Greenhouse vegetable picking and transporting equipment and using method thereof

A technology for transporting equipment and vegetables, which is applied in the field of greenhouse vegetable picking and transporting equipment, can solve the problems of low picking efficiency, achieve the effects of improving picking efficiency, reducing labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

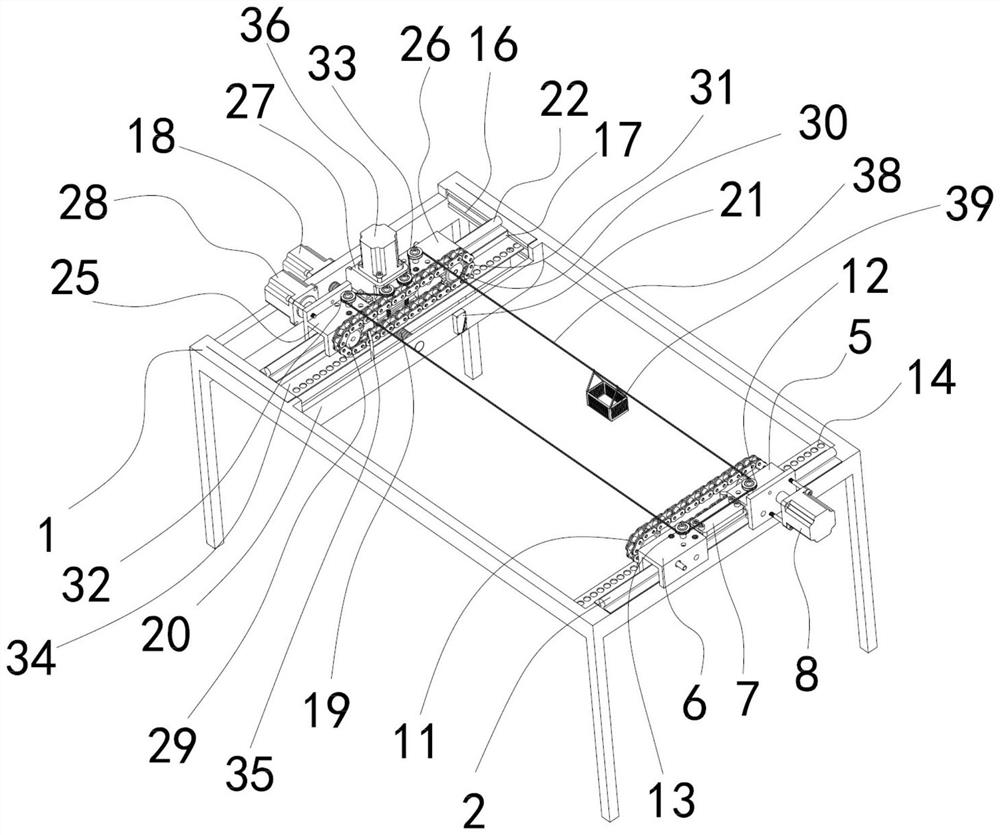

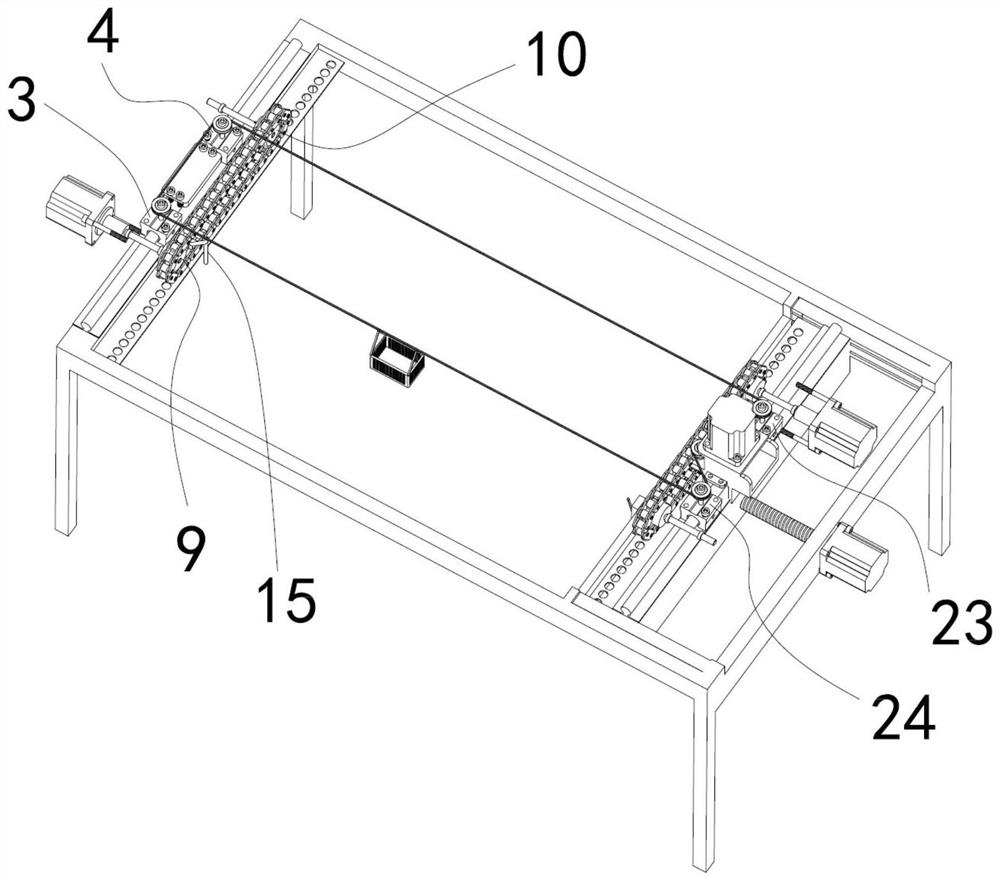

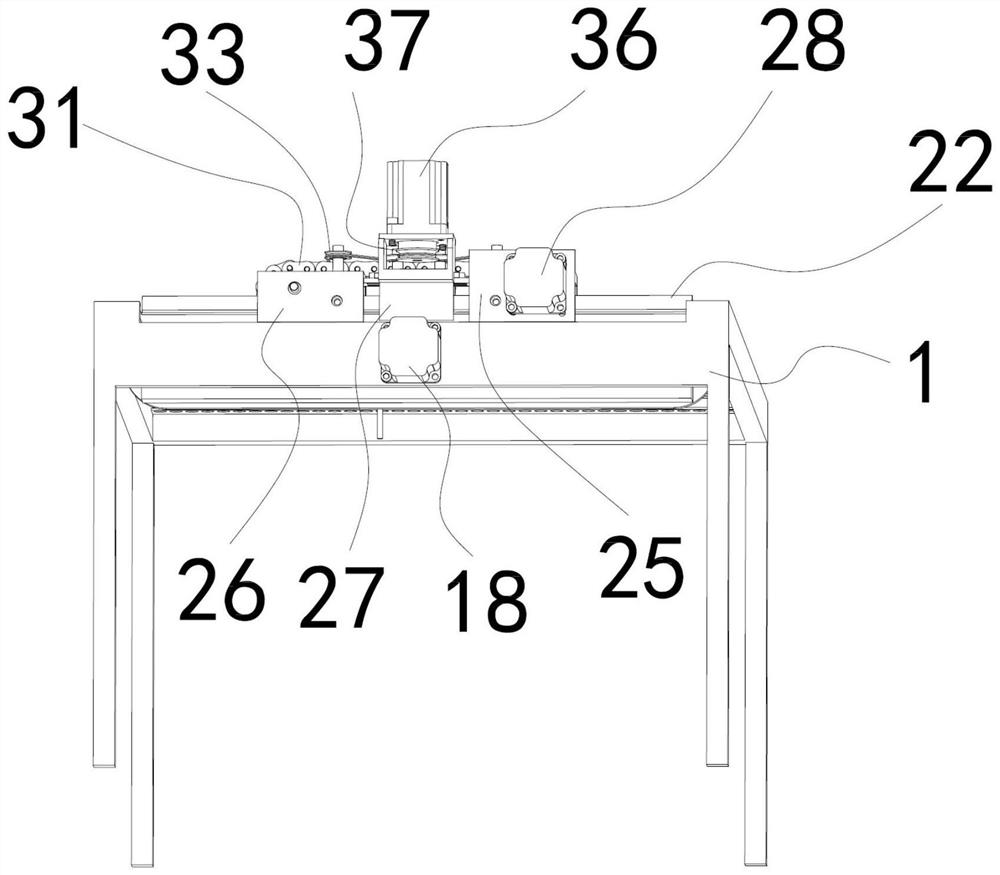

[0034] Referring to the accompanying drawings, the present invention provides a greenhouse vegetable picking and transportation equipment, including a scaffolding 1, characterized in that a guide rail-2 is installed on one side of the scaffolding, and a guide rail slider-3 and a guide rail sliding block are installed on the guide rail-2. Block two 4, the driven wheel support plate one 5 is installed on the guide rail slider one 2, the driven wheel support plate two 6 is installed on the guide rail slider two 4, the driven wheel support plate one 5 and the driven wheel support plate two 6 pass through the connecting plate 7 fixed connections;

[0035] In the driven wheel support plate-5, the side outside the shed is equipped with a mobile motor-8, and the transmission shaft of the mobile motor-8 transmission shaft is installed with a sprocket wheel-9 after passing through the driven wheel support plate-5; in the driven wheel support plate two 6 , a sprocket two 10 is installed ...

Embodiment 2

[0046] On the basis of the structure of Embodiment 1, the steel wire rope 38 is provided with a hook joint, and two hook joints are arranged in the steel wire rope, both of which are arranged in the middle position. After the hook joint is disassembled, the steel wire rope is put away and the equipment is moved.

Embodiment 3

[0048] On the basis of the structure of Embodiment 1, another sensor is installed on the first clamping plate 14 . The position sensor installed at the limit plate 20 places is corresponding to the first transport wire rope; the other position sensor is corresponding to the second transport wire rope, and two reciprocating steel wire ropes can be hung with holding baskets 39 respectively to separate the fruits and vegetables. Shipped to both ends of the land.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com