Printed lithium foil and film

A technology of lithium metal powder and substrate, applied in the field of substrates coated with a printable lithium composition, can solve problems such as loss of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

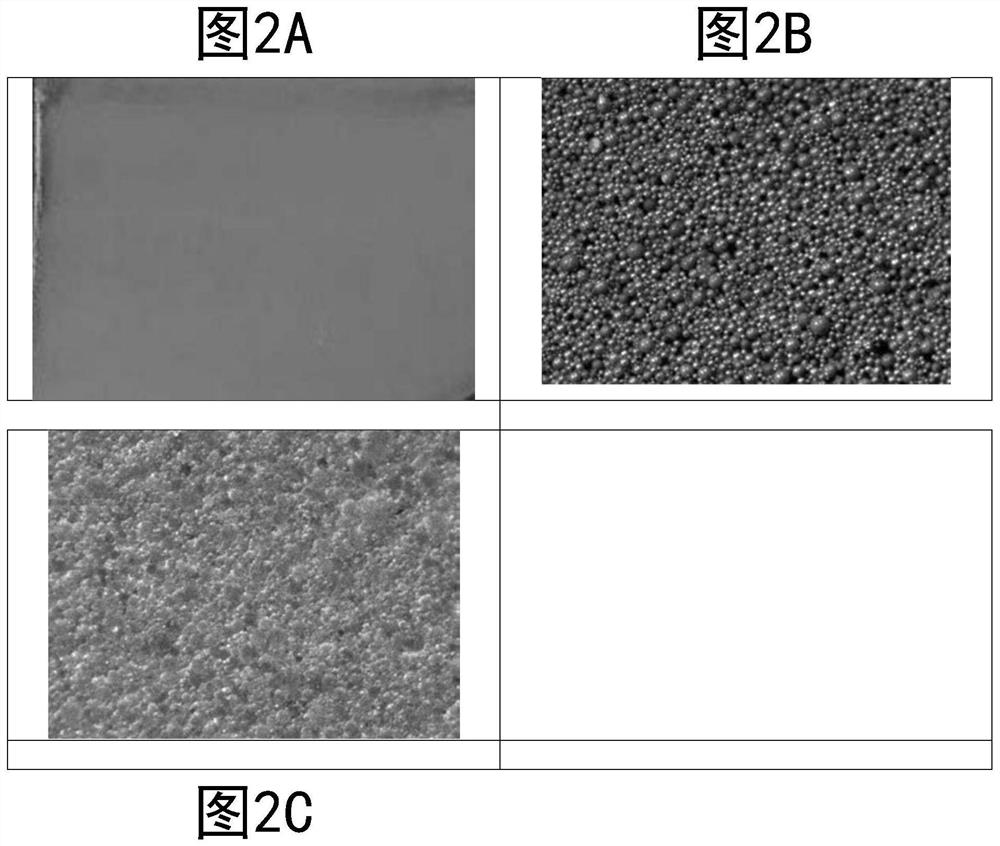

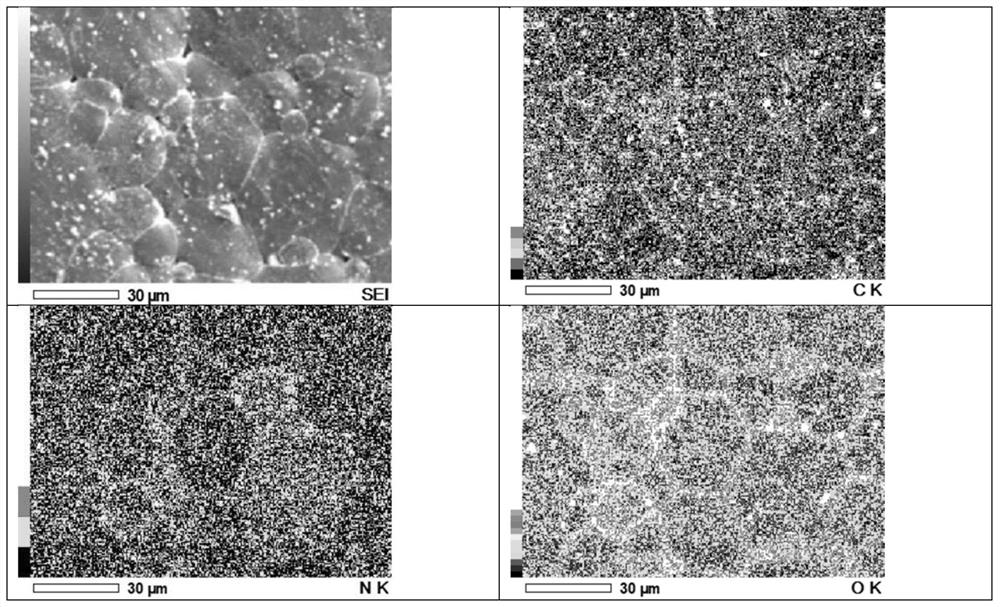

[0082] 10 g of styrene-butadiene rubber solution (S-SBR Europrene Sol R 72613) was dissolved in 90 g of toluene (99% anhydrous, Sigma Aldrich) by stirring at 21° C. for 12 hours. 6 g of 10 wt% styrene-butadiene rubber (polymer binder) in toluene (solvent) was mixed with 0.1 g of carbon black (Timcal Super P) (rheology modifier) and 16 g of toluene, and mixed in a Thinky ARE 250 Disperse in a planetary mixer at 2000 rpm for 6 minutes. 9.3 g of stabilized lithium metal powder ( FMC Lithium Corp.) was added to the suspension and dispersed in a Thinky mixer at 1000 rpm for 3 minutes. The printable lithium suspension was then filtered through a stainless steel mesh with 180 μm openings. The printable lithium suspension was then blade coated onto the copper current collector at a wet thickness of 2 mils (-50 μm) and a dry thickness of approximately 25 μm before lamination. Figure 4 is a graph showing the cycle performance of a pouch cell with a printable lithium-derived thin ...

Embodiment 2

[0084] 10 g of ethylene propylene diene terpolymer (EPDM) with a molecular weight of 135,000 (Dow Nordel IP 4725P) were dissolved in 90 g of p-xylene (99% anhydrous, Sigma Aldrich) by stirring at 21° C. for 12 hours. 6 g of 10 wt % EPDM (polymer binder) in p-xylene (solvent) was mixed with 0.1 g TiO 2(Evonik Industries) (rheology modifier) and 16 g of toluene were combined and dispersed in a Thinky ARE 250 planetary mixer at 2000 rpm for 6 minutes. 9.3 g of stabilized lithium metal powder ( FMCLithium Corp.) was added to the suspension and dispersed in a Thinky mixer at 1000 rpm for 3 minutes. The printable lithium was then filtered through a stainless steel mesh with 180 μm openings. The printable lithium composition was then blade coated onto the copper current collector at a wet thickness of 2 mils (~50 μm) and a dry thickness of approximately 25 μm prior to lamination.

Embodiment 3

[0085] Example 3 - Printed foil with carbon nanotubes

[0086] 1.5 g of 1.27M molecular weight polyisobutylene (PIB) was dissolved in toluene by stirring at 21°C for 12 hours. 30 g of stabilized lithium metal powder ( FMCLithium Corp.) was added to the suspension and dispersed in a Thinky mixer at 1000 rpm for 3 minutes. The printable lithium suspension was then filtered through a stainless steel mesh with 180 μm openings. The printable lithium composition was then blade coated onto the copper current collector at a wet thickness of 2 mils (~50 μm) and a dry thickness of approximately 25 μm prior to lamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com