Ferritic stainless steel sheet and method for producing same

A technology of stainless steel plate and manufacturing method, which is applied to manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as cracks and cracks in steel plates, and achieve the effect of excellent hydrogen embrittlement resistance and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

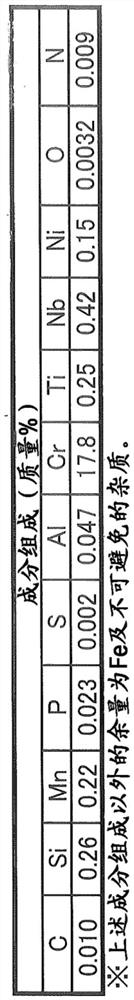

[0167] Ferritic stainless steel having the composition shown in Table 1-1 was melted into a 100 kg steel ingot, heated at a temperature of 1150° C. for 1 hour, and hot rolled so that the plate thickness became 3.0 mm. The hot-rolled sheet is air-cooled immediately after the final pass of hot-rolling.

[0168] [Table 1-1]

[0169]

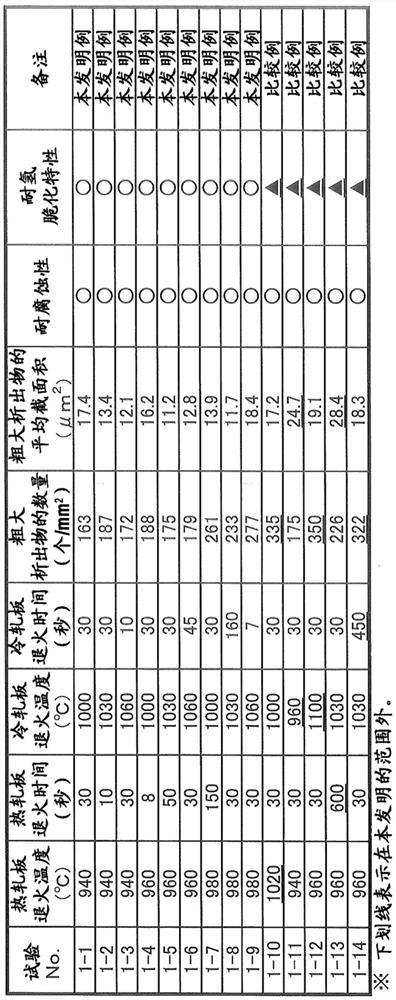

[0170] The obtained hot-rolled sheet was kept at the annealing temperature of each hot-rolled sheet recorded in Table 1-2 for the annealing time of each hot-rolled sheet described in Table 1-2, and then air-cooled to produce a hot-rolled annealed sheet.

[0171] The hot-rolled annealed sheet is first pickled in a sulfuric acid solution and then in a mixed solution of hydrofluoric acid and nitric acid to produce a raw material for cold rolling, and then cold-rolled to a thickness of 1.0 mm to obtain a cold-rolled sheet. plate.

[0172] After keeping the cold-rolled sheet annealing temperature recorded in Table 1-2 for the annealing time of each co...

Embodiment 2

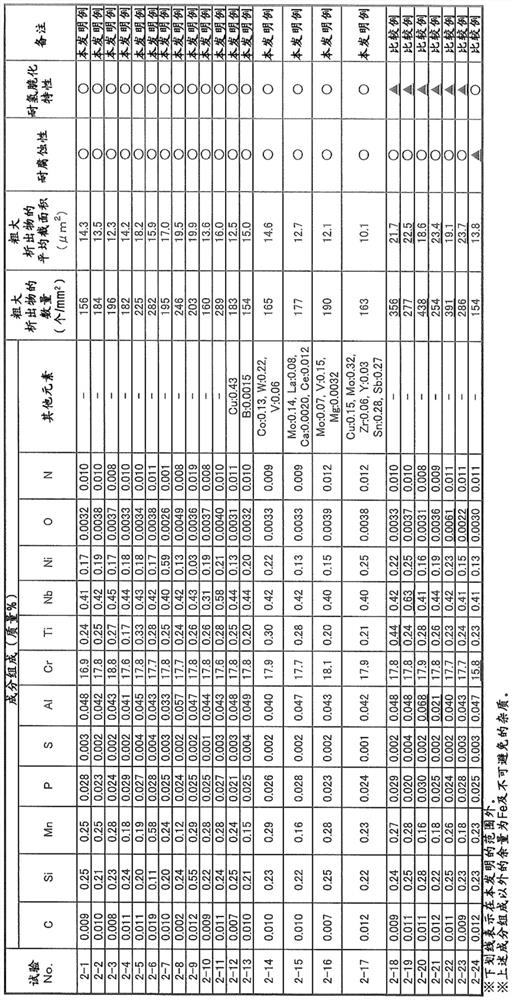

[0205] After melting the ferritic stainless steel having the composition shown in Table 2 into a 100 kg ingot, it was heated at a temperature of 1150° C. for 1 hour, and hot rolled so that the sheet thickness would be 3.0 mm. The hot-rolled sheet is air-cooled immediately after the final pass of hot-rolling.

[0206] The obtained hot-rolled sheet was held at 940° C. for 10 seconds, and then air-cooled to obtain a hot-rolled annealed sheet.

[0207] The hot-rolled annealed sheet was pickled first in a sulfuric acid solution and then in a mixed solution of hydrofluoric acid and nitric acid to prepare a raw material for cold rolling, and then cold-rolled to a thickness of 1.0 mm to obtain a cold-rolled sheet.

[0208] After holding the obtained cold-rolled sheet at 1040° C. for 45 seconds, it was air-cooled, and then the surface was ground to remove the surface scale layer to obtain a cold-rolled annealed sheet.

[0209] The above-mentioned evaluations were performed on the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com