Micro-area synchronous curing electronic injection printing device

A printing device and micro-area technology, applied in manufacturing auxiliary devices, processing heating elements, processing data acquisition/processing, etc., can solve the problems of substrate printing structure fracture, thermal deformation, etc., and achieve reduced thermal deformation, low energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

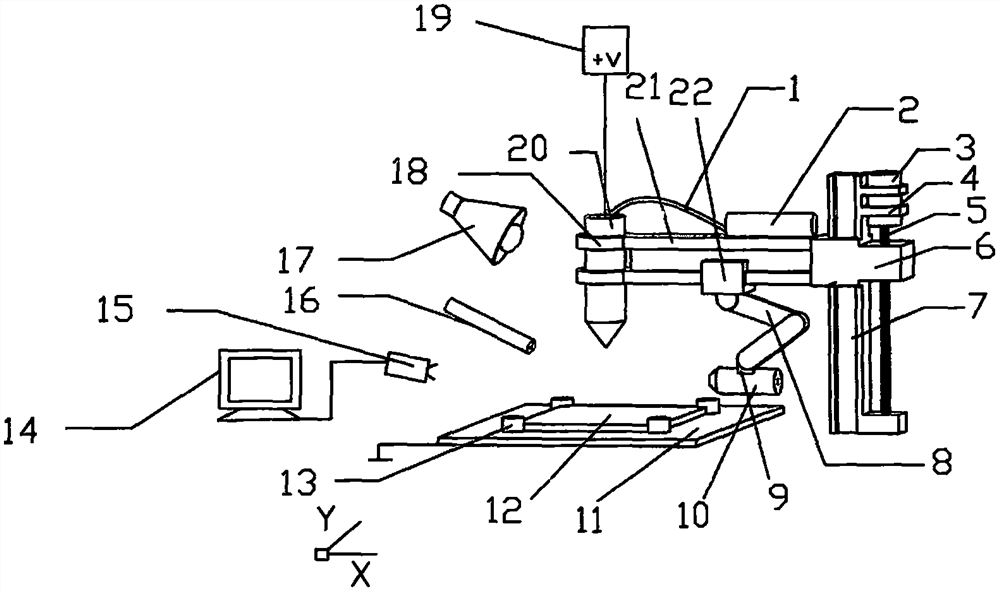

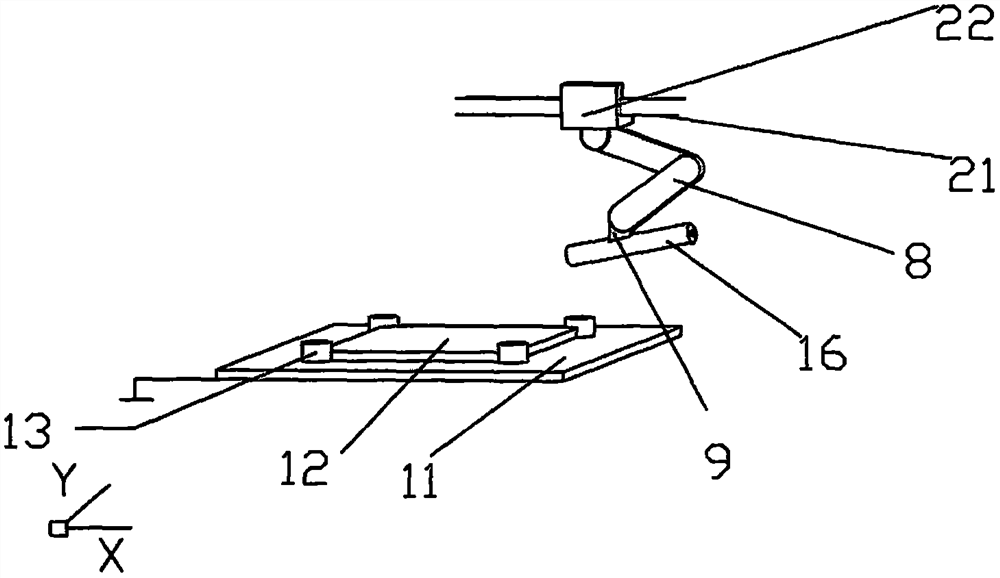

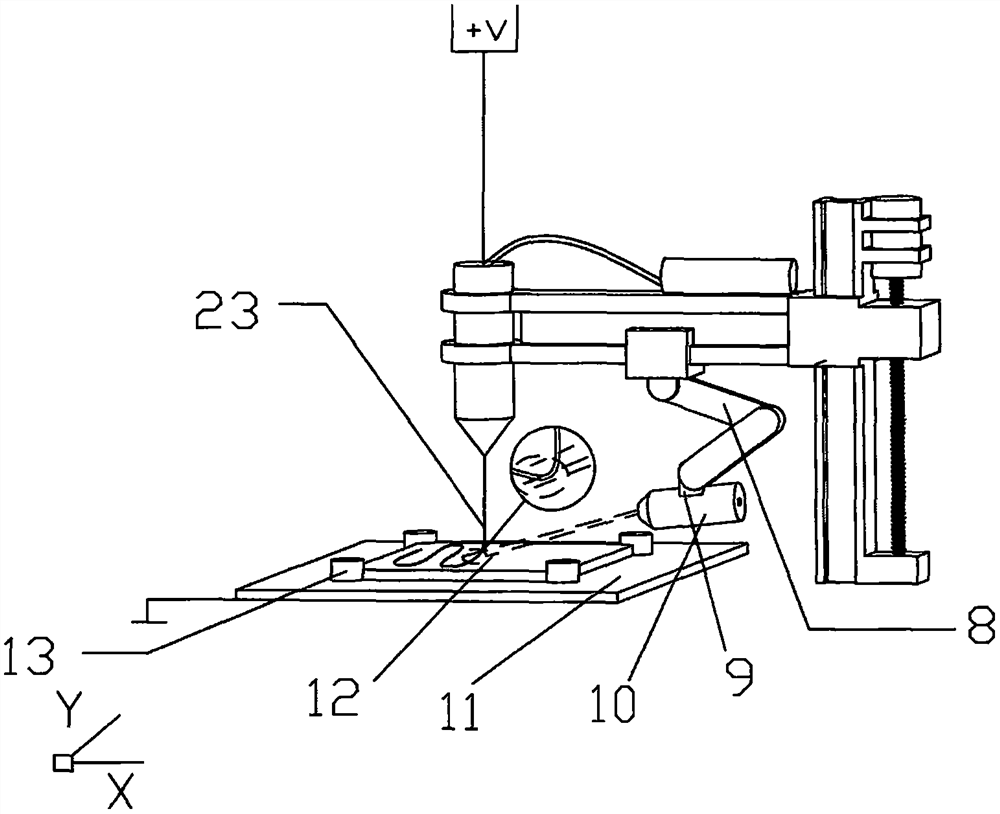

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. see Figure 1 to Figure 3 .

[0021] This example discloses a micro-area synchronous curing electrojet printing device, which includes three parts: a synchronous heating and curing module, a motion adjustment module, and an electrojet printing module. First, the printing ink is output through the syringe pump, and delivered to the electrojet printing nozzle through the connecting conduit. At the same time, the potential regulator makes the printing nozzle have a high potential, and forms a high voltage with the moving substrate. When the ink is delivered to the nozzle of the printing nozzle , under the action of electric field force, gravity and its own surface tension, a fine jet is formed. During the printing process, when the jet is deposited on the printing substrate, the heating device is heated immed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com