A kind of maca extract sugar removal process

A technology of maca extract and maca extract liquid is applied in the directions of food ingredients containing natural extracts, food science, plant raw materials, etc. and other problems, to achieve the effect of low cost, simple equipment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

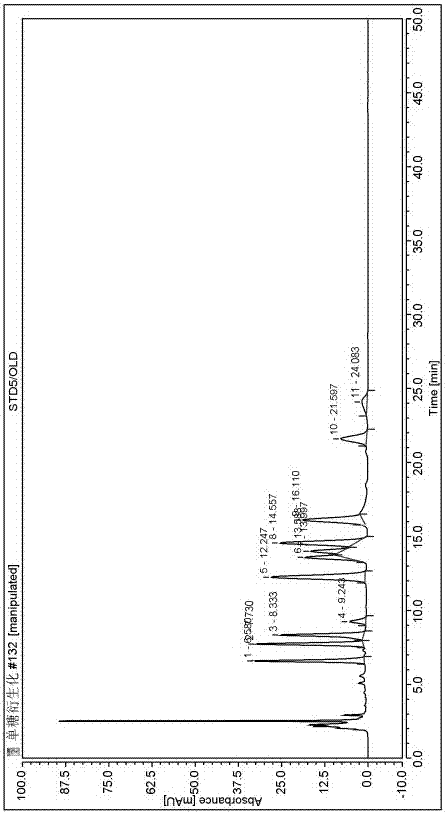

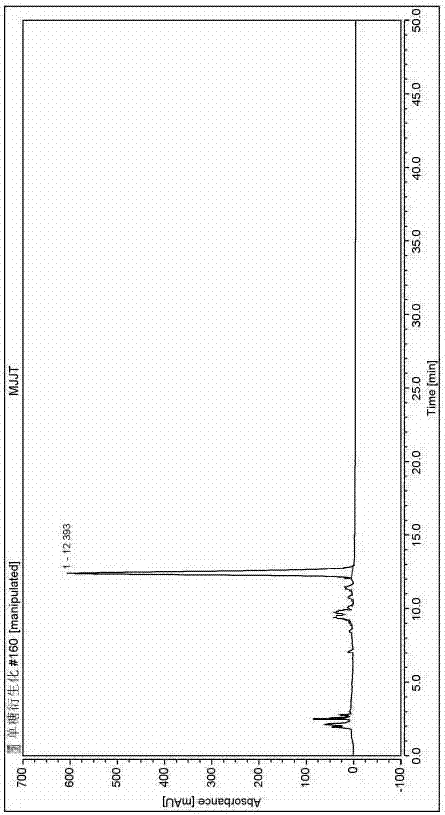

Image

Examples

Embodiment 1

[0026] The process for removing sugar from maca extract in this embodiment includes the following steps.

[0027] (1) Concentrate the maca extract in a vacuum concentrator at a temperature of 35-50°C and a pressure of 5-12Kpa to recover the extractant. The maca extract in the present invention can be ethanol extract or water-alcohol mixed extract of maca, and the water-alcohol mixed extract of maca refers to the extract obtained by extracting maca with ethanol aqueous solution. The maca extract is recovered in a low-temperature and low-pressure environment to obtain a concentrated extract, which contains macaene, macamide, and glucosinolate functional components, as well as a large amount of sugar.

[0028] (2) Dissolve the concentrated extract obtained in step (1) in edible ethanol, the weight of the used edible ethanol is 15 to 25 times the weight of the concentrated extract, stir evenly, it is a light yellow clear solution, and then rotate in vacuum In an evaporator, the t...

Embodiment 2

[0036] The process for removing sugar from maca extract in this embodiment includes the following steps.

[0037] (1) Get 100Kg maca dried slices, crush to 200 orders, pour into the ultrasonic extraction kettle, add 500Kg of edible ethanol with a volume percentage of 80%, ultrasonically extract 3 times, combine the extracts, obtain 1600Kg maca ethanol water altogether Mix the extracts.

[0038] (2) Pour the maca ethanol water mixed extract into a continuous rotary evaporator, concentrate and recover ethanol at a temperature of 35°C and a vacuum of 10Kpa pressure, and then concentrate and recover water at a temperature of 40°C and a vacuum of 8Kpa pressure , Obtain 22Kg to extract concentrated extract.

[0039] (3) Dissolve the concentrated extract in 440Kg of edible ethanol, stir evenly to form a light yellow clear solution, then place the dissolved edible ethanol solution in a continuous vacuum rotary evaporator at a temperature of 35°C and a pressure of 12Kpa , the volume ...

Embodiment 3

[0047] The process for removing sugar from maca extract in this embodiment includes the following steps.

[0048] (1) Get 500Kg of maca dried powder, pour it into an ultrasonic extraction kettle, add 3000Kg of edible ethanol, ultrasonically extract 3 times, and combine the extracts to obtain a total of 9500Kg of maca ethanol extract.

[0049] (2) Pour the maca ethanol extract into a continuous rotary evaporator, concentrate and recover ethanol at a temperature of 35° C. and a vacuum of 10 Kpa pressure, and concentrate the volume to 1000 liters.

[0050] (3) 1000L maca ethanol solution was placed in an interlayer crystallization tank, and the interlayer of the crystallization tank was passed through a cooling liquid at 5°C, and left to stand at low temperature for 48 hours.

[0051] (4) Adjust the temperature of the cooling liquid of the crystallization tank to 0° C. After stabilization, stir the maca ethanol solution at a constant speed at a speed of 60 rpm for 30 minutes. Whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com