Method for predicting cycle life and residual life of lithium ion battery

A lithium-ion battery and cycle life technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of lengthening the evaluation test cycle and affecting the development progress, etc., and achieve the effect of shortening the test cycle and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Establishment of electrolyte content detection method:

[0031] Step 1: Make a reference battery Ref Cell according to the battery model to be tested. The difference between the reference battery and the normal battery is that the reference battery is injected with absolute ethanol or other organic solvents whose solidification temperature is lower than the solidification temperature range of the electrolyte, while the normal battery is injected with the electrolyte, and then press Normal process package.

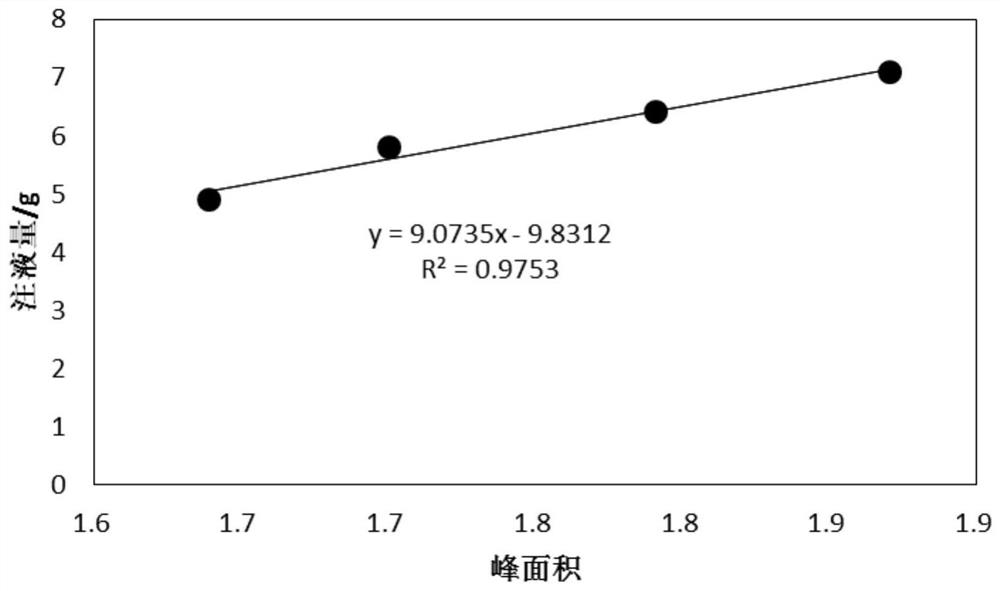

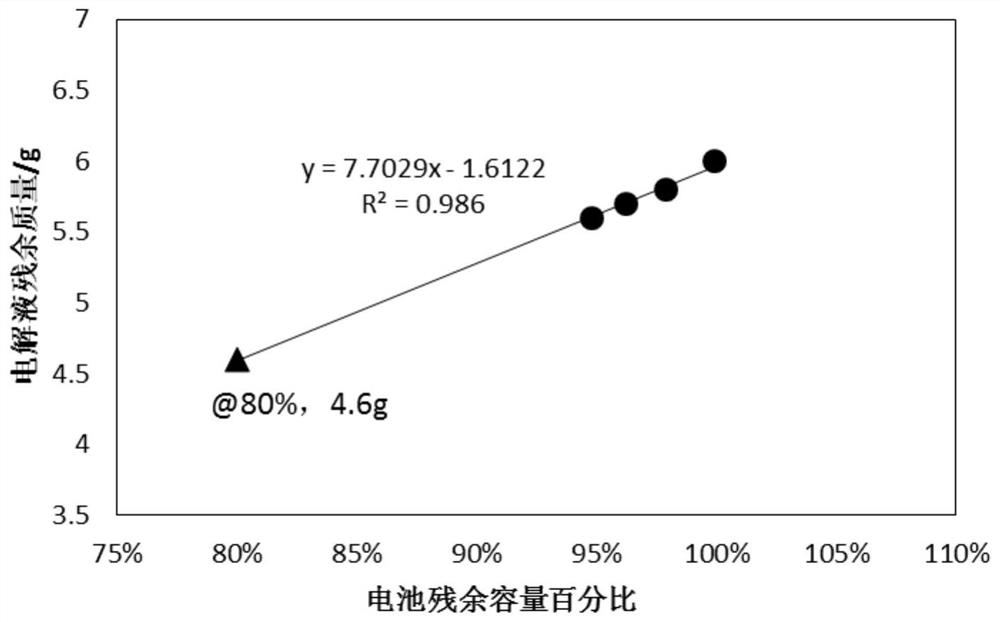

[0032] Step 2: Fabrication of series batteries with different electrolyte contents. In order to carry out the quantitative calculation of the electrolyte content in the battery, referring to the test principle of the external standard method, a series of batteries with different electrolyte content were produced. 4.9g.

[0033] Step 3: The reference battery and the battery with different electrolyte content are tested and analyzed with the established in-situ d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com