High-strength aluminum alloy extruded material having excellent surface qualities

A high-strength, aluminum alloy technology, applied in the field of high-strength aluminum alloy extrusion materials, can solve the problems of insufficient strength and reduced surface quality, and achieve the effect of excellent surface quality and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

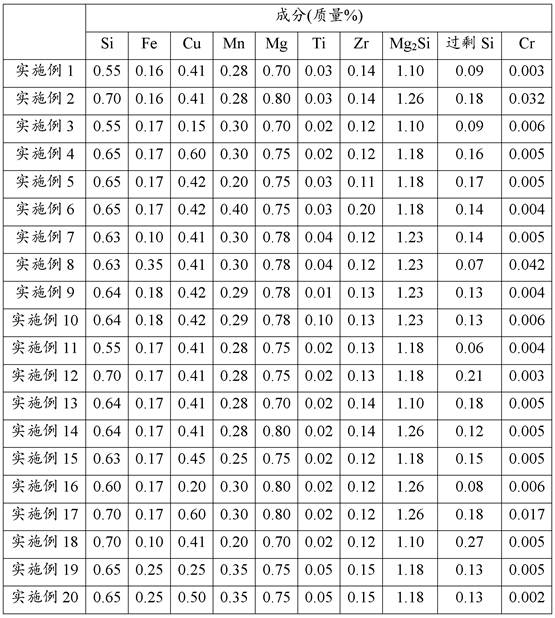

[0088] Hereinafter, although an Example is shown and this invention is demonstrated in more detail, this invention is not limited to these Examples.

[0089] According to the semi-continuous casting method, an aluminum alloy ingot with a diameter of 230 mm having the composition shown in Table 1 and Table 2 was produced, and after homogenizing the obtained ingot at 540° C. for 4 hours, it was taken out from the furnace. Forced air cooling with fans. These billets for extrusion are heated to 510°C in an induction heating furnace for hot extrusion, and extrusion processing is performed on flat plates with a width of 150 mm and a wall thickness of 2 mm and round tubes with an outer diameter of 70 mm and a wall thickness of 2 mm. After that, it is produced by rapid cooling based on water cooling immediately.

[0090] The obtained aluminum alloy extruded material was aged at 190° C. for 5 hours.

[0091] "Determination of Tensile Yield Strength"

[0092] According to JISZ2241, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com