High-purity trioxymethylene refining system and process

A technology of high-purity paraformaldehyde and refining system, which is applied in the field of high-purity paraformaldehyde refining system and technology, can solve the problems that the purity of paraformaldehyde is difficult to meet the demand, the effect of paraformaldehyde refining is limited, etc., and achieve repeated recycling , help to purify, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

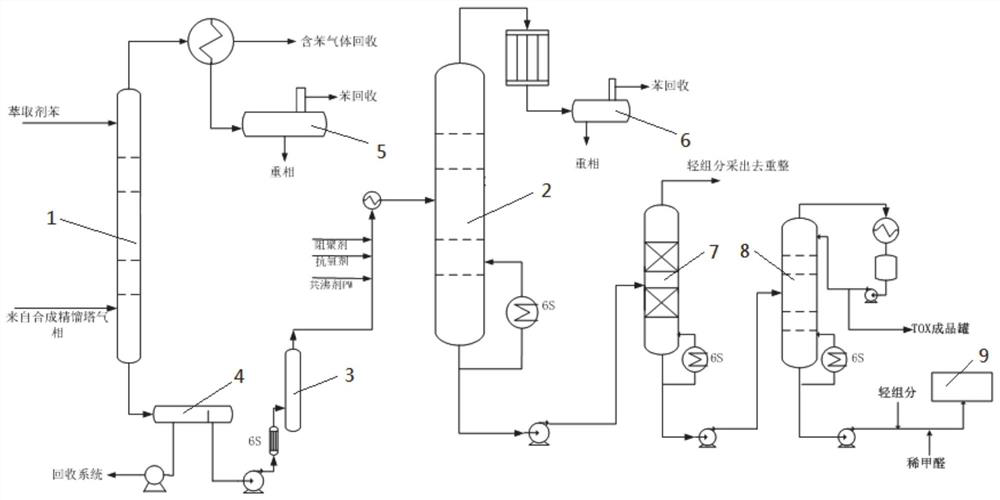

[0051] Such as figure 1 As shown, the present embodiment provides a high-purity paraformaldehyde refining system, comprising a gas-liquid extraction tower 1 and a benzene recovery tower 2, a water washing tower 3 is arranged between the gas-liquid extraction tower and the benzene recovery tower, and the inlet of the water washing tower 3 The first stratifier 4 is arranged at the place, and the paraformaldehyde crude gas first enters the gas-liquid extraction tower to extract with benzene, and the solution collected at the bottom of the tower is first separated from the heavy phase (dilute aldehyde aqueous solution) by the first stratifier 4, It is then passed into a water washing tower for water washing, and after dilute aldehyde impurities are further removed, the overflow liquid is collected from the top of the water washing tower and passed into a benzene recovery tower to separate benzene and paraformaldehyde.

[0052] Among them, the gas-liquid extraction tower 1 is equip...

Embodiment 2

[0059] The present embodiment provides a kind of technique that adopts the system in embodiment 1 to carry out paraformaldehyde refining, specifically:

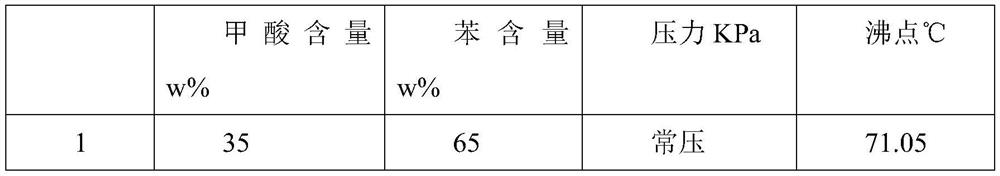

[0060] Firstly, pass the paraformaldehyde crude gas into the gas-liquid extraction tower, and under the condition of operating pressure of -15KPa and tower top operating temperature of 68°C, the extractant benzene is pressurized by the benzene reflux pump and sprayed down from the upper part of the tower , fully contact with crude paraformaldehyde gas to achieve efficient extraction of paraformaldehyde.

[0061] Then, collect the solution at the bottom of the gas-liquid extraction tower, first separate the heavy phase (dilute aldehyde aqueous solution) by the first stratifier 4, then pass into the water washing tower for washing, and the overflow liquid at the top of the water washing tower is imported into the benzene recovery tower, At the same time, TEA, IRG259 and desalted water are added to the benzene recovery tower to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com