Preparation method of GO/MoS2 quantum dot layered two-dimensional film

A quantum dot layer, quantum dot technology, applied in the field of membrane separation, can solve the problems of destroying GO, lattice spacing reducing membrane retention rate and stability, etc., achieving good stability and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

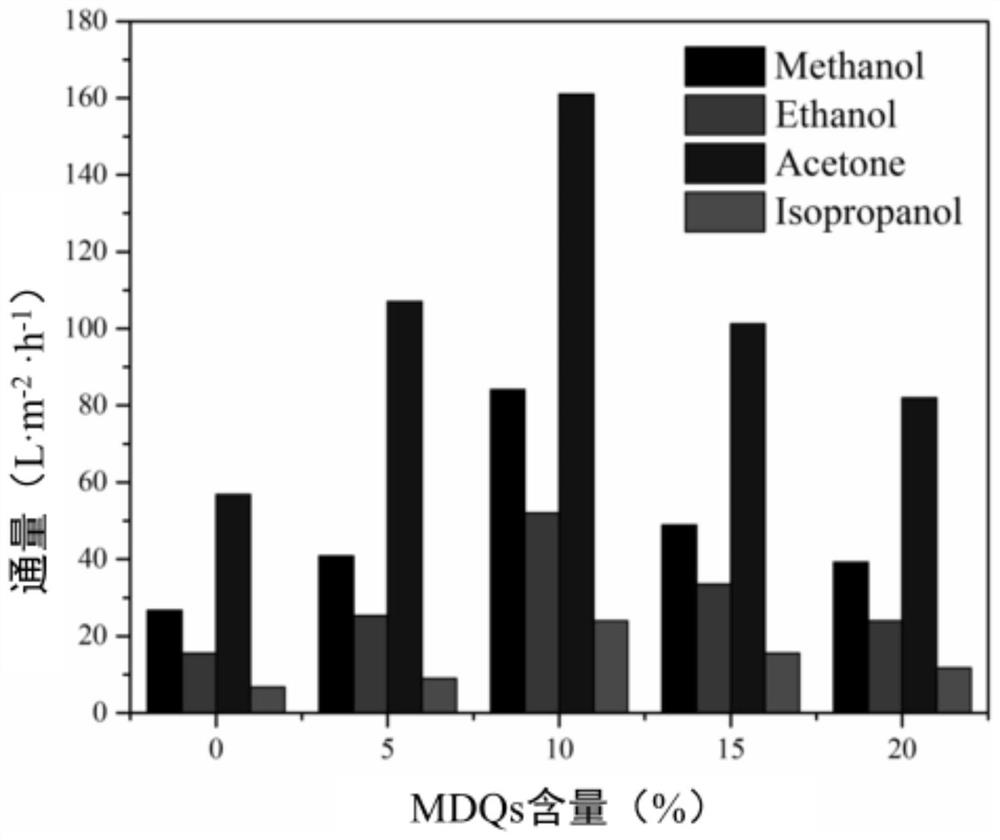

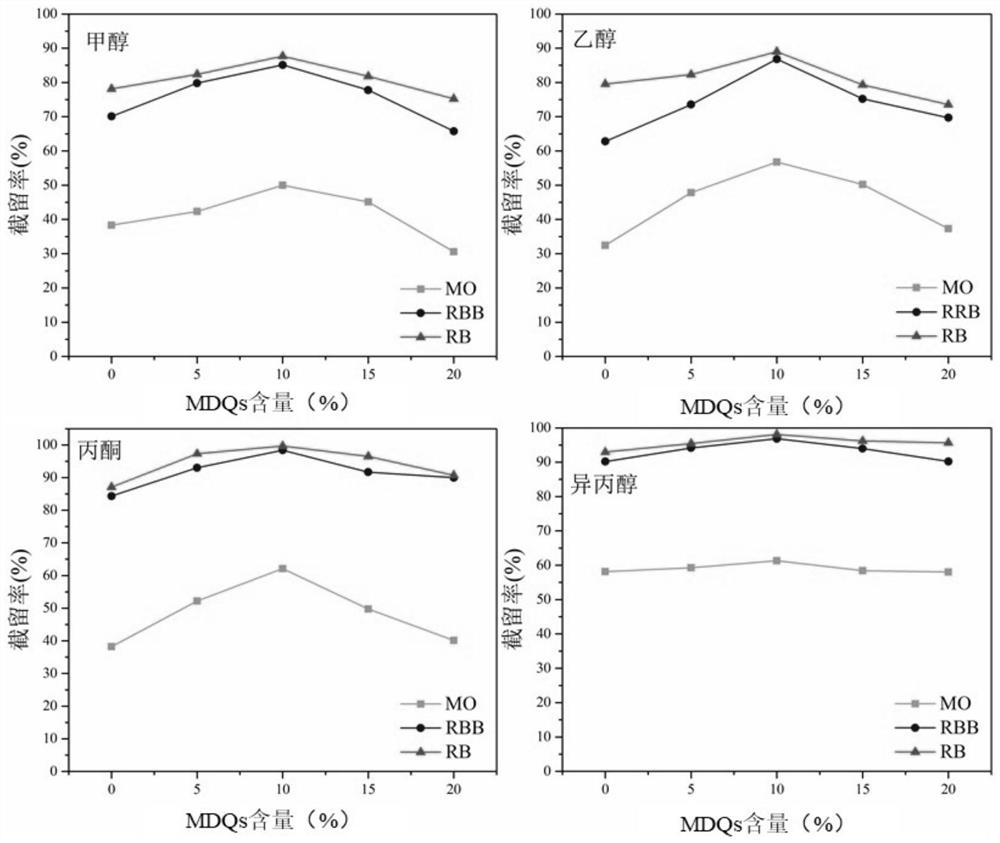

Embodiment 1

[0034] In Example 1, molybdenum disulfide MoS in the mixture solution 2 The mass ratio of quantum dots was 5%.

[0035] (1) Preparation of 0.01mg / ml molybdenum disulfide MoS 2 Quantum dot solution and 0.1 mg / ml graphene oxide GO solution.

[0036] (2) Add 3ml diluted molybdenum disulfide MoS to 250ml deionized water 2 The quantum dot solution and 5.7ml graphene oxide GO solution were ultrasonicated for 30 minutes to form a homogeneous mixture solution. Molybdenum disulfide MoS in the mixture solution 2 The mass ratio of quantum dots was 5%.

[0037] (3) The above mixture solution was vacuum filtered through a porous nylon base membrane with a pore size of 0.22 μm, and dried overnight at ambient temperature.

[0038] (4) Obtain molybdenum disulfide MoS 2 A layered two-dimensional film with a mass ratio of 5% quantum dots is labeled as GM-5.

Embodiment 2

[0040] The experimental operation steps and conditions are the same as in Example 1, except that the molybdenum disulfide MoS in the mixture solution 2 The mass ratio of quantum dots is 10%, that is, in step (2), the added molybdenum disulfide MoS 2 The quantum dot solution volume is 6ml, and the added graphene oxide GO solution volume is 5.4ml. Molybdenum disulfide MoS 2 The quantum dot solution is a 10% layered two-dimensional film, marked as GM-10.

Embodiment 3

[0042] The experimental operation steps and conditions are the same as in Example 1, except that the molybdenum disulfide MoS in the mixed solution is 2 The mass ratio of quantum dots is 15%, that is, in step (2), the added molybdenum disulfide MoS2 The amount of quantum dot solution is 9ml, and the amount of graphene oxide GO solution added is 5.1ml. Molybdenum disulfide MoS 2 A layered two-dimensional film with a mass ratio of quantum dots of 15% is labeled as GM-15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com