Full-automatic noodle maker for food processing

A food processing, fully automatic technology, applied in cutting noodles, application, food science, etc., can solve the problems of reduced production efficiency, inconvenient cleaning and collection, and increased labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

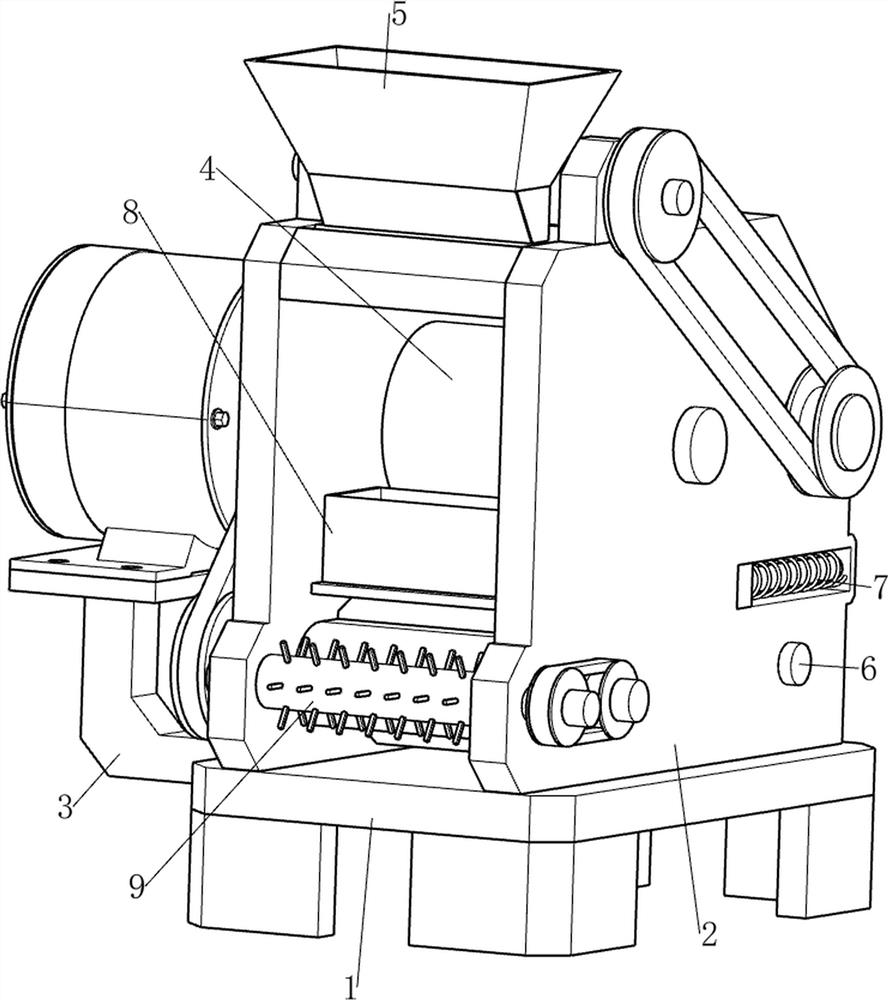

[0059] A full-automatic noodle machine for food processing, such as Figure 1-4 As shown, it includes a base 1, a casing 2, a first support frame 3, a molding assembly 4 and a blanking assembly 5, the base 1 is provided with a casing 2, the front side of the middle part of the base 1 is provided with a first support frame 3, the casing 2 and the A molding assembly 4 is provided on the first support frame 3 , and a blanking assembly 5 is provided on the top of the casing 2 .

[0060] When people need to make noodles, they can use this equipment. First, people put the dough into the 5 parts of the blanking assembly, start the forming assembly 4, and make the 4 parts of the forming assembly drive the 5 parts of the blanking assembly to rotate. When the dough and the blanking assembly 5 When the parts are in contact, the 5 parts of the blanking component press the dough into dough, and then the 5 parts of the blanking component drive the dough to move to the 4 parts of the forming...

Embodiment 2

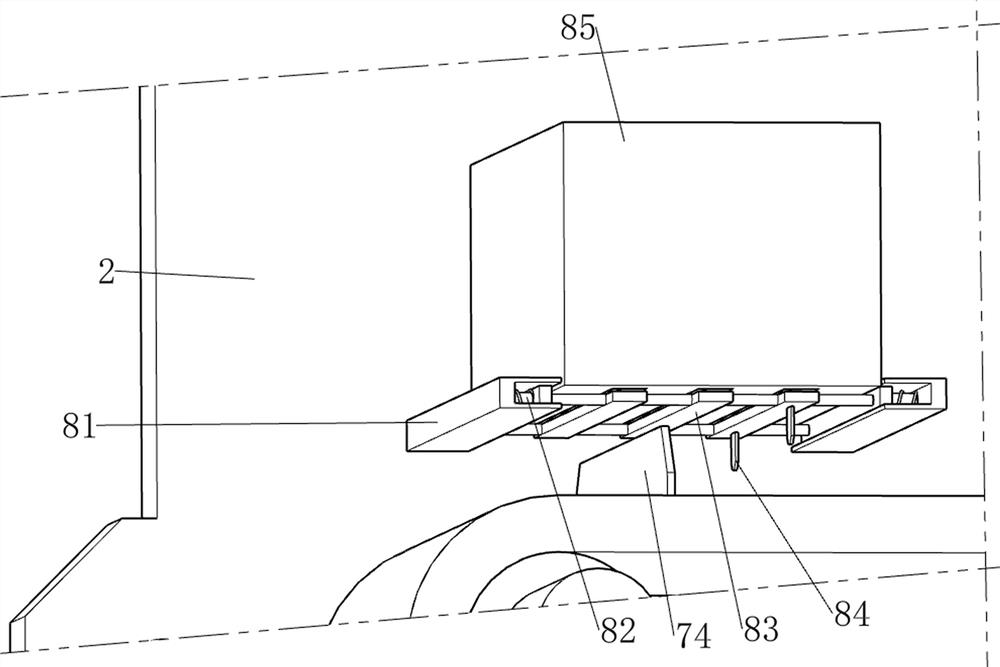

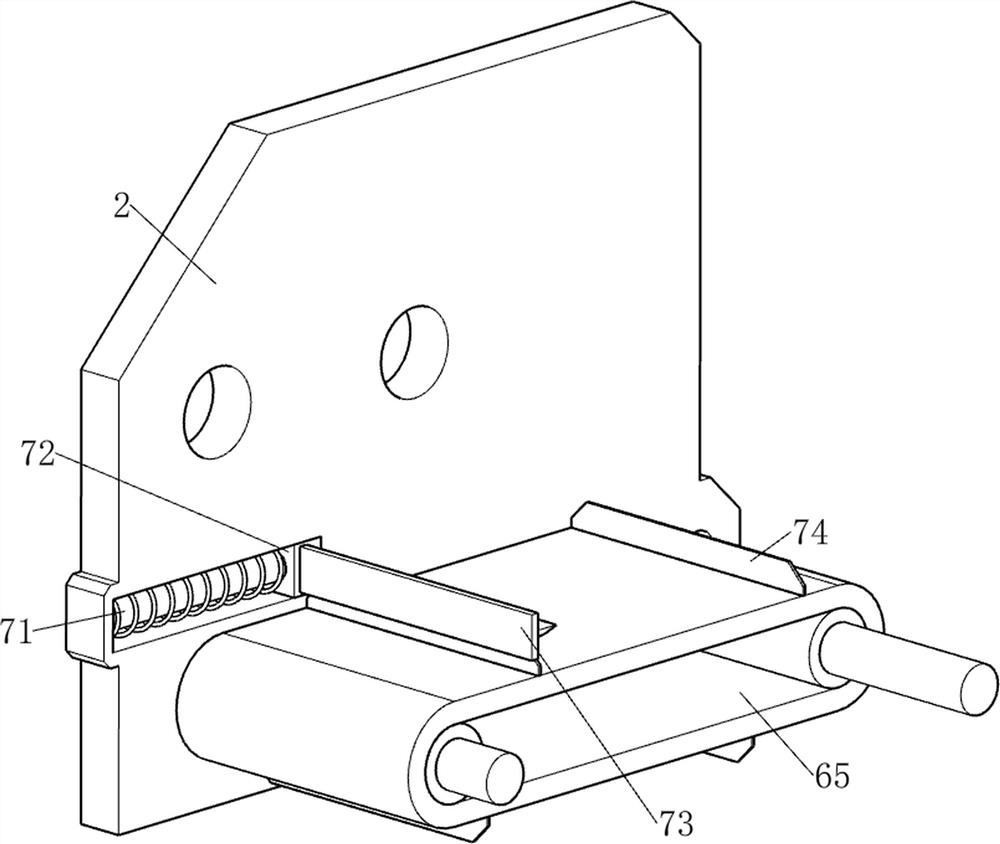

[0066] On the basis of Example 1, such as Figure 5-8 As shown, a discharge assembly 6 is also included, and the discharge assembly 6 includes a fourth rotating shaft 61, a second belt 62, a fifth rotating shaft 63, a third roller 64, a conveyor belt 65, a baffle plate 66 and a second scraper 67, A fourth rotating shaft 61 is rotatably arranged between the right side of the inner lower part of the housing 2, and a second belt 62 is wound between the front side of the fourth rotating shaft 61 and the front side of the first rotating shaft 42. There is a fifth rotating shaft 63, a third roller 64 is arranged on the fourth rotating shaft 61 and the fifth rotating shaft 63, a conveyor belt 65 is wound between the third rollers 64, a baffle 66 is arranged between the left side of the casing 2, and the baffle 66 is located below the second roller 53 , and a second scraper 67 is provided between the left side of the housing 2 , and the second scraper 67 cooperates with the forming ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com