Dried crayfish nut stick as well as preparation method and application thereof

A technology for lobsters and nuts, which is applied in food preservation, food ingredients as taste improvers, food science, etc. It can solve the problems of unsightly packaging, high production cost, and easy bag breakage, so as to inhibit the migration of moisture and prevent Moisture loss, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

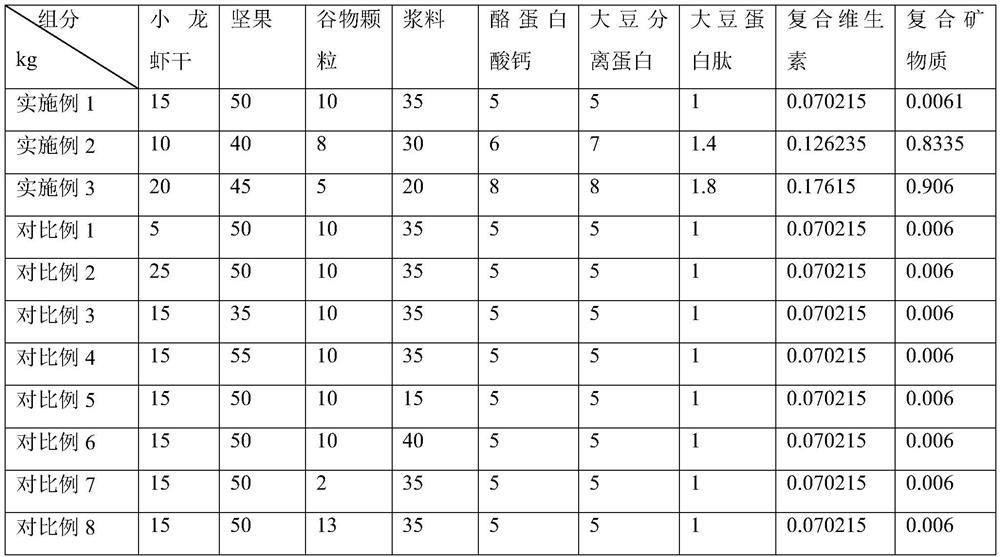

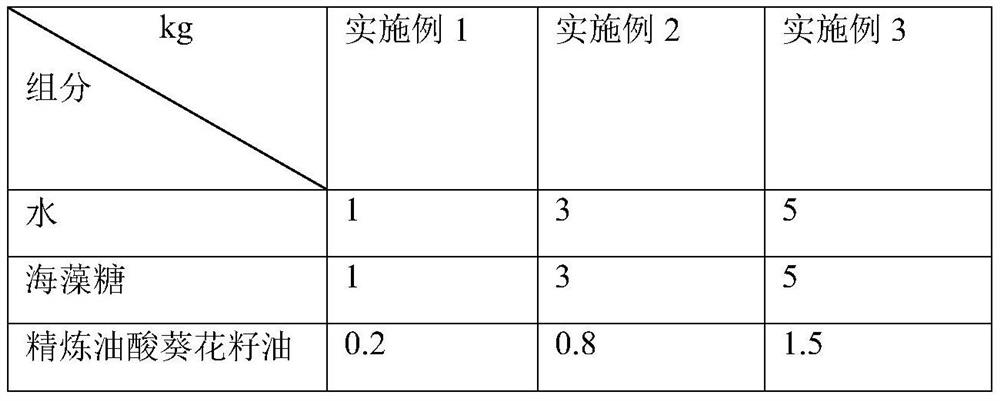

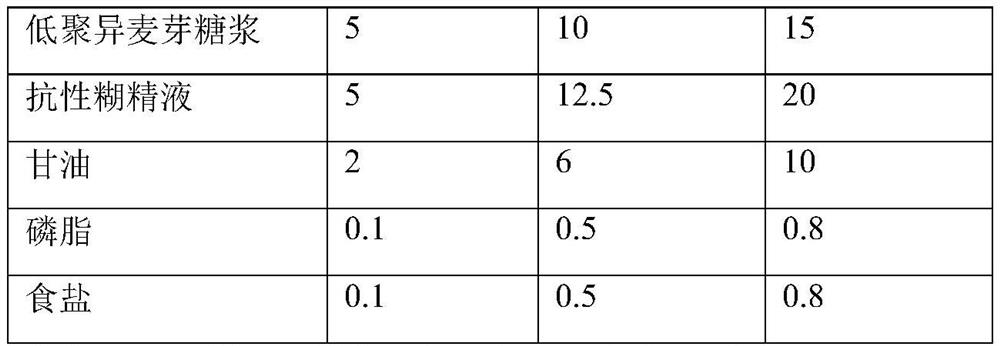

Method used

Image

Examples

preparation example 1

[0038] Preparation example 1: (1) Thaw the crayfish shells and rinse them with clean water twice; (2) Add 100g of sunflower oil to the pot, heat at 110°C for 1min, pour in 150g of spices, stir-fry for 60s, add 1000g Stir-fry crayfish meat at 120°C for 20 minutes. Spices include 4g pepper powder, 60g minced garlic, 20g minced ginger, 20g cooking wine, 50g bean paste, 200g beer, and 12g coconut powder; (3) put the crayfish meat in the oven, Bake at 110° C. for 5 hours to measure the water content and water activity. When the water content is 12% and the water activity is 0.6, the dried crayfish is finished.

preparation example 2

[0039] Preparation example 2: (1) Thaw the crayfish shells and rinse them twice with water; (2) Add 95g of sunflower oil to the pot, heat at 115°C for 1.5min, pour in 152g of spices, stir fry for 30s, add Stir-fry 1000g crayfish meat at 125°C for 23 minutes. Spices include 3g pepper powder, 55g minced garlic, 18g minced ginger, 17g cooking wine, 45g bean paste, 250g beer, and 14g coconut powder; (3) put the crayfish meat in the oven , baked at 115° C. for 5 hours, and measured the water content and water activity. When the water content is 10% and the water activity is 0.6, the dried crayfish is finished.

preparation example 3

[0040] Preparation example 3: (1) Thaw the crayfish shells and rinse them with water twice; (2) Add 105g of sunflower oil to the pot, heat at 120°C for 1min, pour in 154g of spices, stir-fry for 60s, add 1000g Stir-fry crayfish meat at 130°C for 25 minutes. Spices include 5g pepper powder, 65g minced garlic, 22g minced ginger, 23g cooking wine, 55g bean paste, 300g beer, and 16g coconut powder; (3) put the crayfish meat in the oven, Bake at 120° C. for 5 hours to measure the water content and water activity. When the water content is 14% and the water activity is 0.6, the dried crayfish is finished.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com