Debris collecting device for vertical shaft excavation hole by drilling and blasting method

A technology of collecting device and drilling and blasting method, which is applied in vertical shaft equipment, sinking, earthwork drilling and mining, etc., can solve the problems of slow slag removal speed, influence of slag discharge speed, personal casualties of debris, etc., so as to expand the working scope and eliminate Dangerous, work-efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

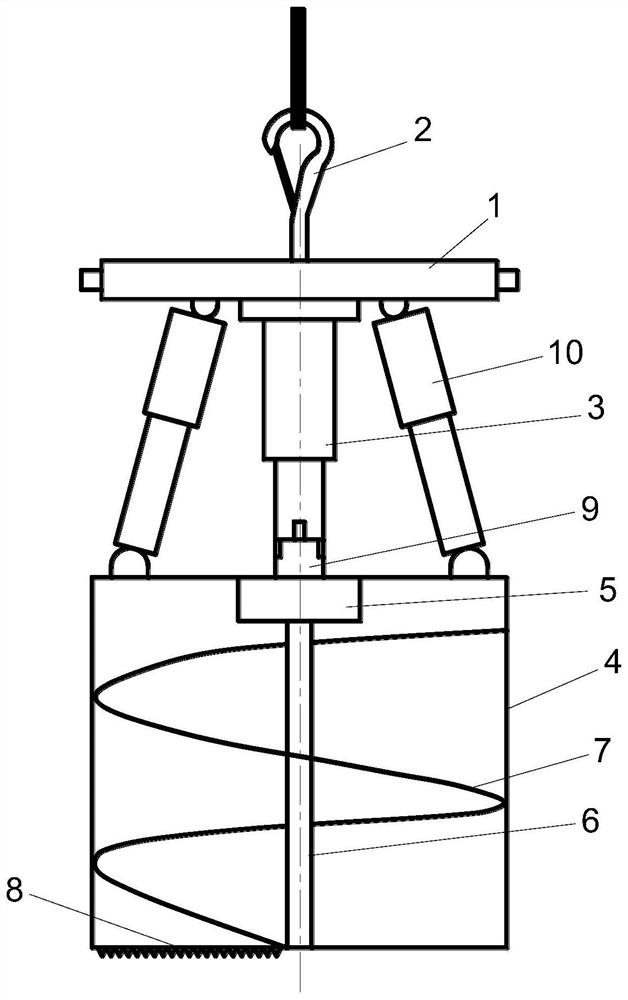

[0019] Such as figure 1 As shown, a debris collection device for drilling and blasting shaft excavation holes, comprising a main beam 1 of a positioning frame, the top of the main beam 1 of the positioning frame is fixedly connected with a hoisting hook 2, and the middle part of the bottom end of the main beam 1 of the positioning frame is connected There is a jacking cylinder 3, the bottom end of the jacking cylinder 3 is connected with a collection bucket 4, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com