A device and method for recovering by-product oxygen in hydrogen production from electrolyzed water by using low temperature method

A technology of water electrolysis and low temperature method, applied in the field of hydrogen and oxygen production, can solve the problem of waste of by-product oxygen, and achieve the effects of saving energy, high pressure and reducing reheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

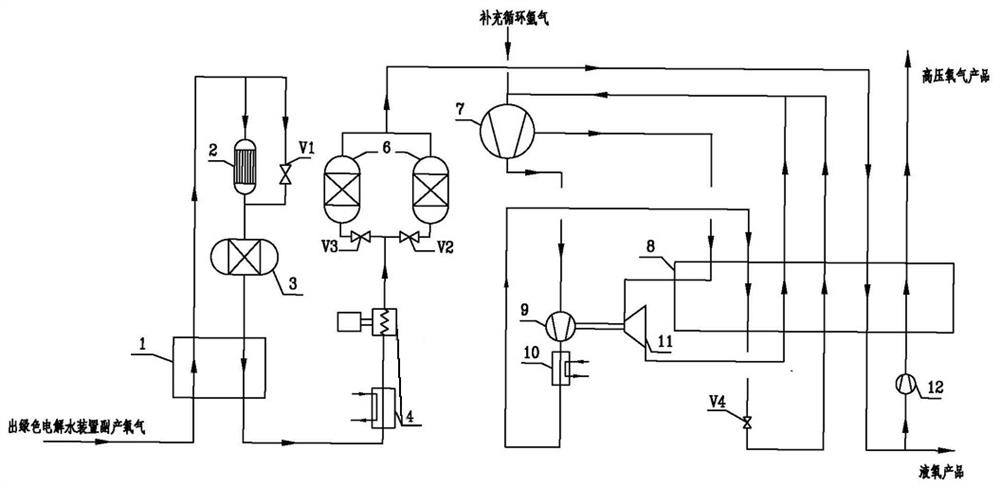

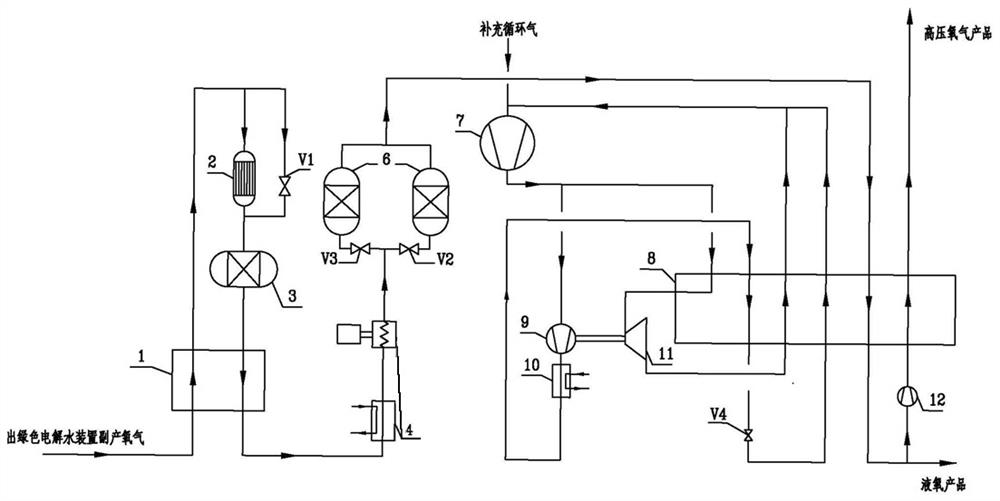

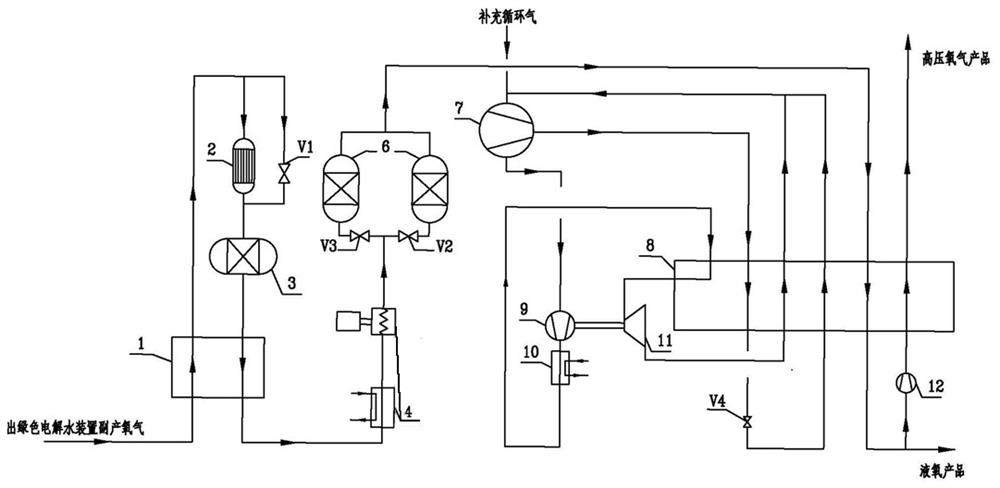

[0034] attached figure 1 Shown is a safe and efficient device that adopts a two-stage pressurized single-expansion process to recover green electrolyzed water to produce hydrogen by-product oxygen by low-temperature method.

[0035] The pressure of the green electrolytic water hydrogen production system is about 1.6MPaG. The by-product oxygen first enters the oxygen purification system. In the oxygen purification system, the oxygen first converts H 2、 Impurities such as CO react into H 2 O and CO 2 etc.; then in the oxygen purifier 6, the H in the oxygen 2 O.CO 2 Wait for the adsorption, the CO in the oxygen after leaving the oxygen purifier 6 2 and H 2 The O content is not greater than 1ppm; the purified oxygen is sent to the plate heat exchanger 8, and is cooled to a liquid state by the backflow cold fluid in the plate heat exchanger 8; then part of the liquid oxygen is sent to the liquid oxygen pump 12, and then 12 is pressurized to 8.7MPaG high-pressure liquid oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com