Conveying mechanism capable of being applied to screen printing machine, gilding press and labeling machine

A conveying mechanism, bronzing machine technology, applied in conveyors, labeling machines, screen printing machines, etc., can solve problems affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1, the concrete structure of the present invention is as follows:

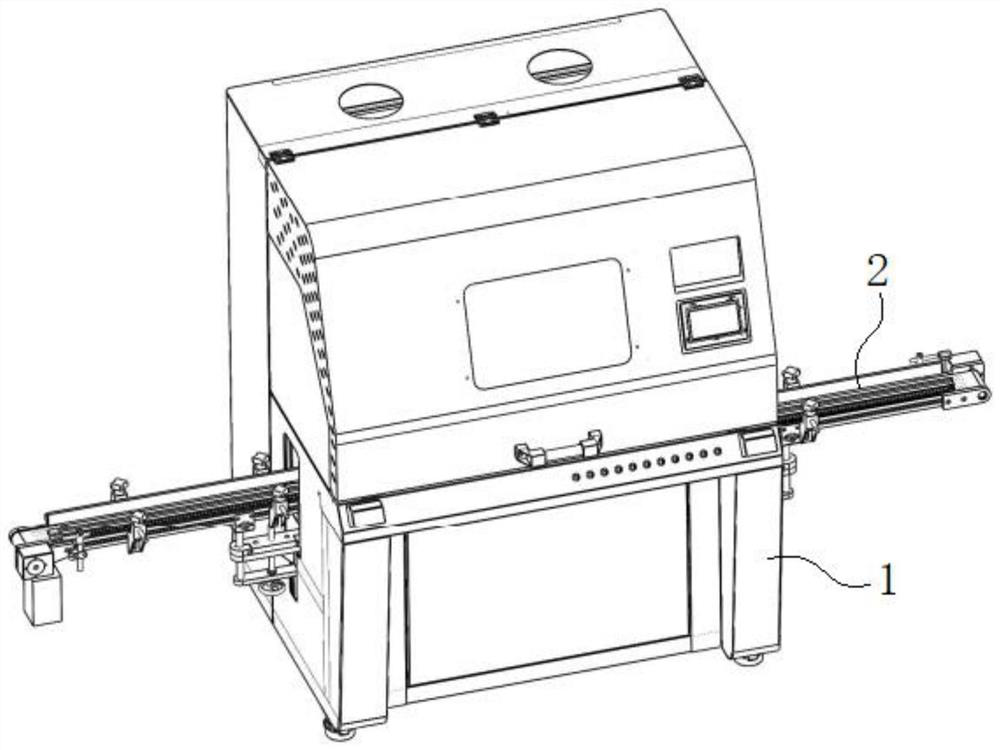

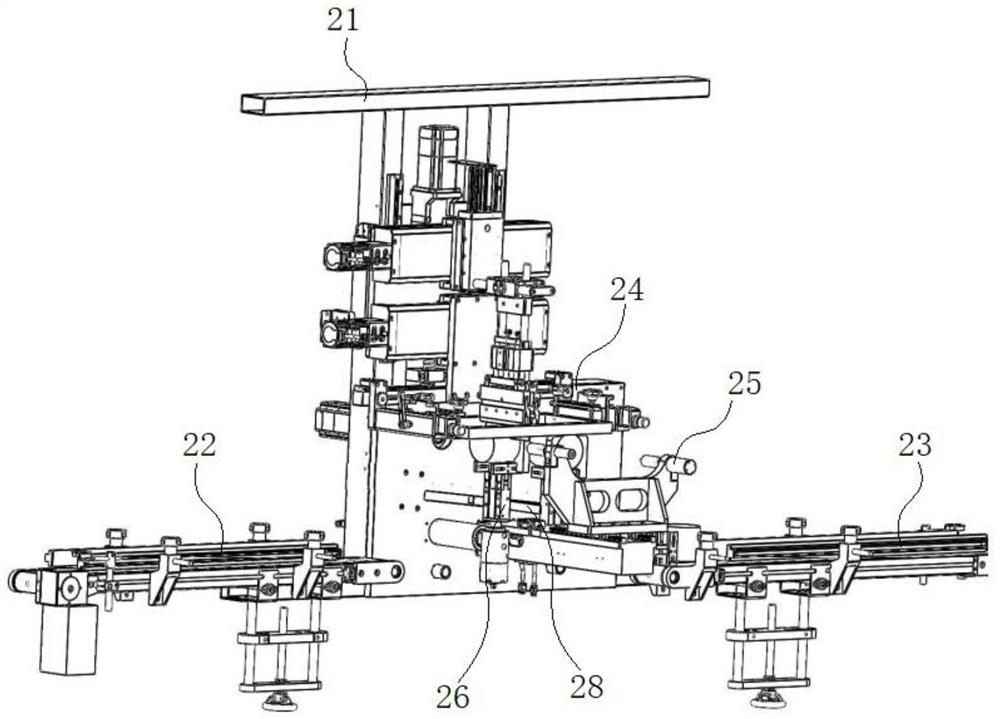

[0054] Please refer to the attached Figure 1-8 , a conveying mechanism of the present invention that can be applied to screen printing machines, bronzing machines and labeling machines, the conveying mechanism 2 is installed on a frame 1, and includes a feeding conveying line 22 and a discharging conveying line 23, the conveying mechanism 2 Institutions also include:

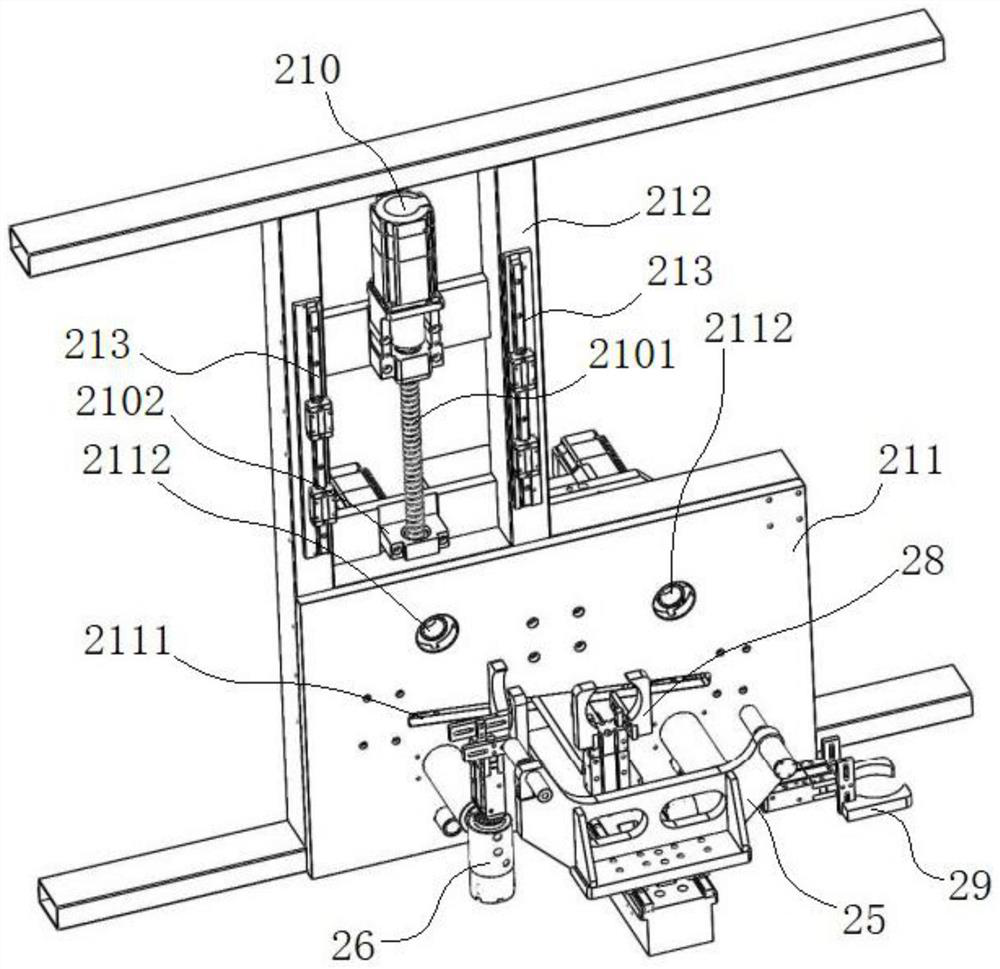

[0055] The bracket assembly 21 is fixed in the frame 1 and has a structural frame 212 and a mounting plate 211 mounted on the structural frame 212. The body of the mounting plate 211 is provided with a pair of via holes in a dislocation arrangement. 2112. An inclined elongated hole 2111 provided on the lower side of the via hole 2112, wherein the high-position via hole is correspondingly arranged above the high-position area of the inclined elongated hole 2111, and the low-position via hole is correspondingly arranged above...

Embodiment 2

[0088] The following is the working principle of the conveying mechanism of the present invention:

[0089] Step one, such as figure 2 As shown, taking the bottle product as an example, the bottle needs to be screen-printed, and the processing mechanism 24 is a silk-screen mechanism, and the bottle is sent to the feeding place from the feeding conveyor line 22 standing;

[0090] Step two, such as Figure 5 , 8 As shown, in the initial state: the overturning part 262 is erected, the clamping part 263 makes the first jaw 264 open and the opening direction is perpendicular to the installation plate 211, at this time, the rotation driving part 261 drives the overturning part 262 to turn left Rotate at an angle of 90 degrees, so that the opened first jaw 264 reaches the bottle side, and the connecting shaft between the turning part 262 and the rotating driving part 261 is covered with an orientation bushing 265;

[0091] Step 3, the clamping part 263 drives the first jaw 264 to...

Embodiment 3

[0100] The conveying mechanism of the present invention can also deliver the product from the low jacking station to the high jacking station. Specifically, the low jacking station is provided with a feeding station, and the high jacking station is set as a processing station. And set the unloading mechanism beside the high top tight station.

[0101] To sum up, since there is a drop between the high top tight station and the low top tight station, when the silk screen printing mechanism works at the high top tight station, it will not touch the screen printing at the low top tight station. bottle. In this way, the present invention can perform operations such as silk screen printing, bronzing or labeling on various products of different specifications and sizes.

[0102] The transfer mechanism of the conveying mechanism of the present invention is transported from high to low, so that the processing mechanism will not touch the products at the unloading station, and also ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com