Hydrogenated linear polydiene copolymers as base stock or lubricant additives for lubricant compositions

A technology of linear copolymers and hydrogenated copolymers, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as poor traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0148] Experimental part

[0149] Hereinafter, the present invention is illustrated in further detail with reference to Examples and Comparative Examples, without intending to limit the scope of the present invention.

[0150] abbreviation

[0151] PMMA Polyalkyl(meth)acrylate

[0152] MMA methacrylic acid C 1 - Alkyl ester = methyl methacrylate

[0153] BMA methacrylic acid C 4 - Alkyl ester = n-butyl methacrylate

[0154] LMA methacrylic acid C 12 / 14 - Alkyl ester = lauryl methacrylate

[0155] KRL Kegelrollenlager (= tapered roller bearing)

[0156] KV 40 Kinematic viscosity at 40°C measured according to ASTM D445

[0157] KV 100 Kinematic viscosity at 100°C measured according to ASTM D445

[0158] m n Number average molecular weight

[0159] m w Weight average molecular weight

[0160] NB3030 Nexbase , a Group III base oil from Neste with a KV of 3.0 cSt 100

[0161] NB3043 Nexbase , a Group III base oil from Neste with a KV of 4.3 cSt 100

[0...

Embodiment

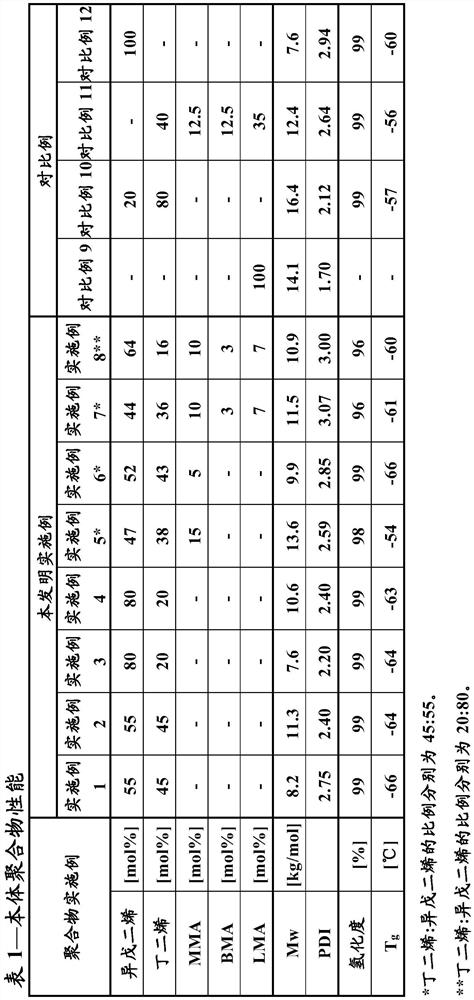

[0175] Examples (as also shown in Table 1 below)

[0176] Examples 1 to 4 of the invention are based on monomer compositions of butadiene and isoprene.

[0177] Inventive Examples 5 and 6 are based on monomer compositions of butadiene, isoprene and methyl (meth)acrylate.

[0178] Inventive Examples 7 and 8 are based on monomer compositions of butadiene, isoprene, methyl (meth)acrylate, butyl (meth)acrylate and lauryl (meth)acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com