Preparation device of microcrystalline cellulose pellet core

A technology for microcrystalline cellulose pills and a preparation device, which is applied in the field of medicine, can solve the problems of lengthy process, difficult volume control, cracking of rolling pills, etc., and achieves the effect of eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

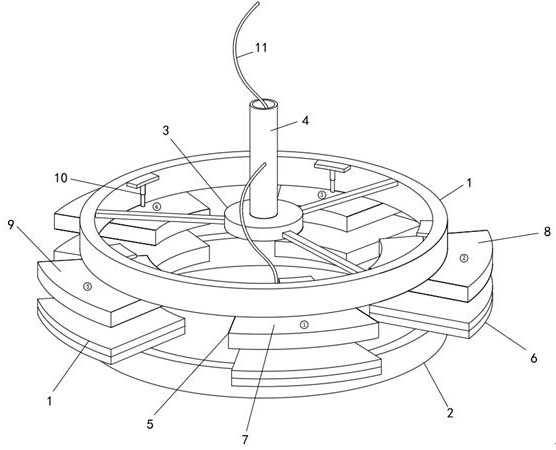

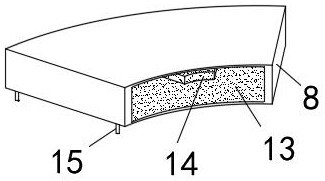

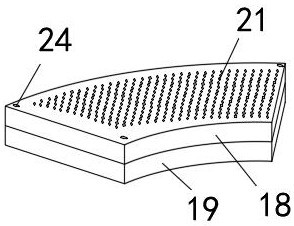

[0030] like Figure 1-8 , The apparatus for preparing a microcrystalline cellulose pellet cores, comprising a stationary ring and a rotational ring 2, ring 1 is rotatably disposed above the fixed ring 2, the rotating rings 1 can be rotated above the fixed ring 2, and is fixed in a particular height position, only the rotation cycle, is connected to a rotatable ring on the holder 3, the holder 3 for the rotation wheel 1 is fixed, and the rotation of the drive wheel 1 is rotated, the holder 3 has a plurality claw , respectively, the fixed support ring and the inner ring 1 is rotated, the inner holder 3 comprises a hollow tube 4, hollow tube 4 not only as a major stress points, as well as a rotation center, hollow tube 4 may be means for receiving, on a plurality of lines or pipes rest integration device housing.

[0031] 1 may be rotatable ring is rotated by the holder 3 to perform the operation cycle, respectively, the rotational ring 1 and the fixed ring 5 and the injection mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com