Cable-stayed bridge anti-seismic steel inclined strut and construction method thereof

A construction method and technology for cable-stayed bridges, applied to cable-stayed bridges, bridges, bridge materials, etc., can solve problems such as hollow reinforced concrete, smaller usable area, and difficult construction, so as to speed up construction progress, prolong life, and improve The effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

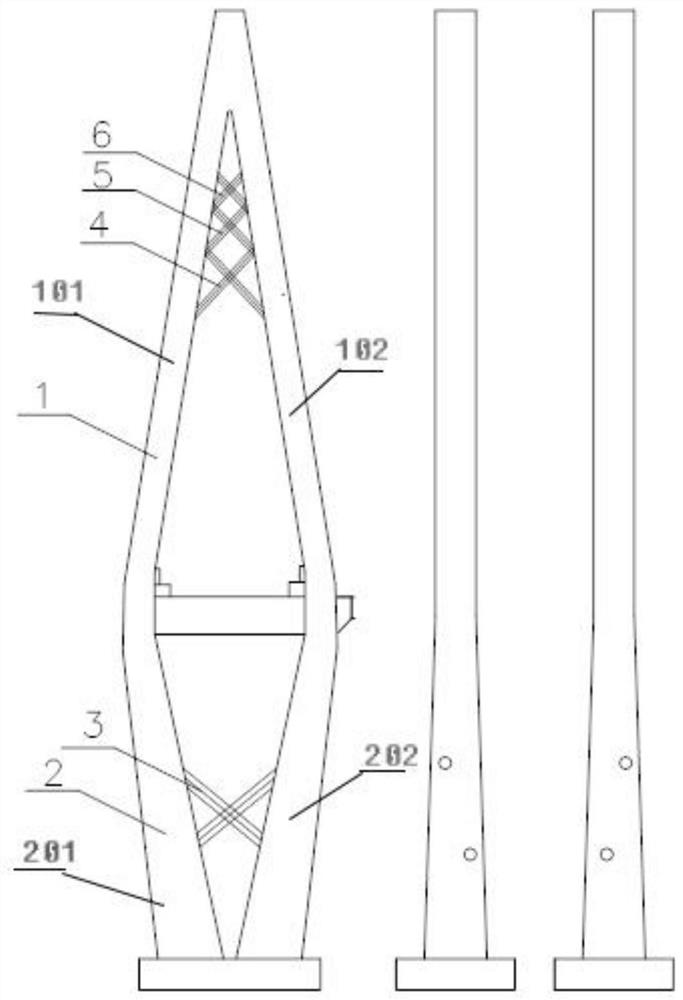

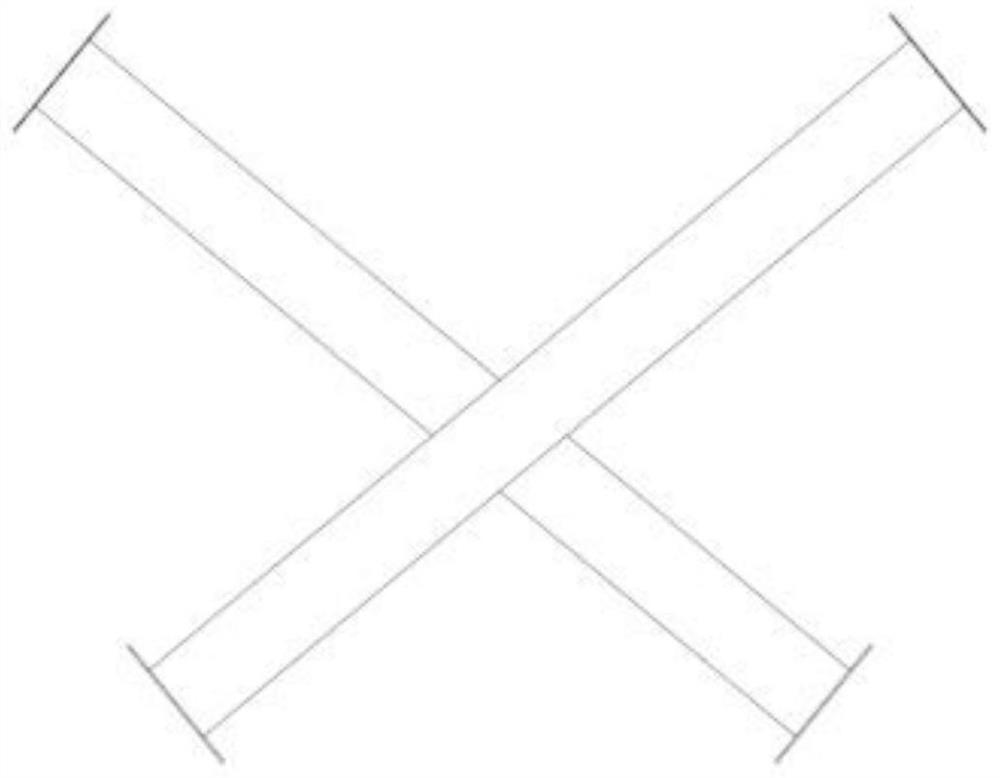

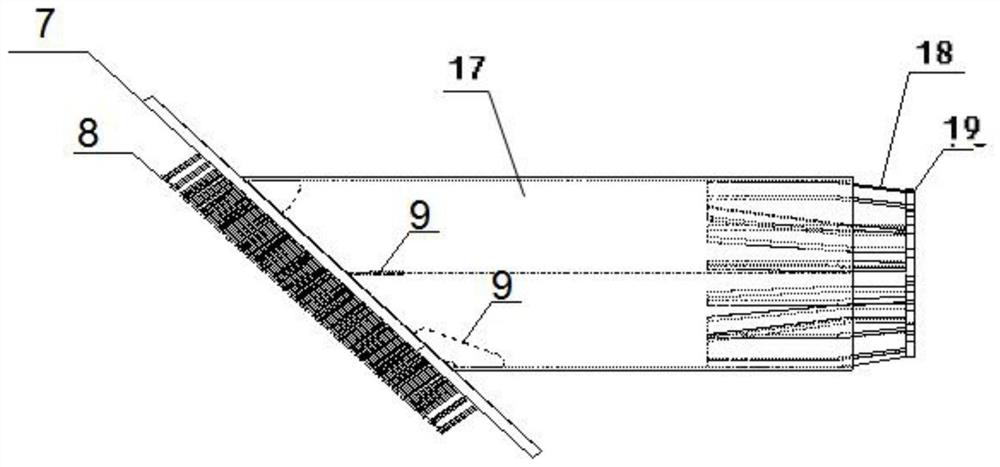

[0059] An anti-seismic steel diagonal brace of a cable-stayed bridge, such as Figure 1-Figure 12 As shown, it includes the main tower of the cable-stayed bridge and steel braces, and is characterized in that: the main tower of the cable-stayed bridge includes an upper tower column 1 and a lower tower column 2, and the upper tower column 1 includes the first left tower limb 101 and The first right tower limb 102, the lower tower column 2 includes a second left tower limb 201 and a second right tower limb 202, and a second steel rod is installed between the first left tower limb 101 and the first right tower limb 102. The diagonal brace 4, the third steel diagonal brace 5 and the fourth steel diagonal brace 6, the first steel diagonal brace 3 is installed between the second left tower limb 201 and the second right tower limb 202; the first steel diagonal brace The brace 3 and the second steel brace 4 are insertion anchored steel braces, and the third steel brace 5 and the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com