Preheater device for blast furnace hot blast stove

A hot blast stove and preheater technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as poor preheating effect and inconvenient cleaning of dust, saving trouble and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

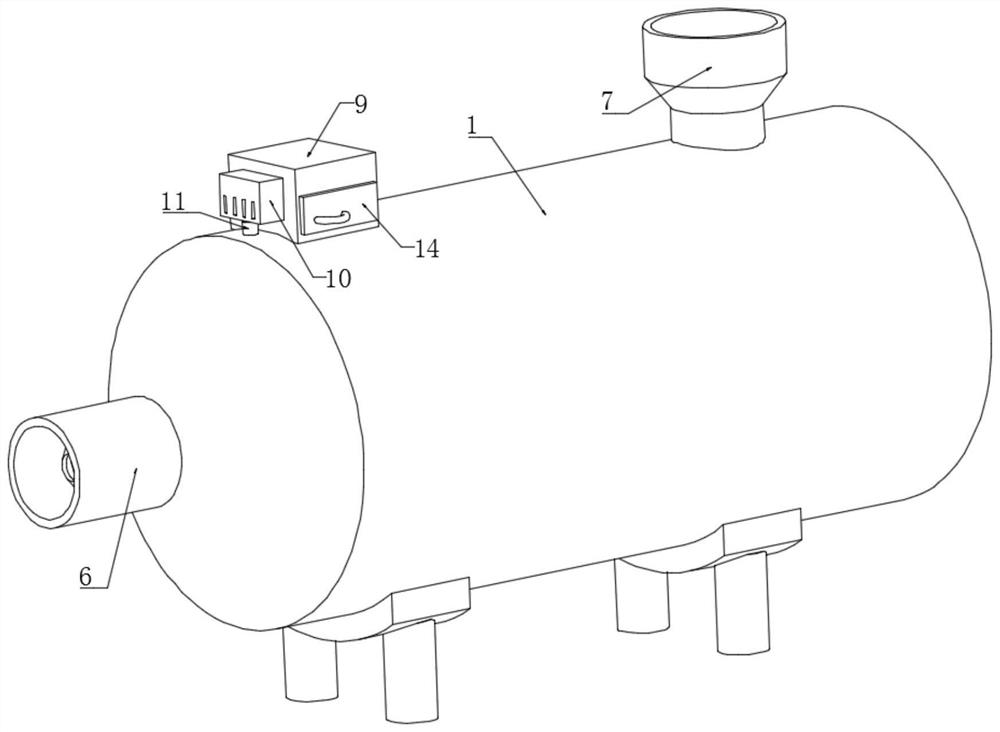

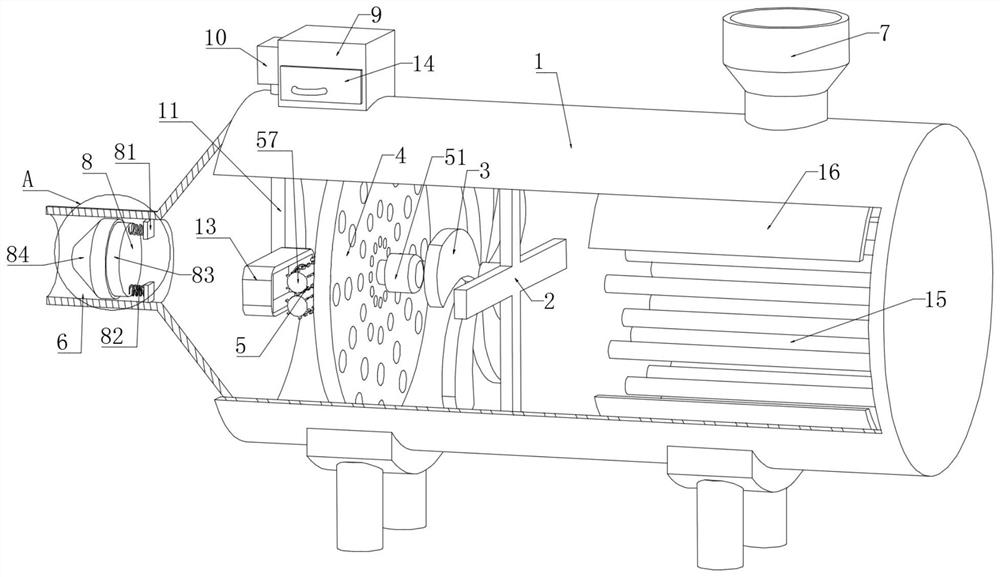

[0029] Embodiment 1: A preheater device for a blast furnace hot blast stove, comprising a preheating barrel 1, a cross support 2 is fixedly connected to the inner cavity wall of the preheating barrel 1, and an exhaust fan 3 is arranged on the left side wall of the cross support 2 to preheat The inner cavity wall of the barrel 1 is fixedly connected with a filter plate 4, the left side wall of the filter plate 4 is provided with a cleaning mechanism 5, the left end surface of the preheating barrel 1 is connected with an air inlet pipe 6, and the upper end surface of the preheating barrel 1 is provided with an outlet pipe. The air duct 7, the inner chamber wall of the air inlet duct 6 is provided with a sealing mechanism 8, the upper end surface of the preheating barrel 1 is provided with a dust collection mechanism 10, and the right side wall of the dust collection mechanism 10 is fixedly connected with a collection box 9, and the dust suction mechanism The lower end surface of ...

Embodiment 2

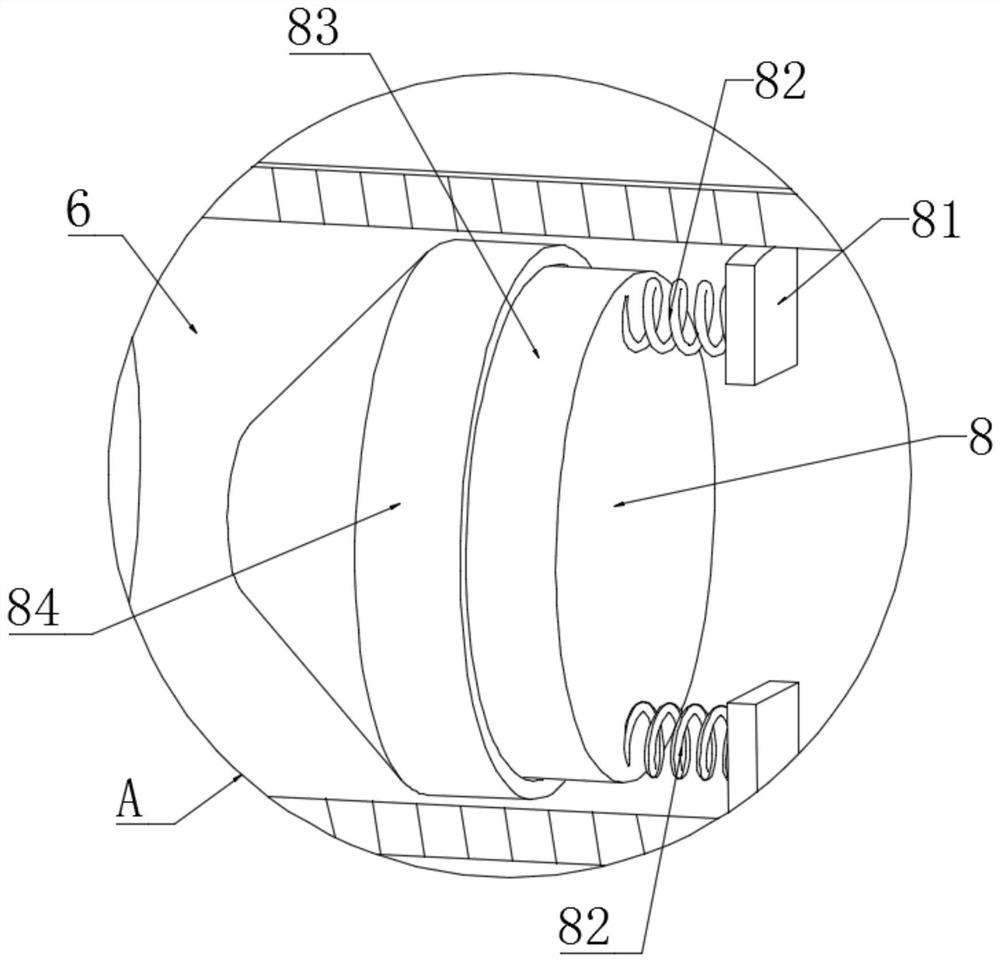

[0030]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sealing mechanism 8 includes a mounting block 81, a spring 82, a tapered column 83 and a tapered sleeve 84, and the inner cavity wall of the air inlet pipe 6 is symmetrically fixedly connected with a mounting block 81 , a spring 82 is fixedly connected to the left side wall of the mounting block 81 . The left end of the spring 82 is fixedly connected with a tapered column 83, the inner cavity wall of the air inlet pipe 6 is fixedly connected with a tapered sleeve 84, the inner wall of the tapered sleeve 84 is engaged with the tapered column 83, and the preheating barrel 1 is close to the right side The inner cavity wall of the preheating bucket 1 is provided with a thermal insulation ring layer 16, and the right cavity wall of the preheating barrel 1 is evenly and fixedly connected with a heat pipe 15. Through the cooperation of the insulation ring layer 16, the heat pipe 15, the sealing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com