Automatic flaking device for conductive adhesive

A conductive adhesive and automatic technology, applied in metal processing and other directions, can solve problems such as low work efficiency, errors in parallelism or perpendicularity, and affect the conductivity of conductive films, so as to achieve guaranteed quality, high work efficiency, and improved uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples of the present invention will be described in detail.

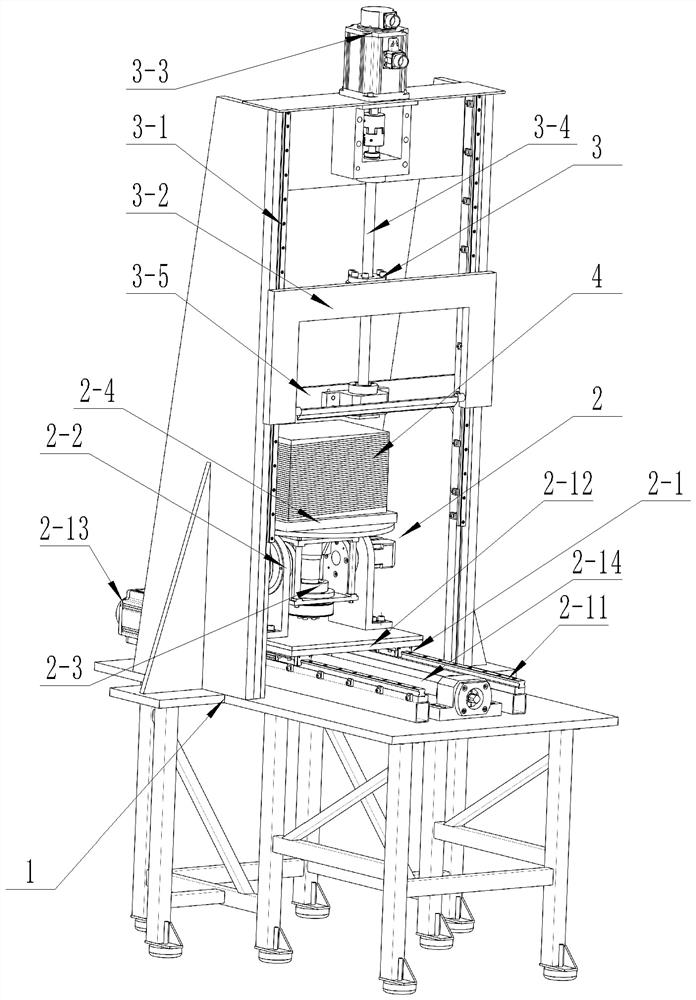

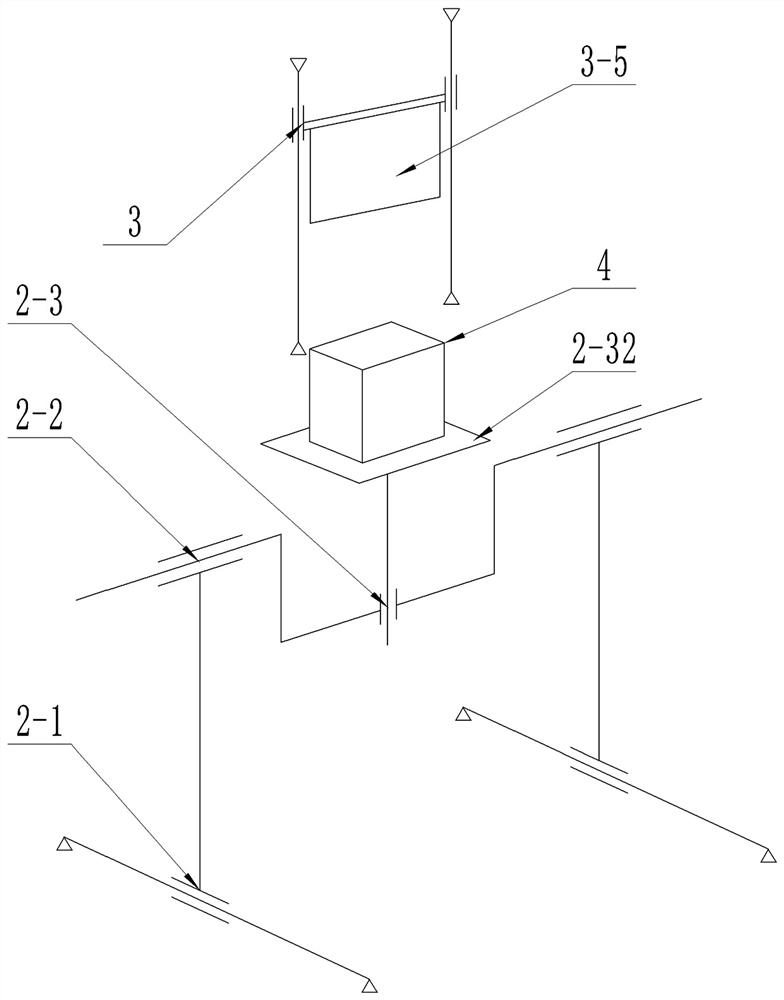

[0023] See Figure 1 to 5 An automatic planing conductive adhesive sheet means, comprising a frame 1, carrying conductive paste platform assembly mounted on the chassis 1, 2, 3 plow assembly and a control module,

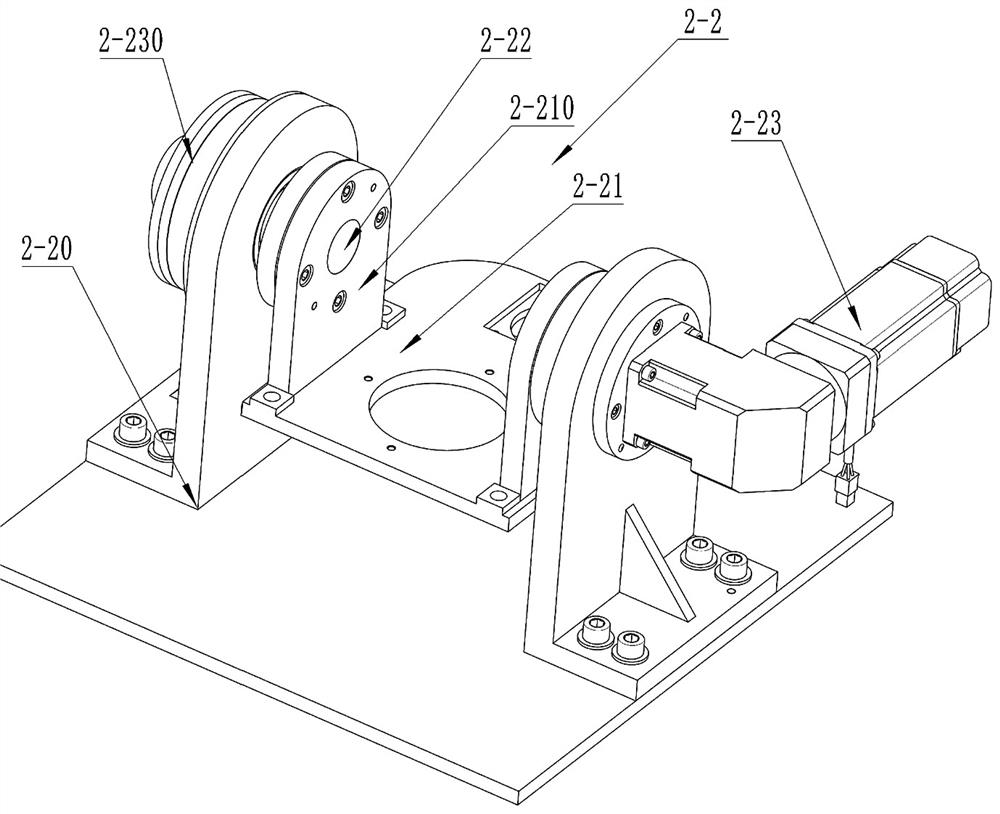

[0024] 2 platform assembly includes a feed mechanism 2-1, 2-2 tilt mechanism, rotation mechanism and the conductive adhesive fixing means 2-3, 2-1 feed mechanism comprises a horizontal guide rail and a horizontal frame 1 provided on the slide table 2- 12, a first horizontal guide rails 2-11, 2-12 horizontal slide table connected to the first drive mechanism, the first drive mechanism includes a first servomotor and a first ball screw 2-13 2-14, a first servo 2-13 motor mounted on the frame 1, a first ball screw 2-14 and 2-11 the first guide rail disposed in parallel, the output terminal end of the first ball screw 2-14 and 2-13 of the first servo motor when connected, the level of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com