Comprehensive recovery process of silver, lead, zinc and sulfur-containing bulk concentrate

A technology of mixing concentrate and zinc-sulfur, which is applied in the field of metallurgy, can solve the problems of low recovery rate of comprehensive utilization of resources, serious mutual inclusion of concentrate products, and inability to achieve high-efficiency separation, so as to reduce the dosage of chemicals and avoid metal loss , Increase the effect of monomer dissociation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

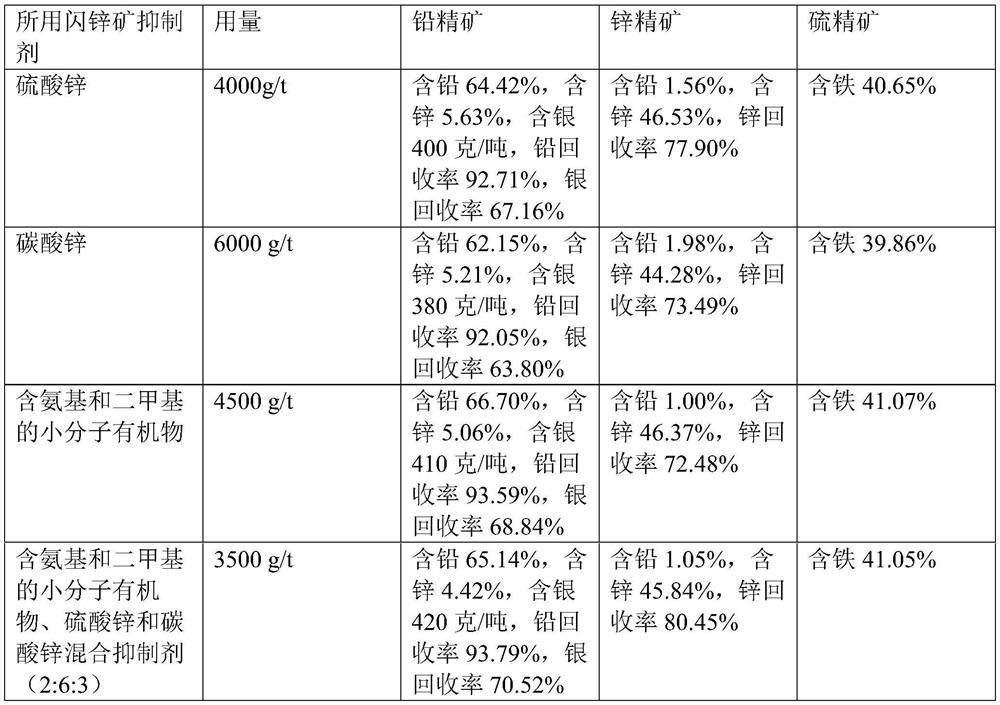

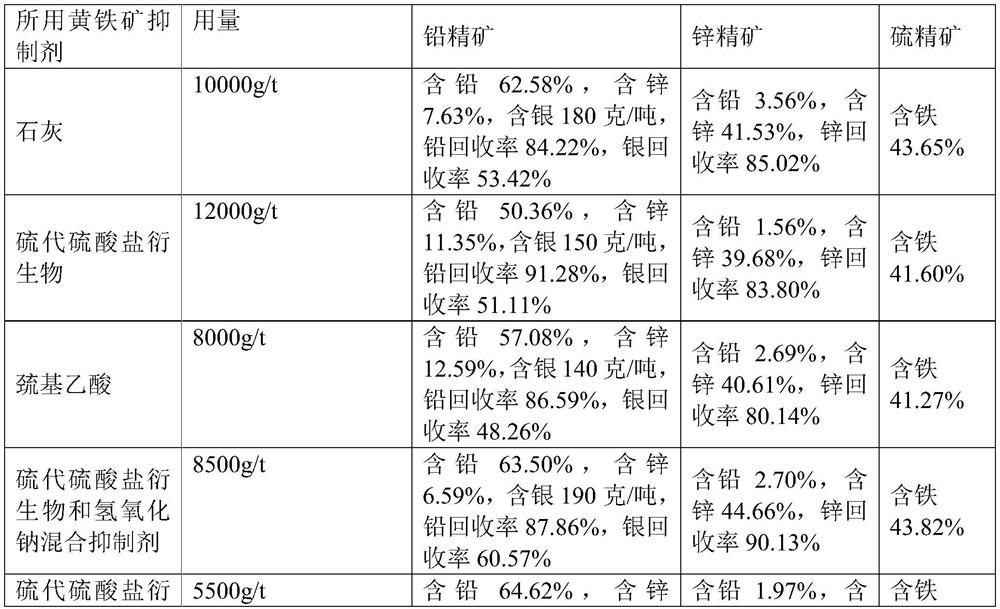

[0060] A concentrator in Huize, Yunnan, contains 10.67% lead, 7.89% zinc, and 32.59% iron. The main metal minerals are galena, sphalerite and pyrite, accompanied by 91 grams / ton of silver. Xanthate obtained the silver-lead-zinc-sulfur mixed concentrate, and the above-mentioned ore sample was processed through the following process steps:

[0061] A. Drug removal: Concentrate the mixed concentrate containing silver, lead, zinc and sulfur to a concentration of 60-65%, and remove dixanthate. Add 6000 g / ton of sphalerite inhibitor and pyrite inhibitor lime, and then feed it into the ball mill for grinding, scrubbing, and drug removal;

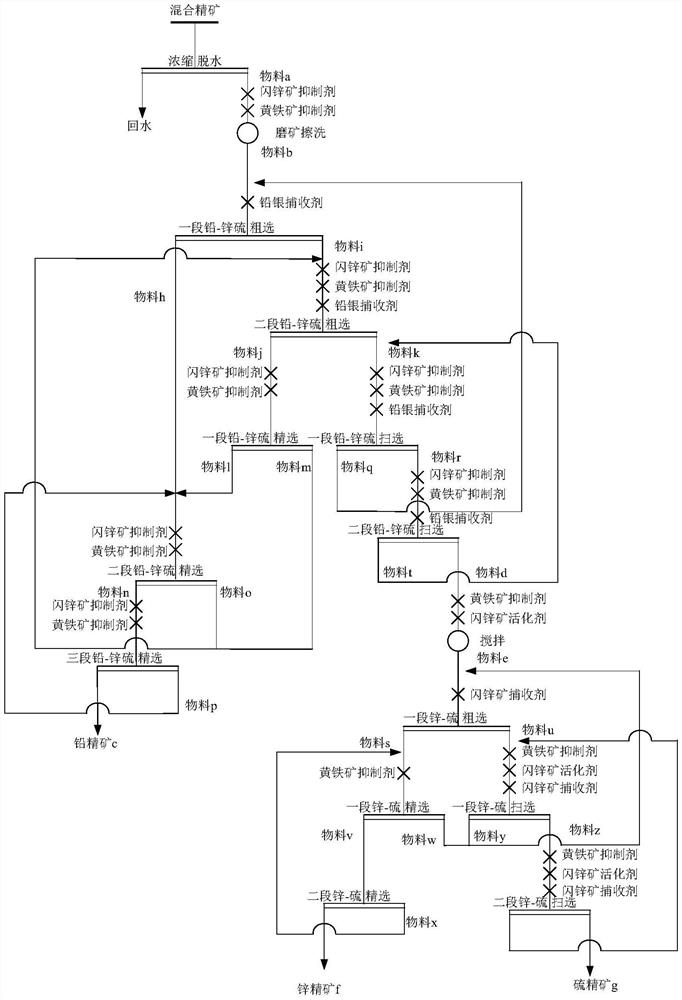

[0062] B. Lead-zinc-sulfur separation flotation: Add 50 g / ton of lead-silver collector to the finely ground pulp, and feed it into the flotation machine for two-stage roughing, two-stage sweeping, and three-stage selected lead -Zinc-sulfur separation flotation. The first-stage lead-zinc-sulfur roughing foam (material h) and material l are combine...

Embodiment 2

[0068] A dressing plant in Lancang, Yunnan, containing 3.88% lead, 6.16% zinc, 15.09% iron, and 43 g / t silver. The main metal minerals are sphalerite, galena and pyrite, and the embedded particle size is relatively coarse , the buoyancy is very good, the above-mentioned ore sample is processed through the following process steps:

[0069] A. Drug removal: Concentrate the mixed concentrate containing silver, lead, zinc and sulfur to a concentration of 65-70%, add 8000 g / t of sphalerite inhibitor zinc sulfate and pyrite inhibitor, and then feed it into a ball mill for grinding Scrub off medicine;

[0070] B. Lead-zinc-sulfur separation flotation: Add 60 g / ton of lead-silver collector isopropyl xanthate to the ground pulp, and feed it into the flotation machine for two-stage roughing, two-stage sweeping and three-stage selection The lead-zinc sulfur separation flotation. The first-stage lead-zinc-sulfur roughing concentrate (material h) and material l are combined for the secon...

Embodiment 3

[0077] A dressing plant in Lancang, Yunnan, containing 3.88% lead, 6.16% zinc, 15.09% iron, and 43 g / t silver. The main metal minerals are sphalerite, galena and pyrite, and the embedded particle size is relatively coarse , the buoyancy is very good, the above-mentioned ore sample is processed through the following process steps:

[0078] A. Drug removal: Concentrate the mixed concentrate containing silver, lead, zinc and sulfur to a concentration of 65-70%, add 6000 g / t of sphalerite mixed inhibitor and 2000 g / t of pyrite mixed inhibitor, and then feed it into the ball mill , carry out grinding, scrubbing, and drug removal (the sphalerite mixed inhibitor described in this embodiment and the following examples all refers to the small molecule organic matter containing amino and dimethyl, zinc sulfate and zinc carbonate mixed inhibitor (2:6 : 3), described pyrite mixed inhibitor all refers to thiosulfate derivative, thioglycolic acid and sodium hydroxide mixed inhibitor (6:3:3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com