Engineering machinery vehicle part welding tool and welding process

A technology for vehicle parts and welding tooling, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex connection relationship and difficult welding operation, and achieve improved welding accuracy, easy welding fixation, and easy welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

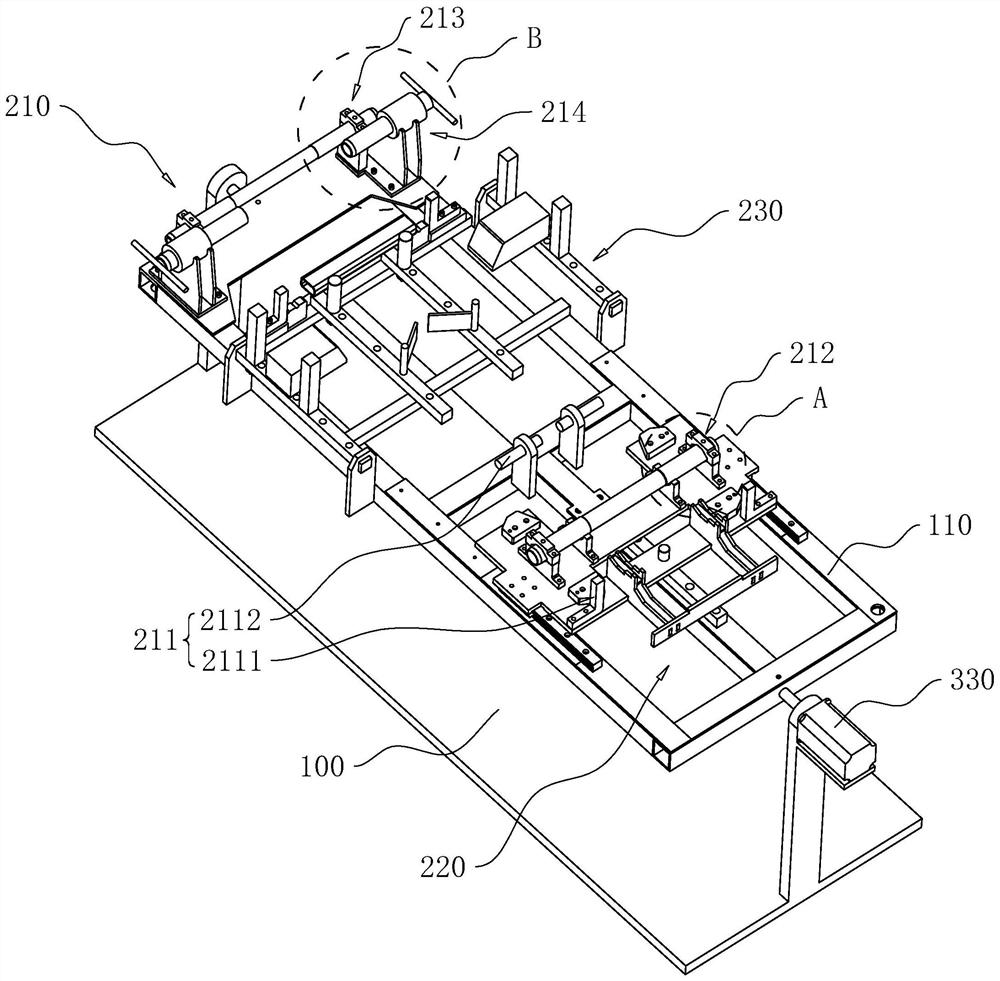

[0051] refer to image 3 , the construction machinery vehicle component welding tool includes an underframe 100 fixedly placed on the ground, and the underframe 100 is rotatably connected with a support frame 110 . A driving motor 330 is also fixedly disposed on the bottom frame 100 , and the output shaft of the driving motor 330 is arranged horizontally and fixedly connected with the supporting frame 110 . The connection point between the support frame 110 and the drive motor 330 is located at the midpoint of the support frame 110 in the width direction.

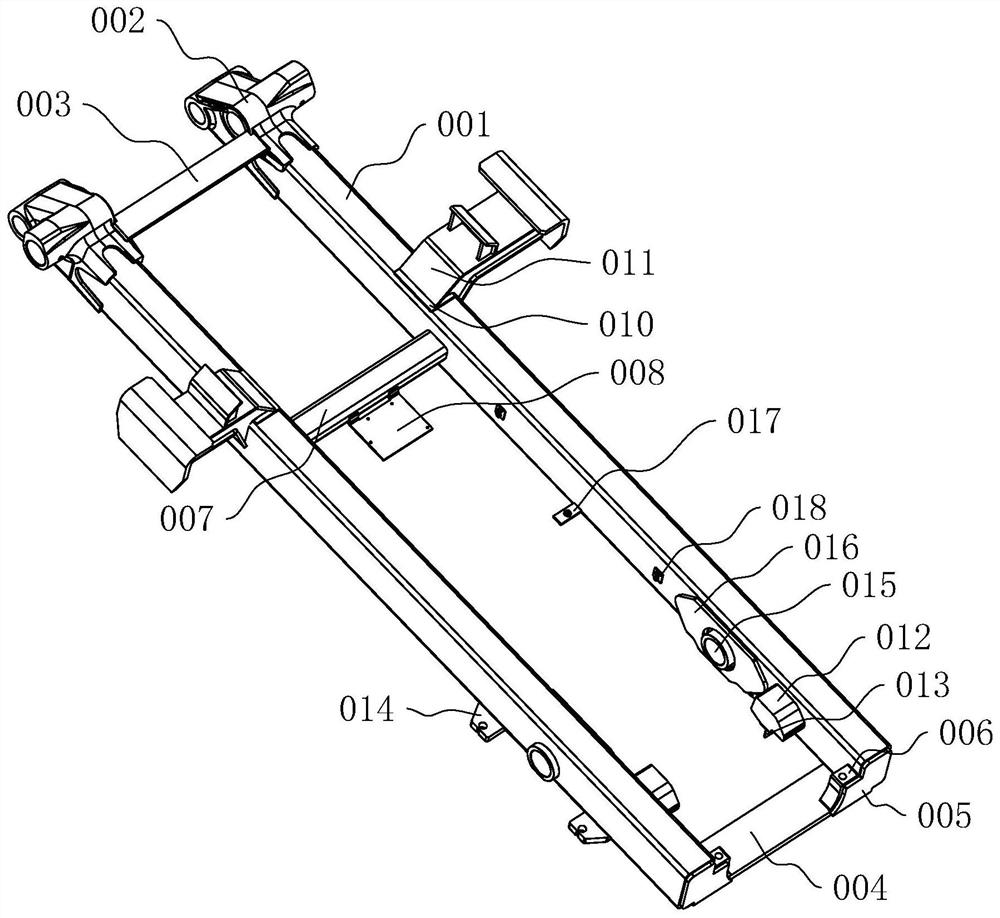

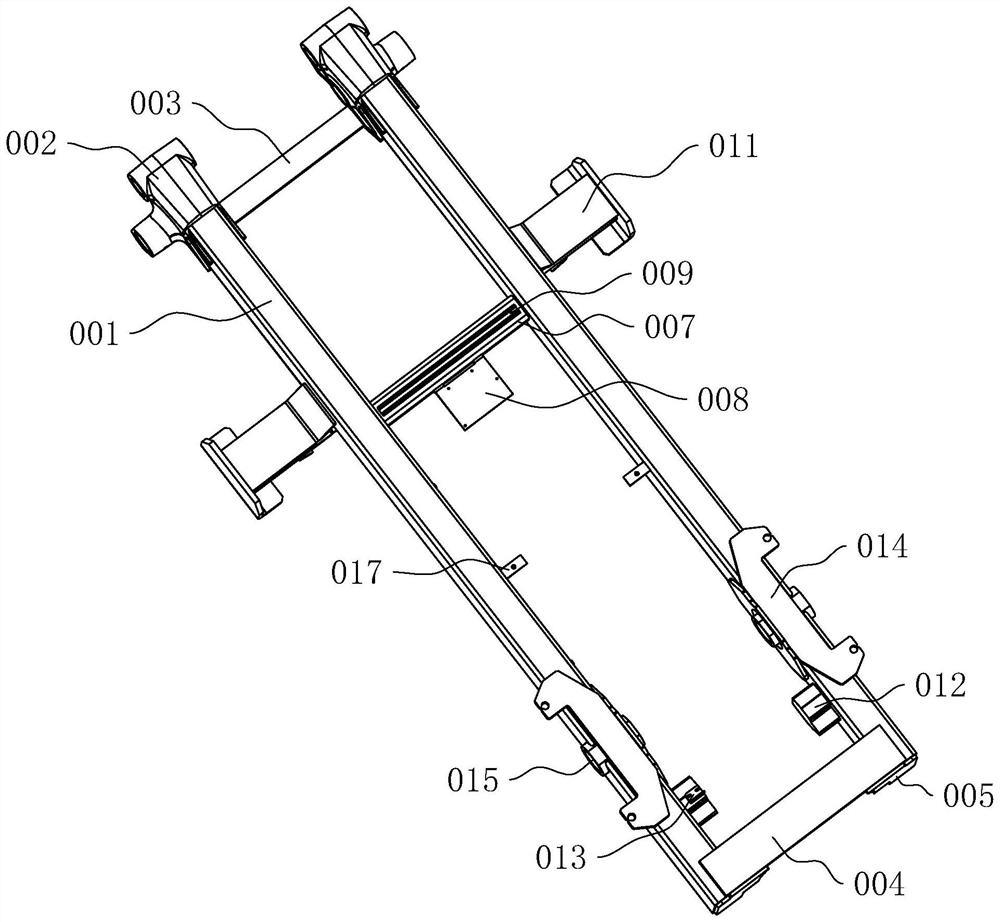

[0052] refer to figure 1 and image 3 , the support frame 110 is provided with a clamping mechanism 200 . The clamping mechanism 200 includes a concentric positioning part 210 , a front positioning part 220 and a middle positioning part 230 . The concentric positioning part 210 includes a tilting arm positioning component 211 , a tilting arm concentric component 212 , a casting body concentric component 213 and an auxil...

Embodiment 2

[0059] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the support frame 110 is movably connected with the base frame 100 . The bottom frame 100 is provided with a driving mechanism 300 for driving the supporting frame 110 . The driving mechanism 300 includes a lifting part 310 and a rotating part 320 .

[0060] refer to Figure 9The lifting part 310 includes a lifting hydraulic cylinder 311 fixedly connected with the chassis 100. The lifting hydraulic cylinder 311 is vertically arranged and its piston rod is fixedly connected with a lifting plate 312. The tightening component 314 is detachably connected to the support frame 110 . The clamping assembly 314 includes a first mounting plate 3141 fixedly connected to the rotating plate 313, the first mounting plate 3141 is rotatably connected to a second mounting plate 3142, and the support frame 110 can be pressed against the first mounting plate 3141 and the second mounting plate 3142 betwe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap