Jacket type center frame clamp of numerical control equipment

A numerical control equipment, jacket-type technology, applied in metal processing equipment, clamping, manufacturing tools, etc., can solve problems such as failure to meet design requirements, thread deformation, high pressure, etc., to achieve low cost, small deformation of parts, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

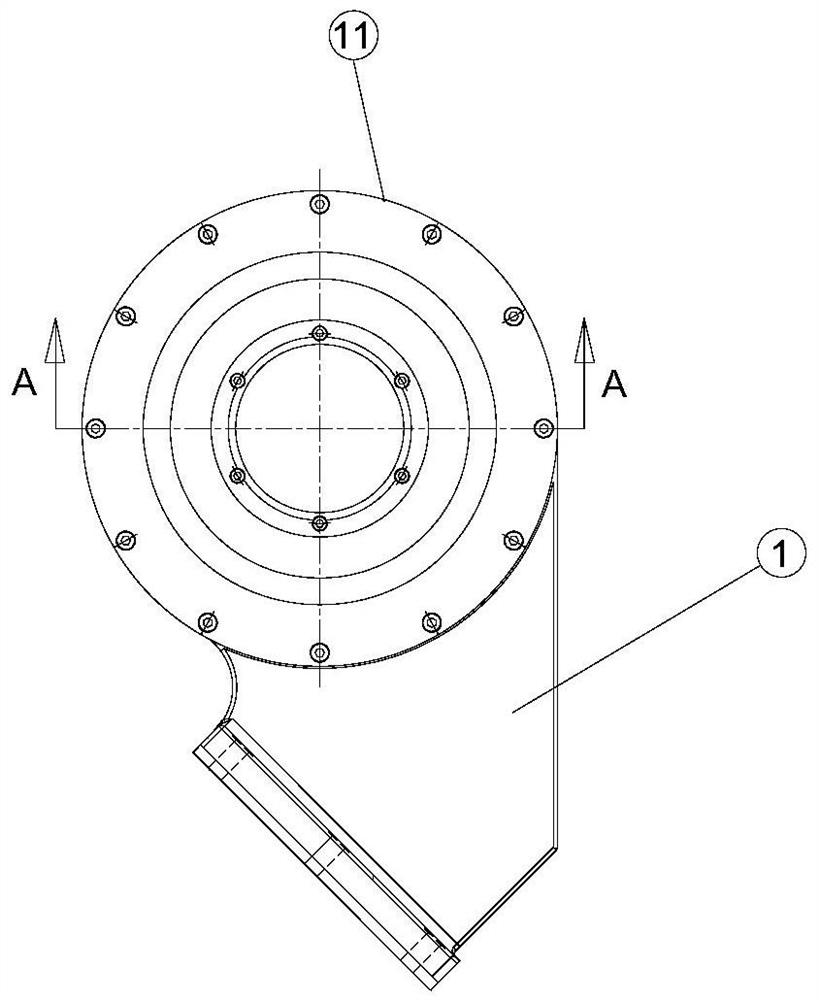

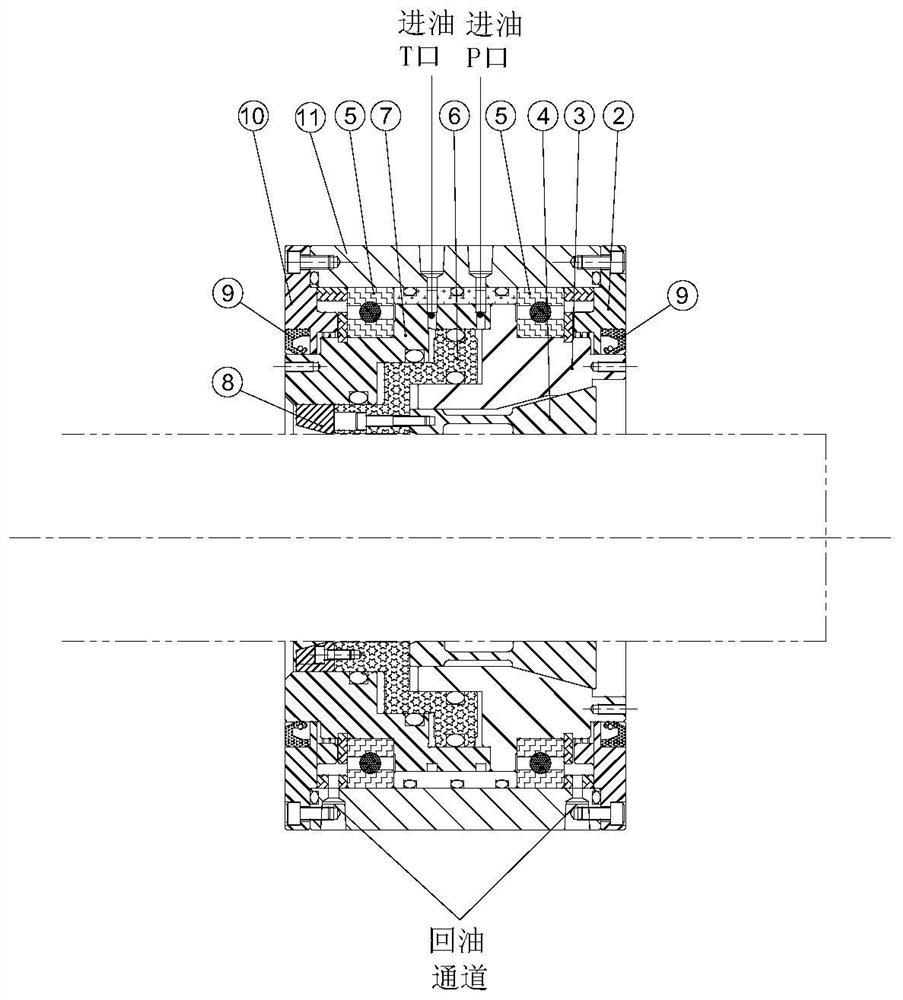

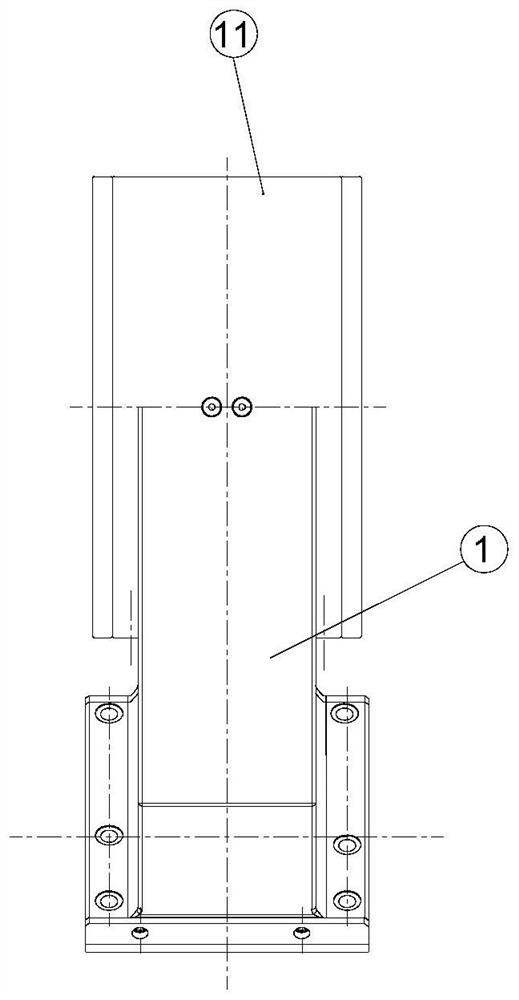

[0019] refer to Figure 1 to Figure 3 , a jacket type center frame clamp for numerical control equipment in the present invention, comprising a clamp base 1, an end cover 2, a jacket seat 3, a jacket 4, a bearing 5, a piston 6, an oil cylinder body 7, and a rear cover 10, the clamp There is an installation base 11 on the base 1, and the jacket seat 3 and the oil cylinder body 7 are respectively installed on both ends of the installation base 11 through bearings 5, and the jacket seat 3 is used for precise positioning when the jacket is clamped The outer side of the jacket seat 3 facing away from the cylinder body 7 is provided with an end cover 2, the outer side of the oil cylinder body 7 facing away from the jacket seat 3 is provided with a rear cover 10, and the oil cylinder body 7 faces the jacket seat One end of 3 has an oil chamber, and the oil cylinder body 7 is also provided with an oil inlet P port, an oil inlet T port and an oil return passage connected with the oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com