Anti-corrosion natural gas pipeline laying and welding auxiliary device

A technology for natural gas pipelines and auxiliary devices, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of reduced welding efficiency, difficult calibration of workers, and difficult accurate connection of pipelines, etc., to achieve good stability and improve accuracy performance, ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

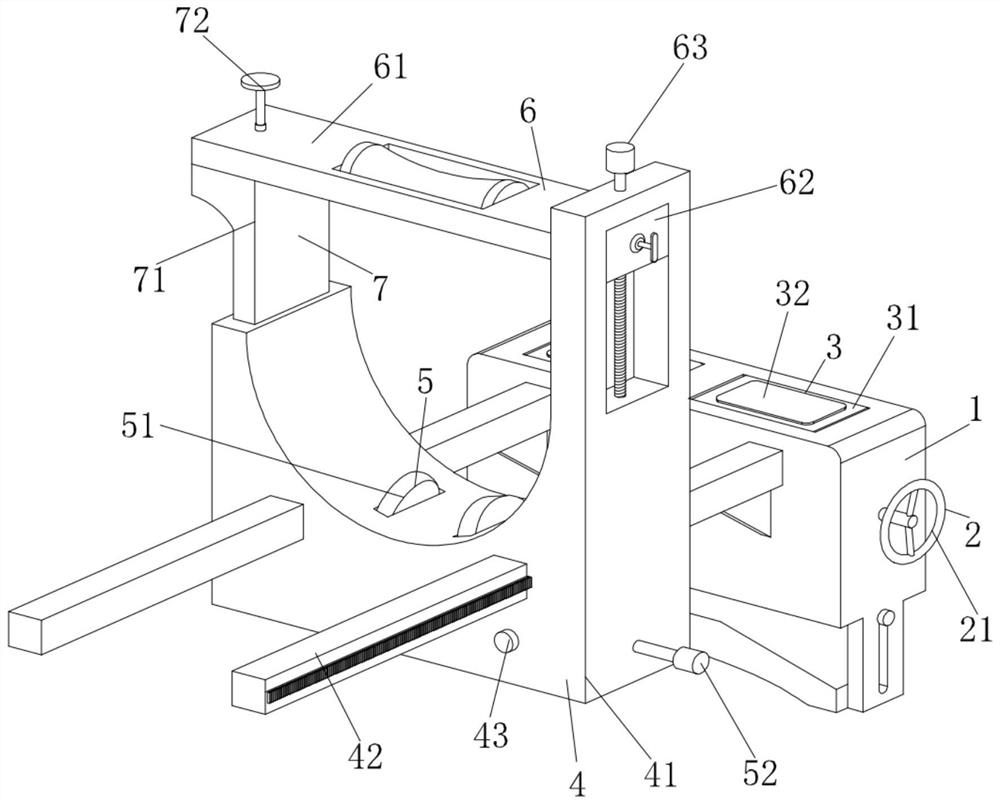

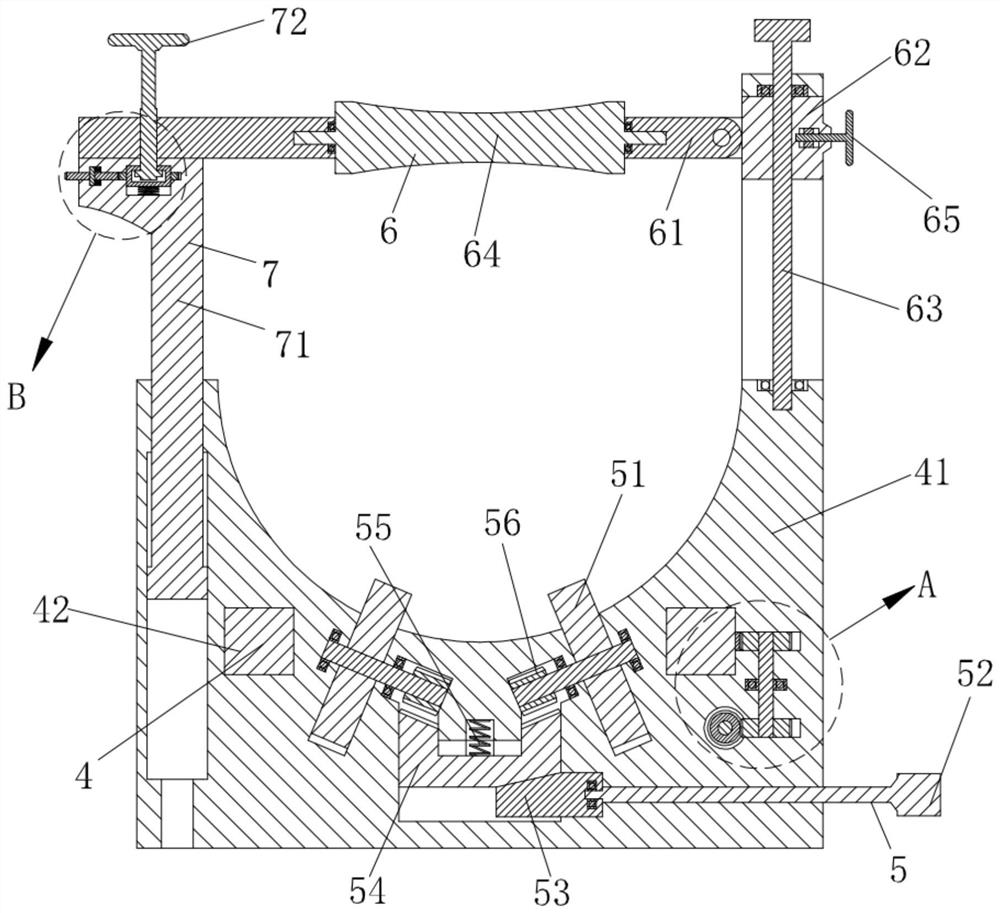

[0027] like Figure 1-Figure 8 As shown in the figure, an auxiliary device for anti-corrosion natural gas pipeline laying and welding according to the present invention includes a support base 1, and a lift structure 2 is arranged inside the support base 1; a limit structure is arranged between the lift structure 2 and the support base 1 3; the side of the support base 1 is connected with a guide structure 4; the bottom side of the guide structure 4 is provided with a moving structure 5; the top side of the guide structure 4 is provided with a clamping structure 6; the clamping structure 6 A connecting structure 7 is connected with the guiding structure 4 .

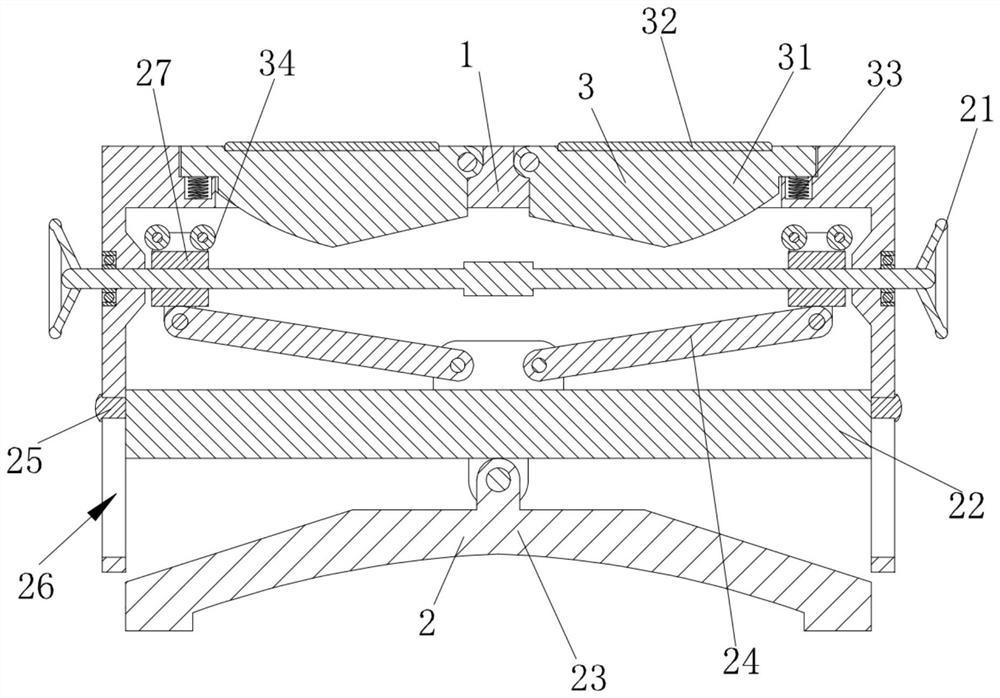

[0028] Specifically, the lifting structure 2 includes a first screw 21 , a first sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com