Anti-seepage drainage structure and construction method thereof

A drainage structure, anti-penetration technology, applied in infrastructure engineering, construction, liquid/vacuum measurement for liquid tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

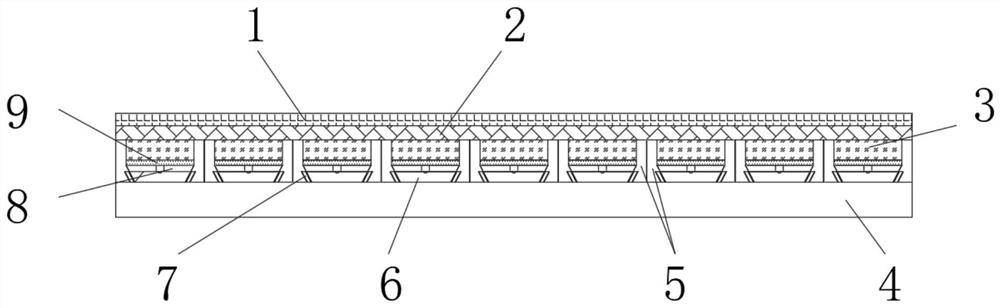

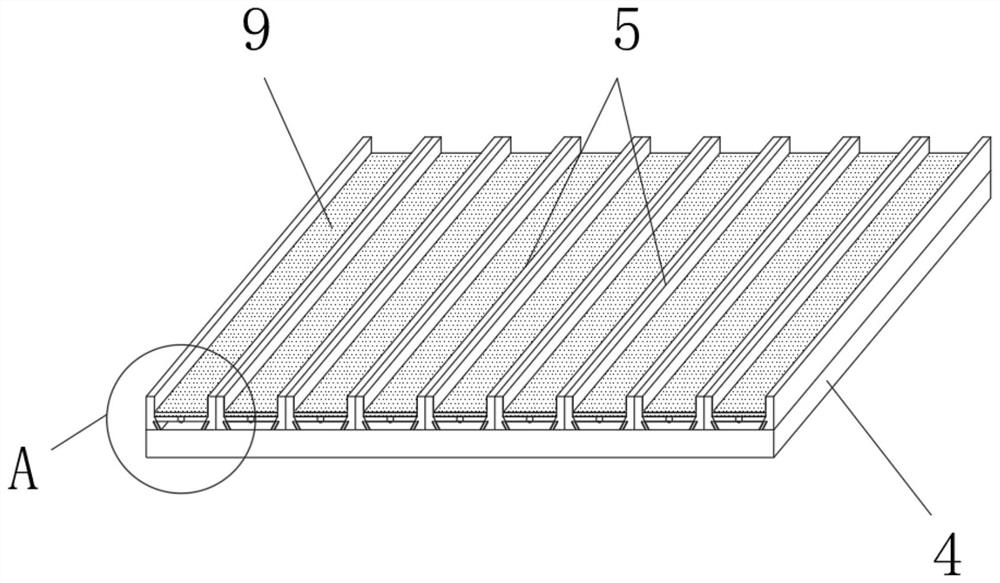

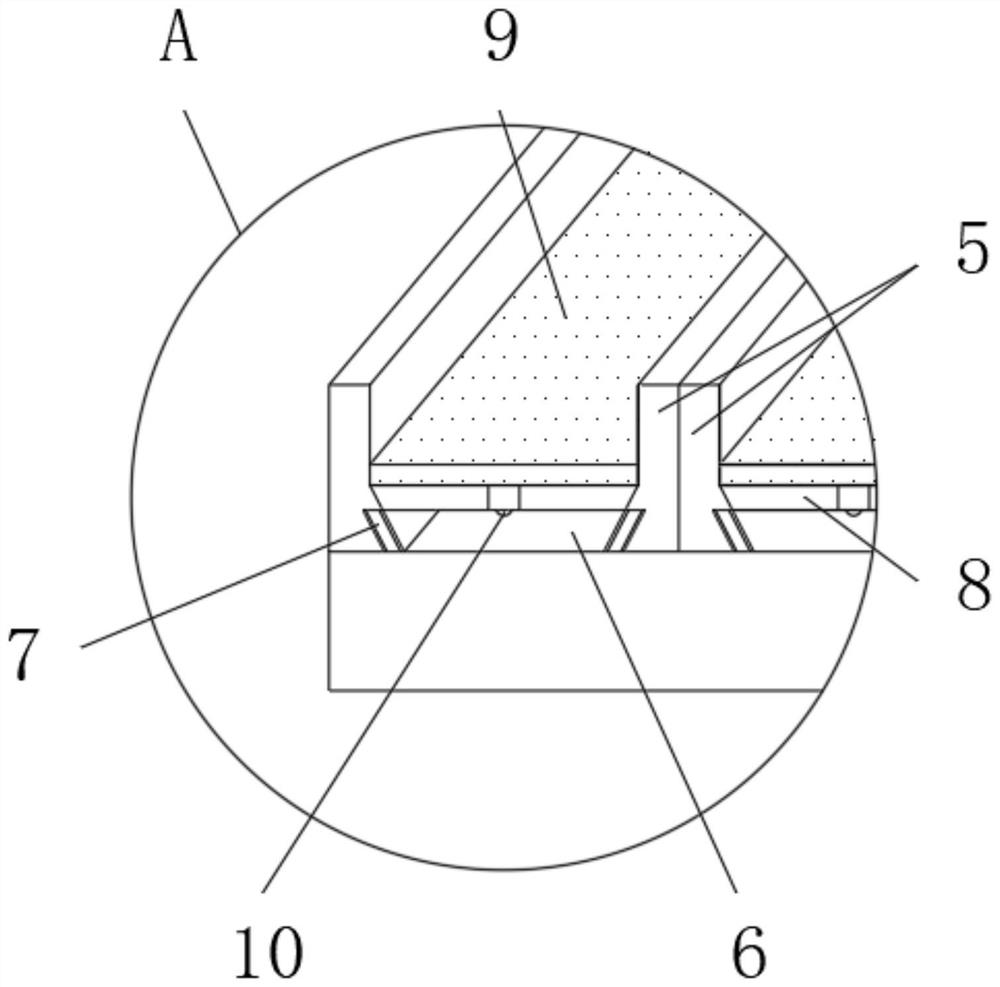

[0042] like figure 1 As shown, a kind of anti-seepage drainage structure includes a building base plate 4, the upper end surface of the building base plate 4 is fixedly connected with an anti-seepage frame 5, and the middle part of the anti-seepage frame 5 is embedded with a water-collecting groove 6, and the water-collecting groove 6 The upper end surface is fixedly connected with a support frame 8, and the upper end surface cover of the support frame 8 is provided with a partition plate 9, and the support frame 8 and the partition plate 9 are located inside the anti-seepage frame 5, between the partition plate 9 and the anti-seepage frame 5 The upper part of the gap between them is filled with a structural layer 3, the upper end surface of the structural layer 3 is level with the upper end surface of the anti-seepage frame 5, the upper end surface of the structural layer 3 is coated with a waterproof layer 2, and the upper end surface of the waterproof layer 2 is installed wi...

Embodiment 2

[0045] like Figure 1-3 As shown, the inner wall of the water-collecting embedding groove 6 is inclined, and the water-collecting embedding groove 6 is funnel-shaped.

[0046] During use, by setting the inner wall of the water-collecting groove 6 into an inclined state, it is convenient to infiltrate moisture in the waterproof layer 2 along the anti-seepage frame 5 and

[0047] The inner wall of the water collection embedding groove 6 stays and gradually gathers.

[0048] like Figure 1-6 As shown, the bottom of the water-collecting groove 6 is fixedly connected with a drain pipe 11, and the end surface of the drain pipe 11 and the water-collecting groove 6 is fixedly connected with an extension rod 12, and the middle part of the lower end surface of the extension rod 12 is fixedly connected with a second collecting protrusion. 13, and the lower end surface of the support frame 8 is fixedly connected with the first collector protrusion 10, the first collector protrusion 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com