Variable valve structure of internal combustion engine

A technology for internal combustion engines and valves, applied to internal combustion piston engines, combustion engines, non-mechanically actuated valves, etc., can solve problems such as engine burden, energy waves, and unstable gas distribution of the engine, so as to achieve stable gas distribution and reduce energy consumption wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

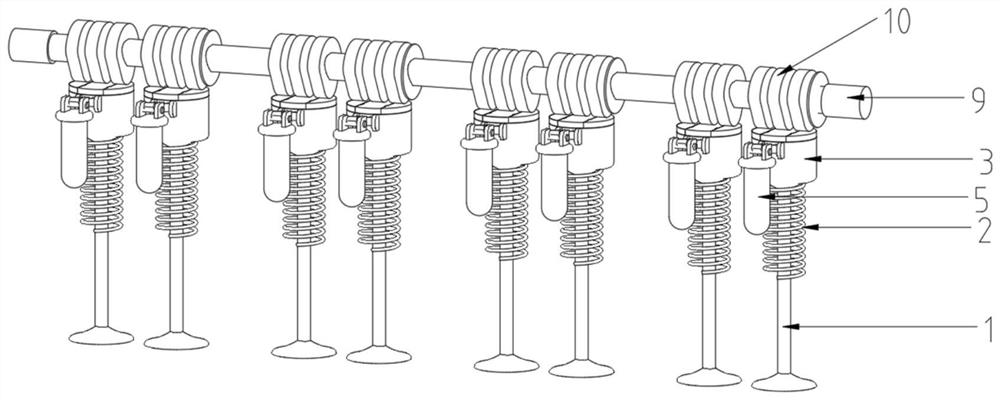

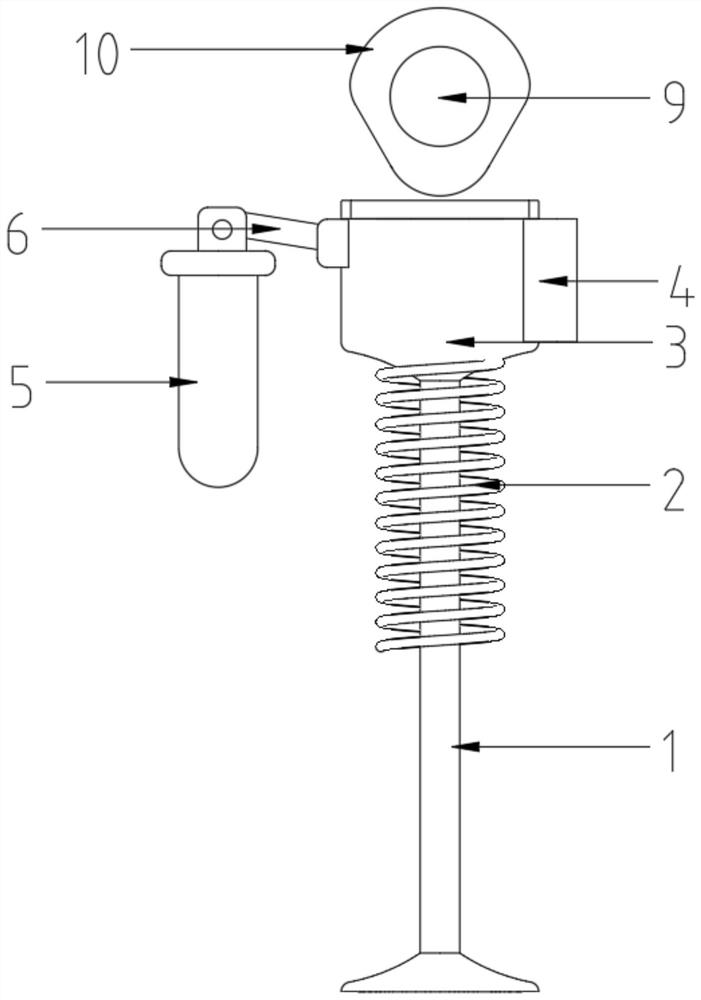

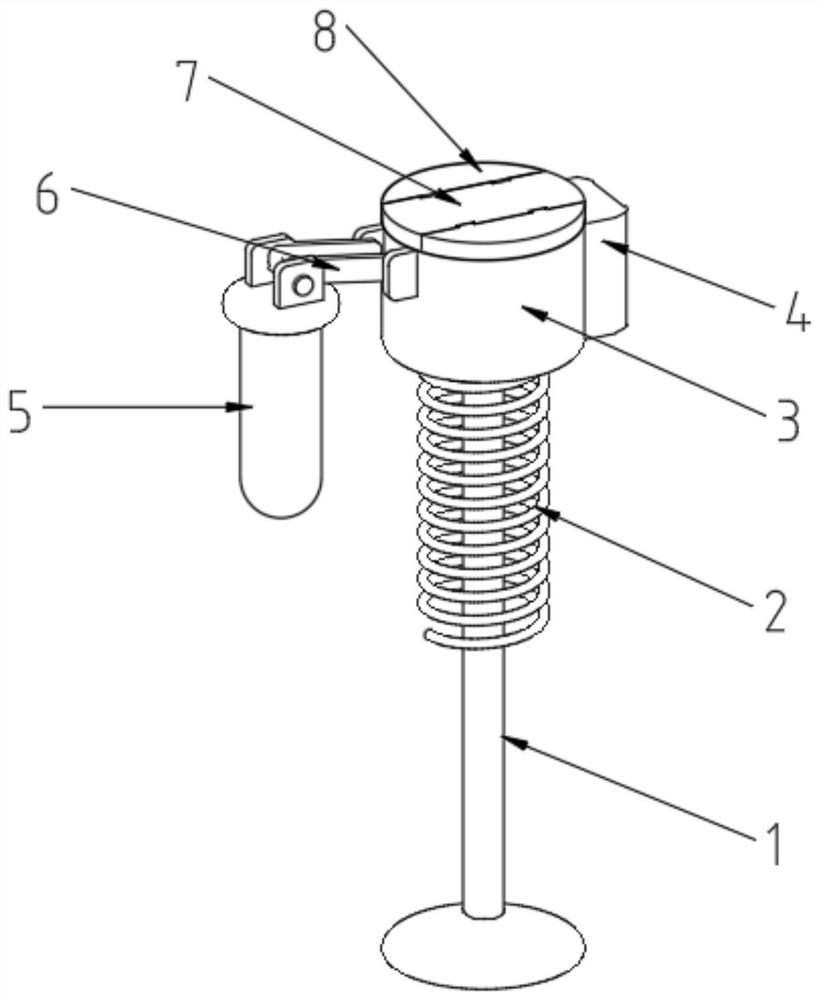

[0029] see Figure 1~5 , in an embodiment of the present invention, a variable valve structure of an internal combustion engine includes a valve assembly, a spring 2, a connecting head 3 and a first rotating shaft 9, the valve assembly is provided with several groups, and the number of each group of valve assemblies is set to two , the first rotating shaft 9 is provided with a number of cam groups, the first rotating shaft 9 is connected to the frame of the internal combustion engine in rotation, and each group of cam groups is provided with six first cams 10, the cam group is located above the valve assembly, the cam group and the valve The components correspond to each other, each set of cam sets corresponds to two sets of valve assemblies, and every three first cams 10 in the cam sets correspond to one set of valve assemblies, and the valve assemblies include a valve stem 1, a spring 2, a connector 3, a control box 4 and Hydraulic tappet 5, the lower end of the valve stem 1...

Embodiment 2

[0036] see Image 6 , 7 , 8, the difference in connection with the basis of Embodiment 1 is that the first rotating shaft 9 is covered with a number of rocker arms 103, the number of rocker arms 103 is the same as the number of valve assemblies, and the number of rocker arms 103 and valve assemblies are one by one Correspondingly, the rocker arm 103 is rotationally connected with the first rotating shaft 9, one end of the rocker arm 103 is in contact with the connector 3, and the other end is rotationally connected with a push rod 104, and the end of the push rod 104 away from the rocker arm 103 is provided with an adjustment rod 105, the second The left side of the first rotating shaft 9 is provided with a second rotating shaft 101, the second rotating shaft 101 is rotationally connected with the internal combustion engine frame, the second rotating shaft 101 is provided with a plurality of second cams 102, and the inside of the adjusting rod 105 is provided with a first adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com