Rotating disc type numerical control sand blasting and shot blasting machine for large workpieces

A large workpiece, turntable technology, used in abrasive jet machine tools, used abrasive treatment devices, spray guns, etc. The effect of good treatment effect, clean surface and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

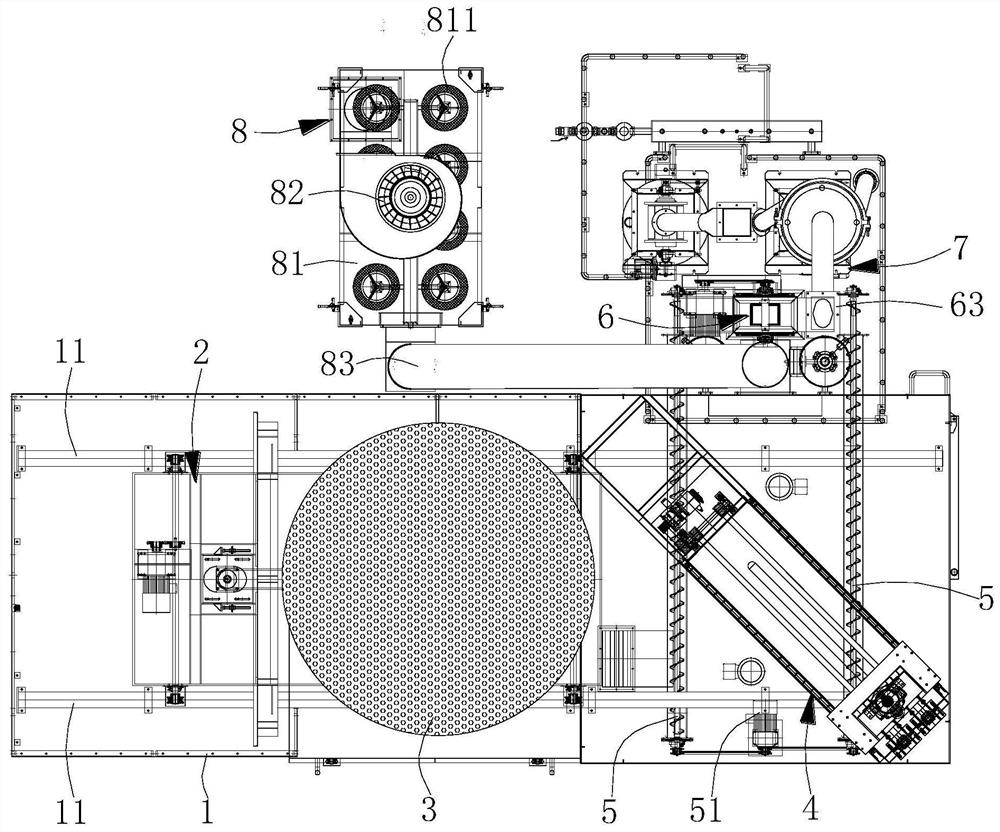

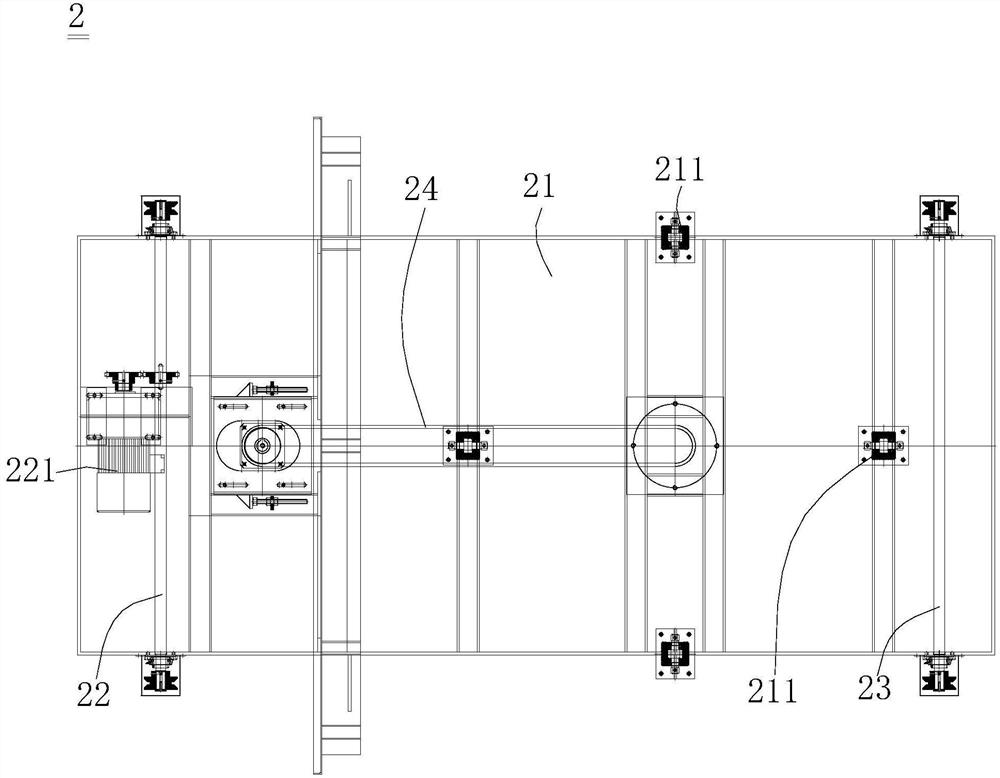

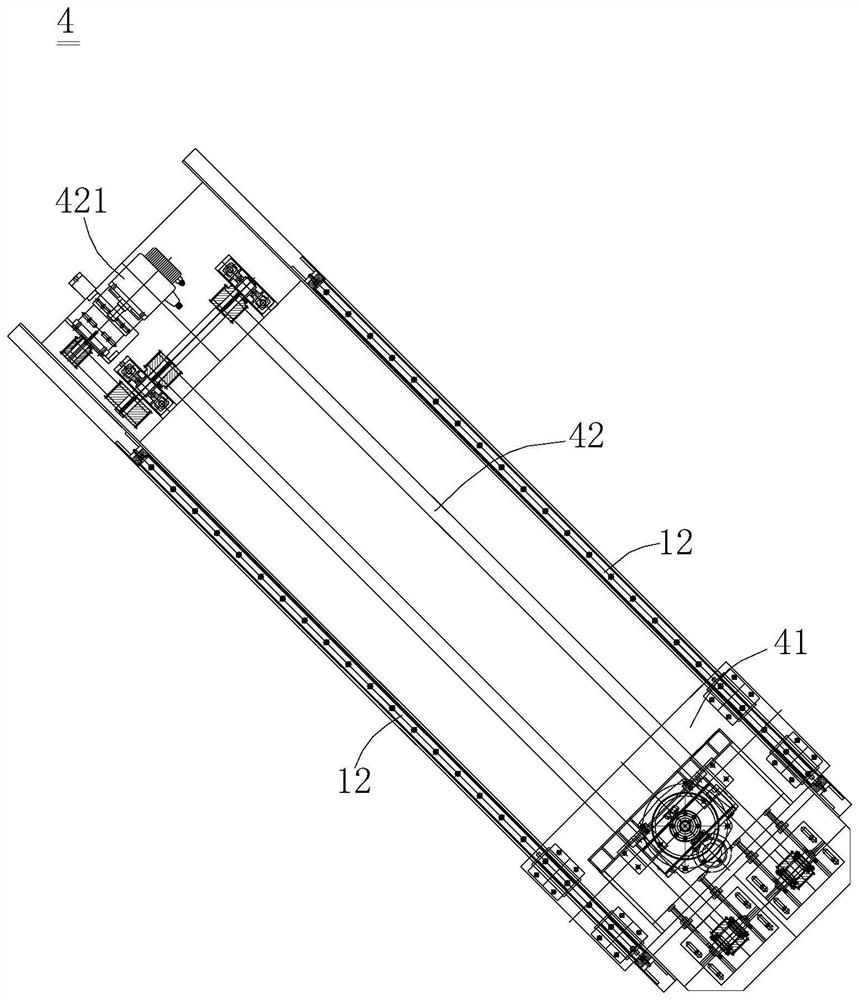

[0030] refer to Figure 1 to Figure 9 , a turntable type CNC sand blasting machine for large workpieces, including a frame 1, a turntable 3, an electric trolley 2, a spray gun moving drive mechanism 4, a plurality of spray guns, a conveying mechanism, and a lifting mechanism 6. A shot blasting device 7 and a dust removal device 8. The frame 1 is provided with a sandblasting chamber and a sand collection chamber in sequence from top to bottom. On the electric trolley 2, the electric trolley 2 can be horizontally moved to the sandblasting chamber on the working panel, so that the turntable 3 is located between the sandblasting chamber and the sand collecting chamber, and the spray gun moving driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com