High-speed fermentation organic waste processor

A technology of organic waste and processing machine, which is applied in the field of rapid fermentation of organic waste, can solve the problems of uneven fermentation, cost increase, unreasonable blade setting, etc., and achieve the goal of increasing fermentation rate, reducing equipment cost and ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

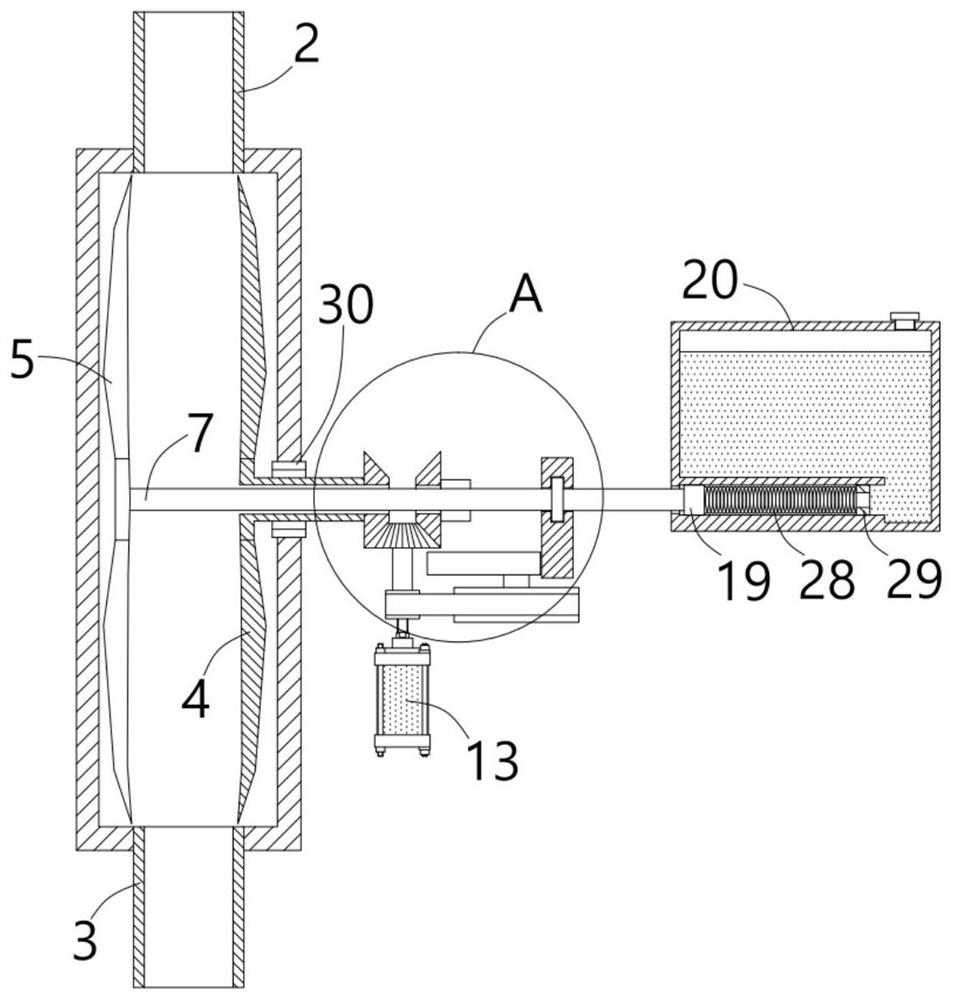

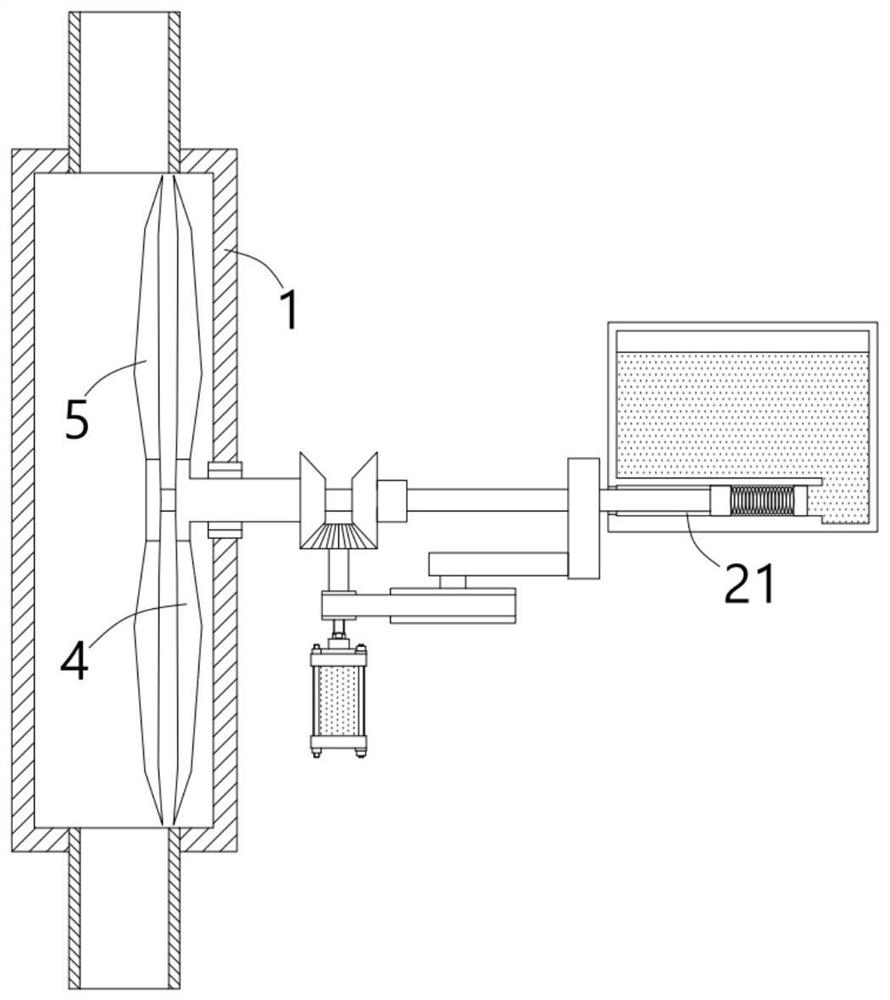

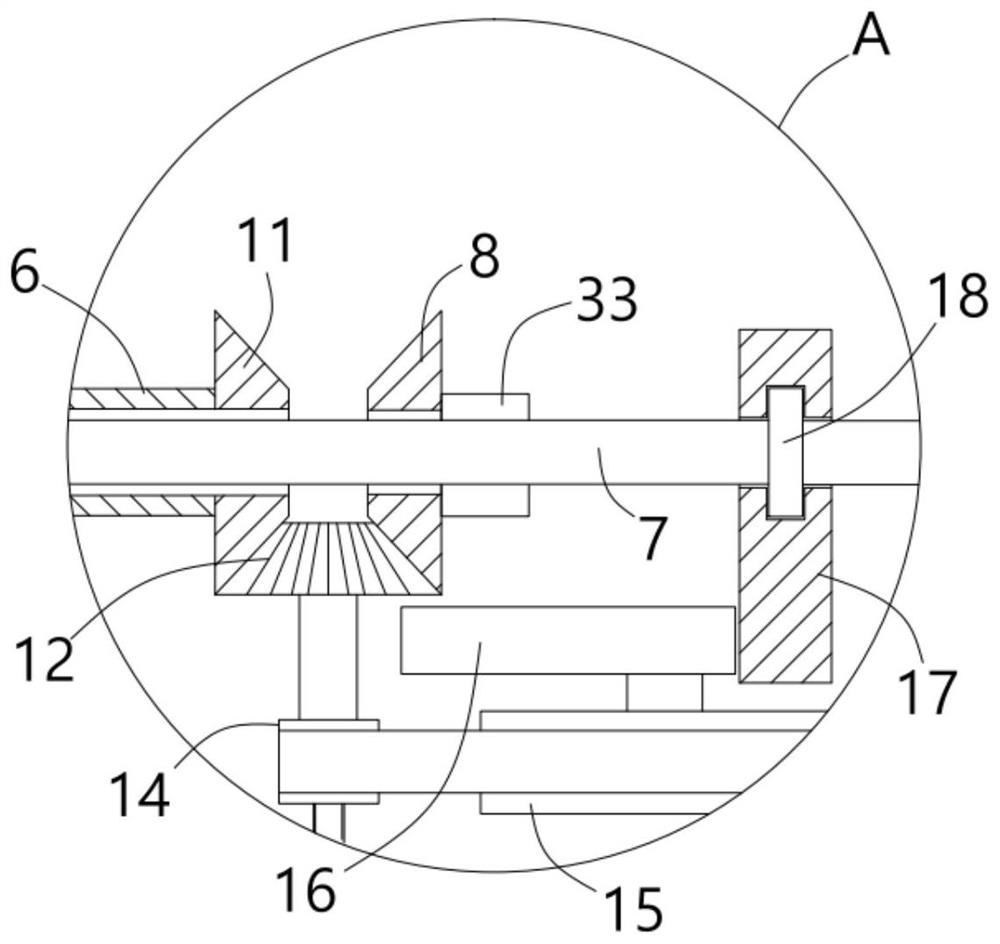

[0029] see Figure 1-8 , the present invention provides a technical solution:

[0030] A high-speed fermented organic waste processing machine, comprising a mixing and crushing cylinder 1 and its upper and lower feed channels 2 and discharge channels 3 respectively, and the mixing and crushing tube 1 is respectively provided with coaxial and counter-rotating positioning crushing wheels 4 and the mobile crushing wheel 5, the wheel shafts of the positioning crushing wheel 4 and the mobile crushing wheel 5 are respectively fixedly equipped with a wheel shaft sleeve 6 and a wheel shaft 7, and the wheel shaft 7 is movably inserted in the wheel shaft sleeve 6, and the movable sleeve on the wheel shaft 7 is provided with Sliding helical gear 8, the sliding helical gear 8 is provided with a pin shaft groove 9, the pin shaft groove 9 and the pin shaft 10 are movably matched, the pin shaft 10 is fixedly installed on the wheel shaft 7, and the wheel shaft sleeve 6 is fixed on the side aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com