Cooling system of coiling block of coiling machine

A technology of cooling system and coiling machine, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve problems such as coil chilling, affecting product quality, and temperature rise, so as to improve use efficiency and product quality , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

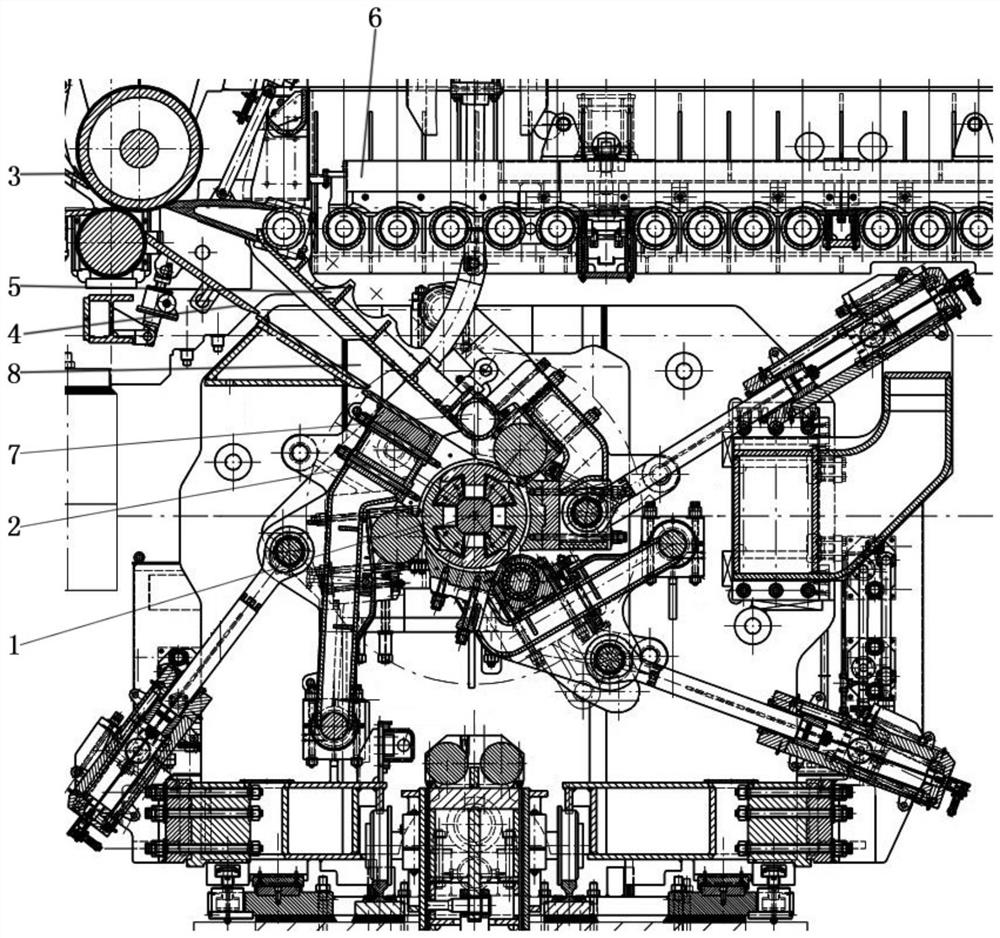

[0022] Combine below Figure 1 to Figure 6 The present invention will be described.

[0023] Such as figure 1 The coiler shown includes a reel 1, a roll-assisting mechanism 2, a pinch roller 3, a fixed slide 4, and a movable slide 5. The roll-assisting mechanism 2 is arranged around the reel 1. One or four, the rolling aid mechanism 2 in the present embodiment is three, with the drum 1 as the axis, the three rolling aid mechanisms 2 are evenly arranged around the drum 1, the pinch roller 3 and the fixed slide plate 4 One end of the movable slide plate 5 is hinged on the strip conveying device 6 , and the other end of the movable slide plate 5 is a free end and is provided with a guide roller 7 .

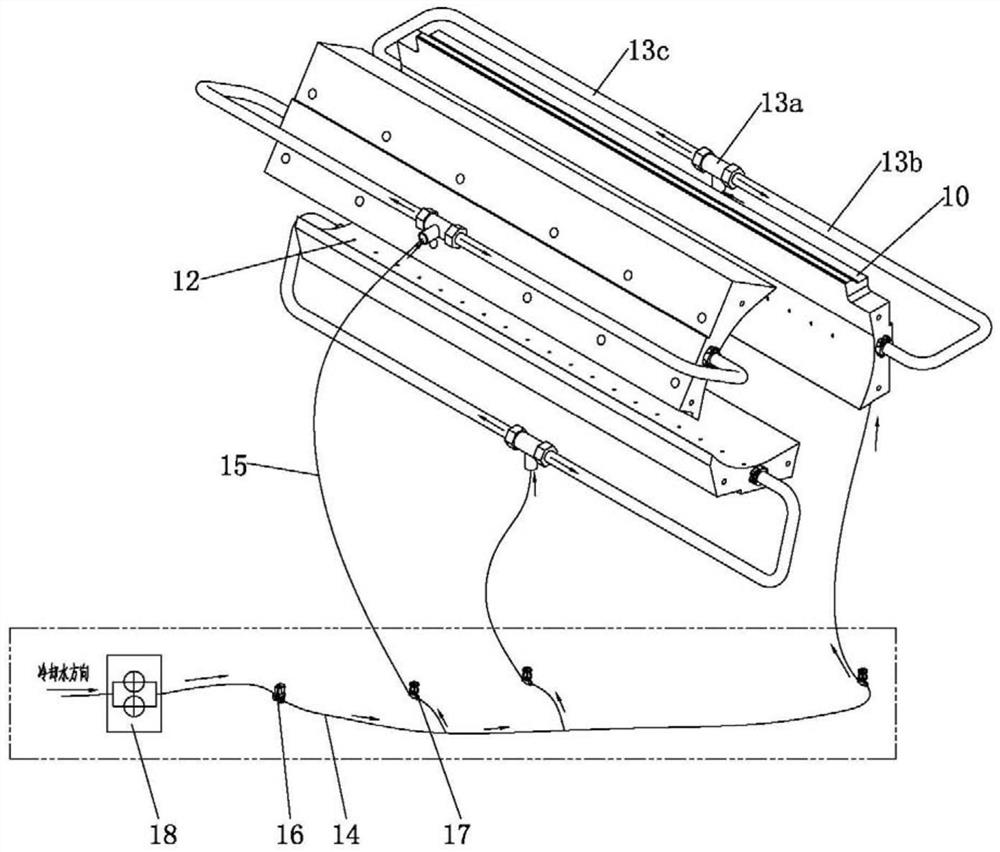

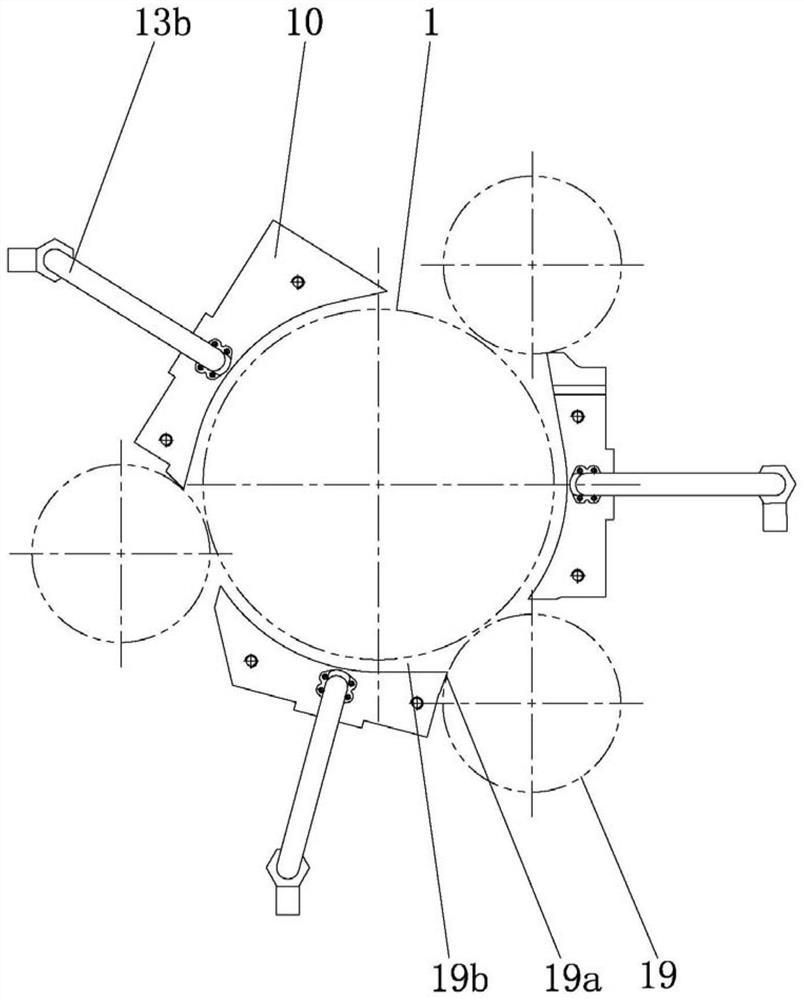

[0024] The present invention improves the coiler of the above-mentioned structure, and the specific improvement is to add a cooling system for the reel 1 to be rolled, such as figure 2 As shown, the cooling system of the reel of the coiler in this embodiment includes a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com