Air compressor with small-gap type ring matching structure and type ring machining method

A technology that matches the structure and processing method, and is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., to achieve the effects of low processing cost, increased efficiency, and reduced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

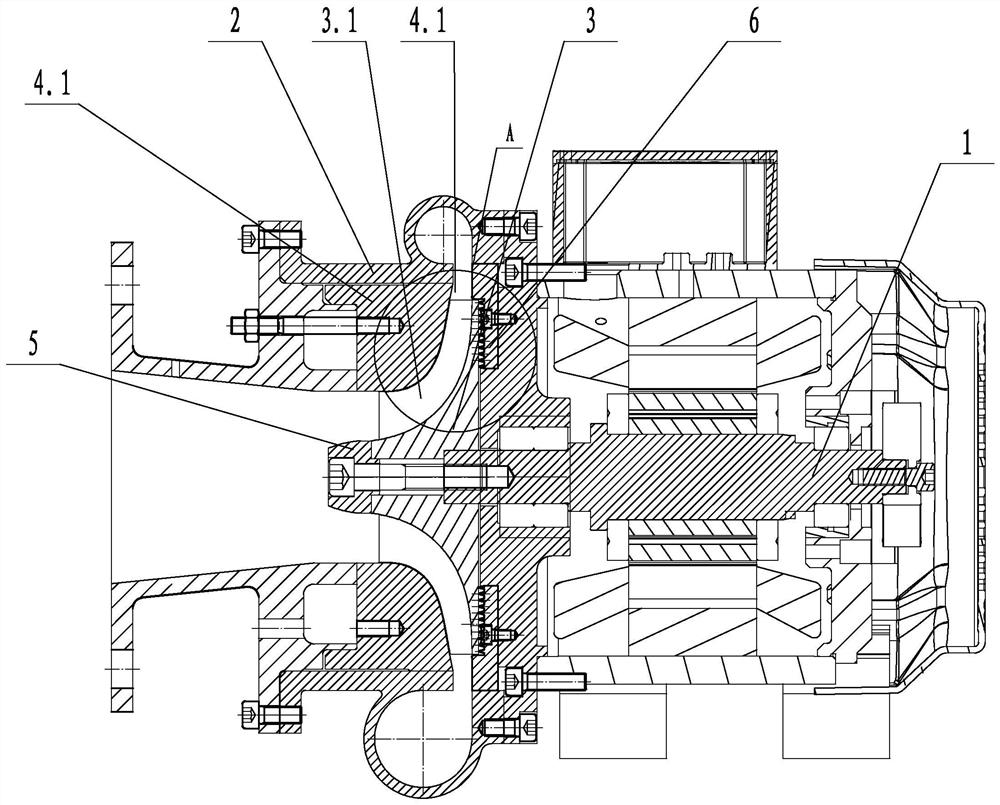

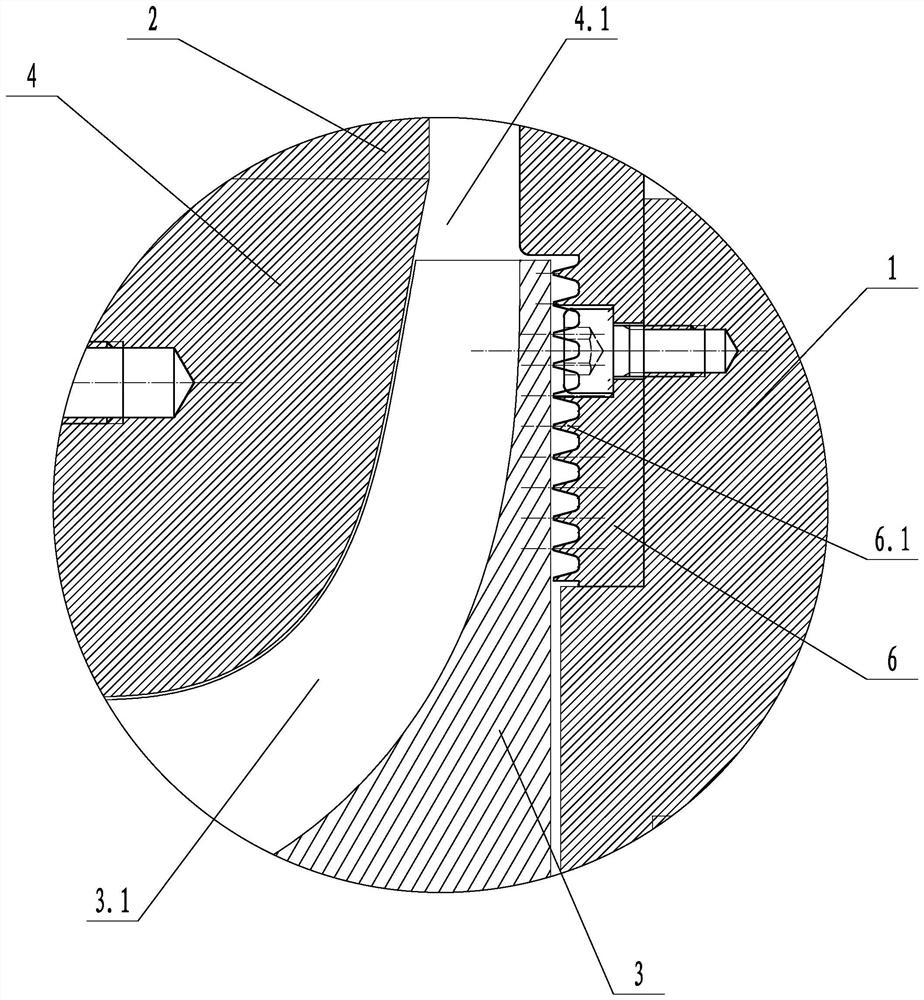

[0031] like figure 1 and figure 2 As shown, an air compressor with a small-gap ring fit structure includes a drive motor 1, a volute 2, an impeller 3 and a ring 4, the volute 2 is fixed to the casing of the drive motor 1, and the impeller 3 and the ring 4 Arranged in the volute 2, the impeller 3 is arranged inside the type ring 4, the impeller 3 is coaxially fixed with the output shaft of the drive motor 1, the type ring 4 is fixed with the volute 2, and the volute 2 is provided with a fairing 5, The fairing 5 is coaxially fixed with the impeller 3 . There is a gap between the inner surface of the type ring 4 and the outer surface of the impeller 3, the width of the gap is less than 0.3 mm, and the material of the type ring 4 is nylon. The impeller 3 is provided with an arc-shaped air guide groove 3.1, the inlet size of the arc-shaped air guide groove 3.1 is larger than the outlet size of the arc-shaped air guide groove 3.1, and the inner size of the arc-shaped air guide gr...

Embodiment 2

[0034] A method for processing an air compressor ring, comprising the following steps:

[0035] a. Rough machining: According to the final size of the ring 4, use the machine tool for rough machining, and reserve a machining allowance;

[0036] b. Sizing installation: Install the type ring 4 on the setting polishing equipment. The setting polishing equipment is designed according to the size of the air compressor. The setting polishing equipment is provided with a polishing wheel. The impeller 3 is the same, in the setting polishing equipment, the type ring 4 is installed opposite to the polishing wheel, in the air compressor, the type ring 4 is installed opposite to the impeller 3;

[0037]c. Shape processing: start the shape polishing equipment, use the polishing wheel to carry out shape processing on the inner surface of the type ring 4, and remove the type ring 4 after the shape processing is completed; polishing particles;

[0038] d. Groove processing: on the inner sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com