Addition type liquid silicone rubber as well as preparation method and application thereof

A liquid silicone rubber, addition molding technology, applied in the field of silicone rubber, can solve the problems of easy generation of bubbles, high viscosity, easy oil production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the terminal hydrogen-containing silicone oil with a hydrogen content of 0.3%: 15g of tetramethyldisiloxane, 80g of octamethylcyclotetrasiloxane, 5g of tetramethylcyclosiloxane, 15g of cation exchange The resins were mixed and reacted for 6 hours under the condition of 80° C. to obtain the terminal hydrogen-containing silicone oil.

[0050] The preparation method of the terminal hydrogen-containing silicone oil with a hydrogen content of 0.25%: 6g of tetramethyldisiloxane, 84g of octamethylcyclotetrasiloxane, 10.5g of methyl-terminated side chain hydrogen-containing silicone oil (containing Hydrogen content 1.6%), 15g of cation exchange resins were mixed, reacted under the condition of 80 ℃ for 6 hours, and obtained terminal hydrogen-containing silicone oil.

[0051] The preparation method of the terminal hydrogen-containing silicone oil with a hydrogen content of 0.15%: 8g of tetramethyldisiloxane, 85g of octamethylcyclotetrasiloxane, 2g of te...

Embodiment 1

[0057] The embodiment of the present application provides a kind of addition type liquid silicone rubber, the method comprises:

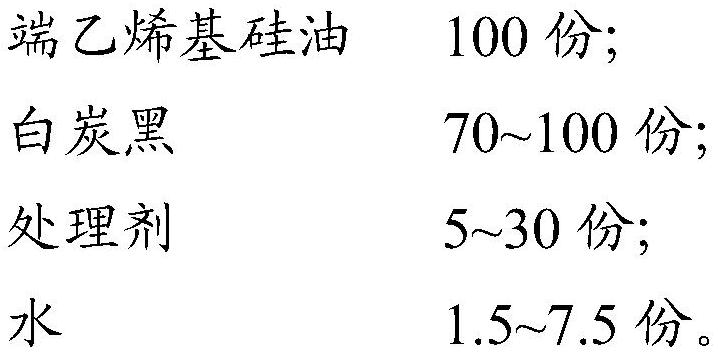

[0058] 1. Add 100 parts by mass of vinyl polydimethylsiloxane with a viscosity of 5000mpa.s into the kneader, stir evenly, and then add 70 parts by mass of 2 / g precipitated white carbon black, 6 parts by mass of hexamethyldisilazane, and 1.5 parts by mass of water were stirred in a kneader for 3 hours, then heated to 180°C for 4 hours in vacuum heat treatment, discharged, and passed through three rolls Grinder to get the base glue.

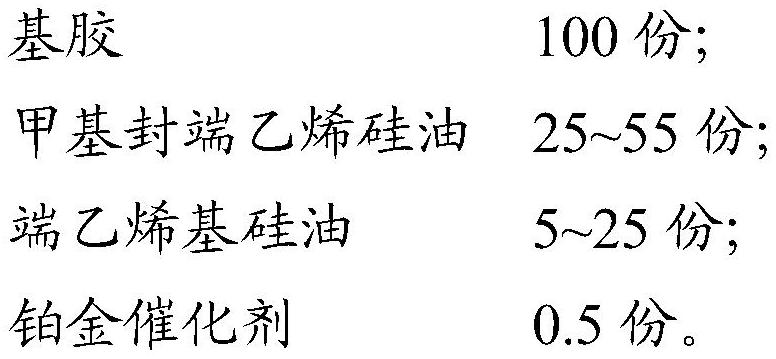

[0059] 2. Add 100 parts by mass of the above rubber base, add 40 parts by mass of methyl-terminated vinyl silicone oil with a viscosity of 100mpa.s, add 10 parts by mass of vinyl-terminated polydimethylsiloxane with a viscosity of 2000mpa.s, and add platinum 0.5 parts by mass of the catalyst (2000PPM of the vinyl complex) was uniformly stirred in a planetary mixer to prepare Agent A.

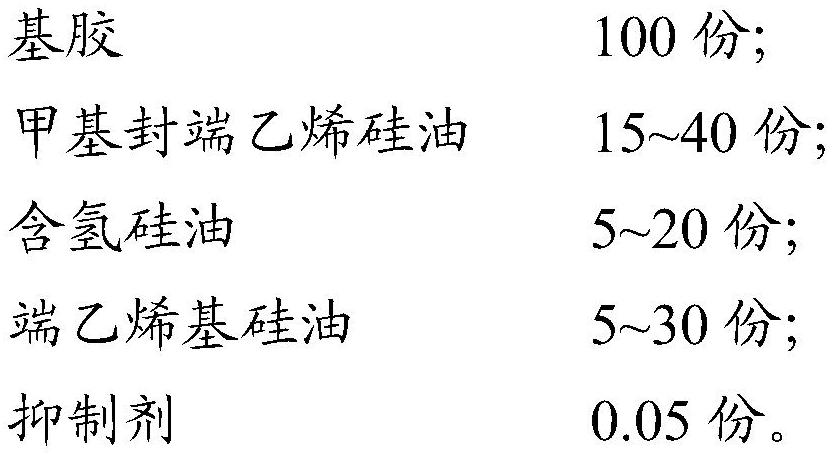

[0060] 3. Add 100 parts by mass...

Embodiment 2

[0064] The embodiment of the present application provides a kind of addition type liquid silicone rubber, the method comprises:

[0065] 1. Add 100 parts by mass of vinyl polydimethylsiloxane with a viscosity of 5000mpa.s into the kneader, stir evenly, and then add 70 parts by mass of polydimethylsiloxane with a specific surface area of 180m 2 / g precipitated white carbon black, 6 parts by mass of hexamethyldisilazane, 4 parts by mass of dimethyldiethoxysilane, and 2 parts by mass of water were stirred in a kneader for 3 hours, then heated to 180°C Vacuum heat treatment for 4 hours, discharge, and pass through a three-roll mill to obtain base rubber.

[0066] 2. Add 100 parts by mass of the above rubber base, add 40 parts by mass of methyl-terminated vinyl silicone oil with a viscosity of 100mpa.s, add 10 parts by mass of vinyl-terminated polydimethylsiloxane with a viscosity of 200mpa.s, and add platinum 0.5 parts by mass of the catalyst (2000PPM of the vinyl complex) was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com