Slotted nut structure and nut locking method adopting screw for jacking

A technology of slotted nuts and nut bodies, which is applied in the direction of screws, nuts, bolts, etc., which can solve the problems such as the difficulty of loosening the bearing gap adjustment nut, and achieve the effects of simple structure, dynamic balance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in connection with the examples below:

[0029] In order to make the technical solutions and advantages of the present invention more clearly, exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Obviously, the described embodiments are merely the embodiment of the invention, not the exhaustion of all embodiments. And in the case of an unable conflict, the features of the present invention and the features in the embodiments in the present invention can be combined with each other.

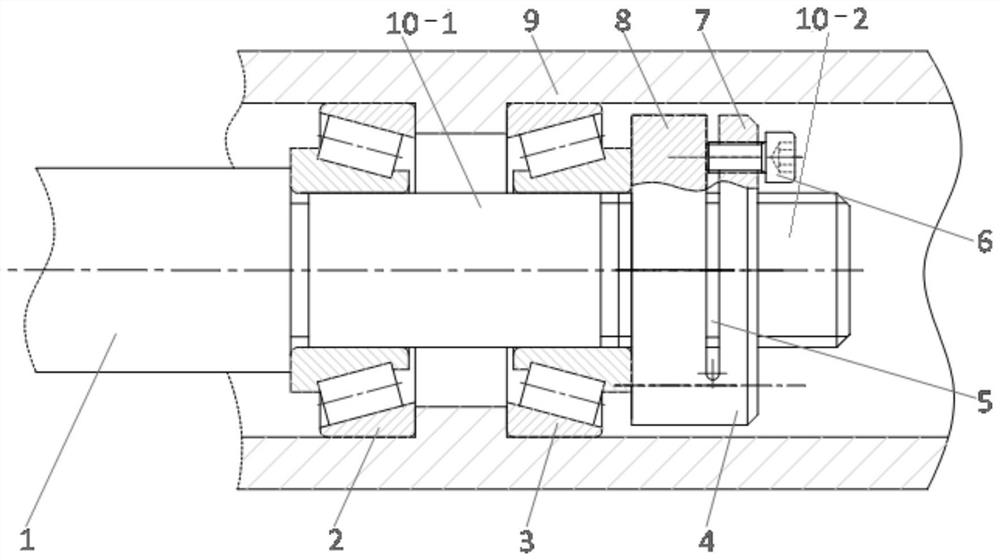

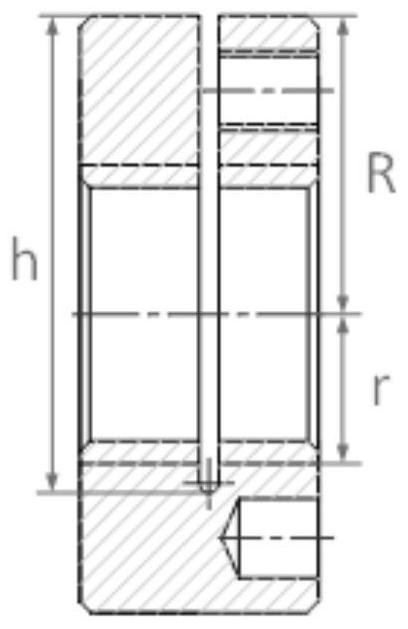

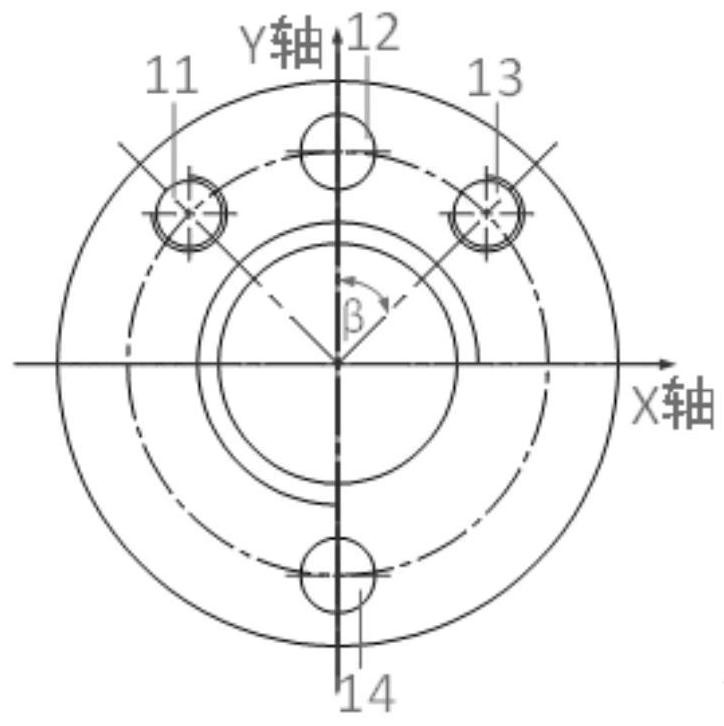

[0030] like Figure 1 to 6As shown, a slotted nut structure includes a slotting nut 4 and a top pressure screw 6 having a material having good elastic material after heat treatment, and the groove nut 4 is shown after processing. Circular, the slotted nut 4 column is dialed radially in radially, the locking groove 5 divides the slotting nut 4 into a nut body A7 and a nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com