Carbon dioxide laser superhard film and preparation method thereof

A technology of carbon dioxide and laser, which is applied in the field of carbon dioxide laser superhard film and its preparation, to achieve the effect of good preparation repeatability, excellent optical performance and strong film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

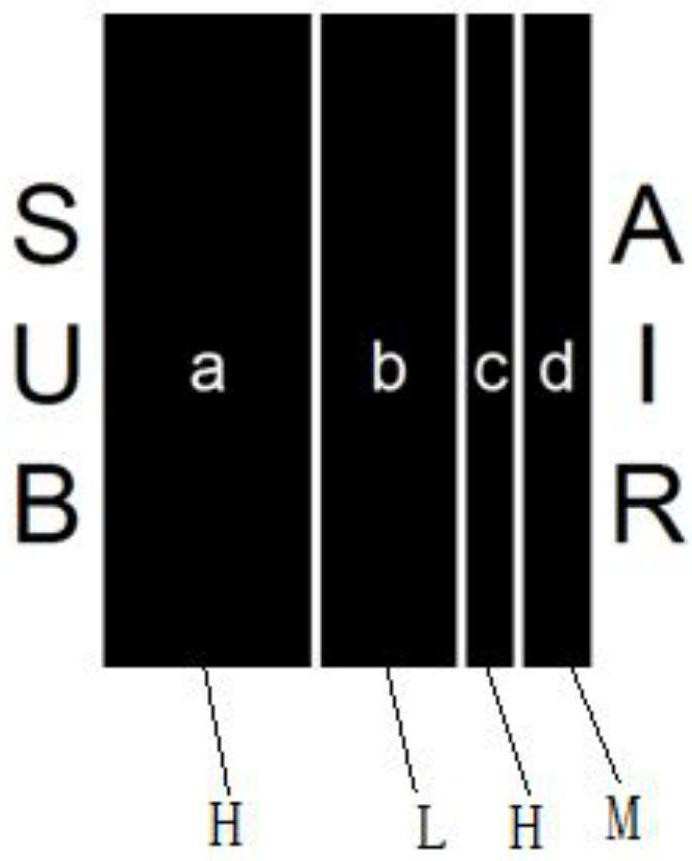

[0027] Such as figure 1 As shown, a carbon dioxide laser superhard film, the film layer structure is: SUB / aHbLcHdM / A, wherein, SUB represents ZnSe substrate, A represents air, H represents Ge, L represents ZnS, M represents DLC; a, b, c and d represent the coefficients of the quarter reference wavelength optical thickness of each layer, a is 5.44, b is 3.18, c is 0.82, and d is 1.27.

[0028] The preparation of the above-mentioned carbon dioxide laser superhard film comprises the following steps:

[0029] 1) Clean the substrate before coating: use a degreasing cloth dipped in a 1:3 mixture of absolute ethanol and ether to wipe to remove residual dirt on the surface.

[0030] 2) Before evaporation, ion bombardment is carried out on the substrate for 5 minutes, and then film deposition is carried out. The evaporation rate of ZnS is controlled at 1nm / s, and the evaporation rate of Ge is controlled at 0.2nm / s. During the process of film deposition, use consideration Fenman ion s...

Embodiment 2

[0034] Such as figure 1 As shown, a carbon dioxide laser superhard film, the film layer structure is: SUB / aHbLcHdM / A, wherein, SUB represents ZnSe substrate, A represents air, H represents Ge, L represents ZnS, M represents DLC; a, b, c and d represent the coefficients of the quarter reference wavelength optical thickness of each layer, a is 4.59, b is 2.62, c is 1.19, and d is 0.17.

[0035]The preparation of the above-mentioned carbon dioxide laser superhard film comprises the following steps:

[0036] 1) Clean the substrate before coating: use a degreasing cloth dipped in a 1:3 mixture of absolute ethanol and ether to wipe to remove residual dirt on the surface.

[0037] 2) Before evaporation, ion bombardment is carried out on the substrate for 5 minutes, and then film deposition is carried out. The evaporation rate of ZnS is controlled at 1nm / s, and the evaporation rate of Ge is controlled at 0.2nm / s. During the process of film deposition, use consideration Fenman ion so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap