Preparation method of in-situ regenerated titanium nitride steel-based roller

A titanium nitride steel-based, in-situ regeneration technology, applied in the field of roll manufacturing in the iron and steel metallurgy industry, can solve the problem of solid ceramic particles floating on the surface of molten steel, easy to fall off, low surface activity of TiN ceramic particles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

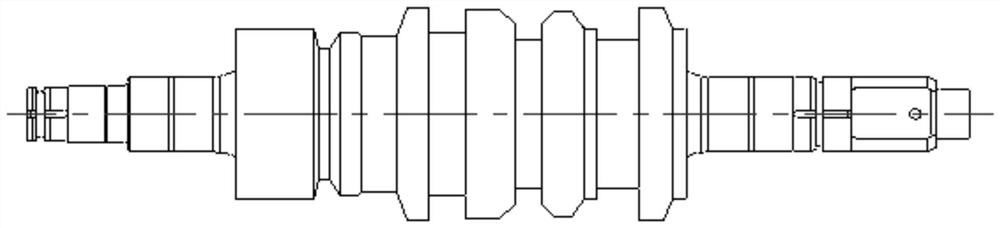

[0035] Such as figure 1 As shown, it is an alloy cast steel BD roll prepared by in-situ regenerated titanium nitride steel-based roll, which is manufactured by the static integral top casting method and is suitable for single-stand BD or double-stand BD1. The preparation steps are:

[0036] (1) Molding: According to the product specification and process of production, the bottom box for the cast lower roll neck, the cold mold for the roll body, and the upper box and riser for the upper roll neck are respectively molded; baked and dried; and The bottom box, the cold box, the top box, and the riser box are connected in sequence to form (combined box);

[0037] (2) Smelting: Put all raw materials into an intermediate frequency furnace for smelting, remove slag, and then roughly adjust the chemical composition of the original steel-based alloy melt according to the middle and lower limits of the following range: C0.6-0.75%, Si0.4-0.8 %, Mn0.5-1.2%, Cr0.8-1.5%, Ni0.2-1.2%, Mo0.2-...

Embodiment 2

[0045] Such as figure 1 As shown, it is a kind of graphite semi-steel BD roll prepared by the static integral top casting method provided by the present invention, which is suitable for double-frame BD2 and in-situ regeneration of titanium nitride steel-based roll raw materials. The specific preparation steps are as follows: :

[0046] (1) molding: with embodiment 1;

[0047] (2) Smelting: The difference between this embodiment and step (2) of Embodiment 1 is that the chemical composition of the original steel-based alloy melt is adjusted to: C1.2-1.4%, Si0.4-1.0 %, Mn0.5-1.2%, Cr0.8-1.5%, Ni0.5-1.5%, Mo0.2-0.8%, V0.01-0.2%, Ti0.02-0.05%, Al0.02-0.03% , [N]0.02-0.04%, the rest is Fe steel-based alloy materials, in addition, P, S, [O] are harmful elements usually P≤0.03%, S≤0.025%, after deoxidation [O]≤0.0015% (first Roughly adjust the chemical composition of the alloy according to the lower limit of the process in the intermediate frequency furnace, including adjusting Ti ...

Embodiment 3

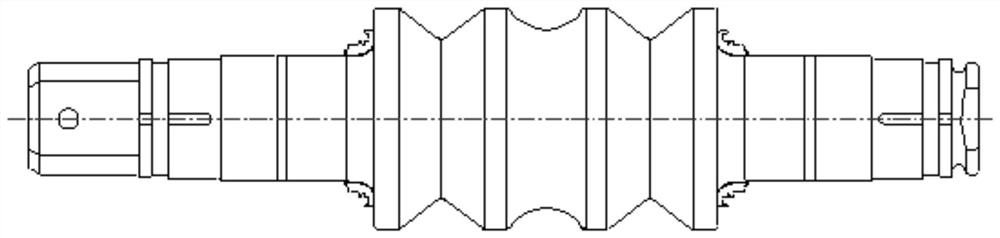

[0056] Such as image 3 As shown, it is a graphite semi-steel billet continuous rolling roll prepared by in-situ regenerated titanium nitride steel-based roll raw material provided by the invention using a static integral top casting method, and its specific preparation steps are:

[0057] The difference between this embodiment and Example 2 is that the contents of each component of the raw material are: C1.4-1.8%, Si0.4-1.0% (0.6-1.5)% before inoculation, Mn0.5-1.2%, Cr0 .8-1.5%, Ni0.5-1.5%, Mo0.2-0.8%, V0.01-0.2%, Ti0.02-0.05%, Al0.02-0.03%, [N]0.03-0.04%, the rest It is a steel-based alloy material of Fe. In addition, P and S are usually P≤0.03 and S≤0.025 as harmful elements. Tuning + fine-tuning, do not use the refining furnace for smelting, but use the refining bag to blow nitrogen. The difference between the refining furnace and the refining bag is that the furnace has a heating function, and the bag only has the function of blowing without heating. All the refining ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com