Particles for heating cigarettes and preparation method thereof

A technology for granules and cigarettes, which is applied in the field of granules for heating cigarettes and its preparation. It can solve the problems of instability, moisture absorption and aroma release of granules, and achieve the effects of accelerating the heating process, improving heat conduction efficiency, and prolonging the fragrance retention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

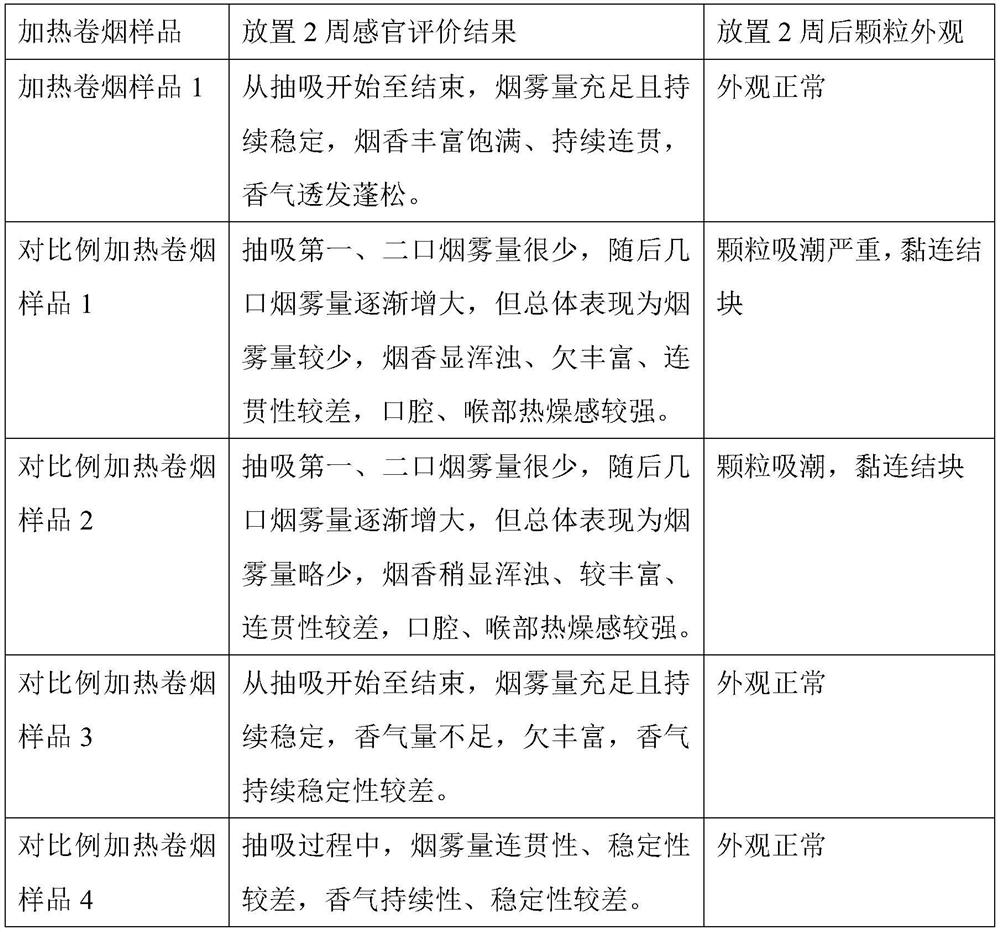

Examples

Embodiment 1

[0055] A method for preparing particles for heating cigarettes, comprising the following steps:

[0056] Step 1, raw material pretreatment, the selected leaf group raw material is roasted to remove miscellaneous gas, and the moisture content is adjusted to 6wt% at the same time.

[0057] Step 2, crushing and grading the raw material, the tobacco leaf raw material is first crushed, and the raw material after the primary crushing is then ultrafinely crushed, and the outlet of the pulverizer is set at an 80-mesh mesh to obtain the crushed raw material. The pulverized raw materials are classified to separate 80-150 mesh powder, 150-200 mesh powder and powder with particle size less than 200 mesh.

[0058] Step 3, raw material primary treatment. Mix the tobacco powder with a particle size of 150-200 mesh and the tobacco powder with a particle size of less than 200 mesh at a mass ratio of 10:1. After the mixed powder is mixed evenly, add flavor and smoke agent. The smoke agent is ...

Embodiment 2

[0071] A method for preparing particles for heating cigarettes, comprising the following steps:

[0072] Step 1, raw material pretreatment, the selected leaf group raw material is roasted to remove miscellaneous gas, and the water content is adjusted to 12wt% at the same time.

[0073] Step 2, crushing and grading the raw material, the tobacco leaf raw material is first crushed, and the raw material after the primary crushing is then ultrafinely crushed, and the outlet of the pulverizer is set at an 80-mesh mesh to obtain the crushed raw material. The pulverized raw materials are classified to separate 80-150 mesh tobacco powder, 150-200 mesh tobacco powder and tobacco powder with particle size less than 200 mesh.

[0074] Step 3, raw material primary treatment. Mix the tobacco powder with a particle size of 150-200 mesh and the tobacco powder with a particle size of less than 200 mesh, the mixing mass ratio is 20:1, and after the mixed powder is mixed, add flavor and smoke a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com