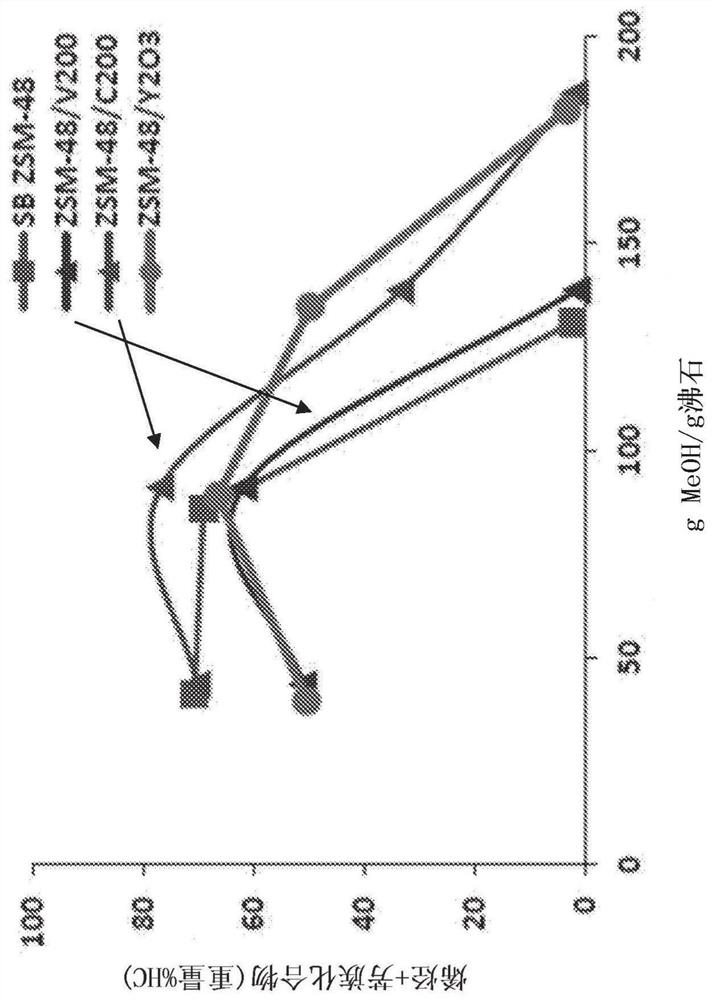

[0041] Example 1 - Addition of weak base during catalyst formulation: ZSM-48

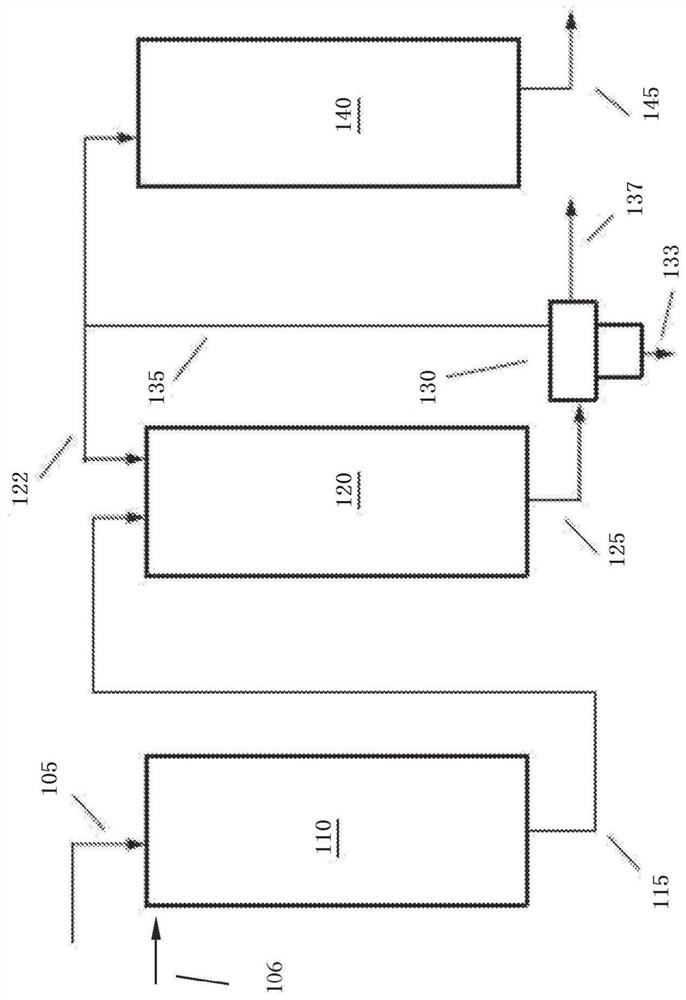

[0042] In Example 1, various catalysts were tested in an isothermal fixed bed reactor where no recirculation was performed, but recirculation is possible and may be desirable as it can further extend the catalyst cycle time. This reactor configuration is illustrative and should not be considered limiting. In this example, pure methanol was used as the model feed, but co-feeds such as water, oxygenates, olefins, paraffins and aromatics are feasible and may even be desirable. For catalysts based on ZSM-48, test conditions included zeolite-based 2h -1 Weight Hourly Space Velocity (WHSV). In other words, the weight of the methanol feed is selected based on the weight of the zeolite in the catalyst rather than the total weight of the catalyst. Other conditions included a temperature of 450°C and a pressure of about 100 kPa-g. For catalysts based on ZSM-5, the conditions tested were WHSV (based on z...

Embodiment 2

[0049] Example 2 - Addition of weak base during catalyst formulation: ZSM-5

[0050] Additional characterization of the effect of adding a weak base (TEAOH) during catalyst formulation was done by using a binder comprising 65% by weight ZSM-5 and 35% by weight Catapal-200 alumina (specific surface area less than 100 m 2 / g) catalyst. The test conditions (as described above in Example 1) are believed to be representative of suitable conditions for the conversion of methanol to gasoline. Catalyst contact life was determined based on the time required for the concentration of unconverted methanol in the aqueous phase to reach 1%. Under the first test conditions, the catalyst formulated without the addition of TEAOH had a contact life of 4.8 days. Under the second test conditions, a catalyst formulated by adding 3.0 wt% of a weak base to alumina yielded a contact life of 5.1 days. Under the third test condition, the catalyst formulated by adding 3.0 wt% TEAOH to the combined ...

Embodiment approach 1

[0056] Embodiment 1. A process for converting an oxygenate feed using an oxygenate conversion catalyst comprising: an average reaction temperature of 230°C to 550°C, total pressure and 0.1hr -1 to 10.0hr -1 At a WHSV of , an oxygenate-containing feed is contacted with an oxygenate conversion catalyst comprising a zeolite and 1% by weight to 90% by weight of a binder to form a converted effluent with 250m 2 / g or less specific surface area, wherein the oxygenate conversion catalyst comprises a catalyst formulated during formulation using 1.5% to 5.0% by weight of a weak base in a mixture of zeolite and binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com