Peeling and milling processing device

A kind of processing equipment and grinding technology, which is applied in the field of peeling and grinding processing equipment, can solve the problems of uneven peeling and grinding, complex equipment structure, and low processing precision, and achieve uniform peeling and grinding, simple processing steps, and high processing accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

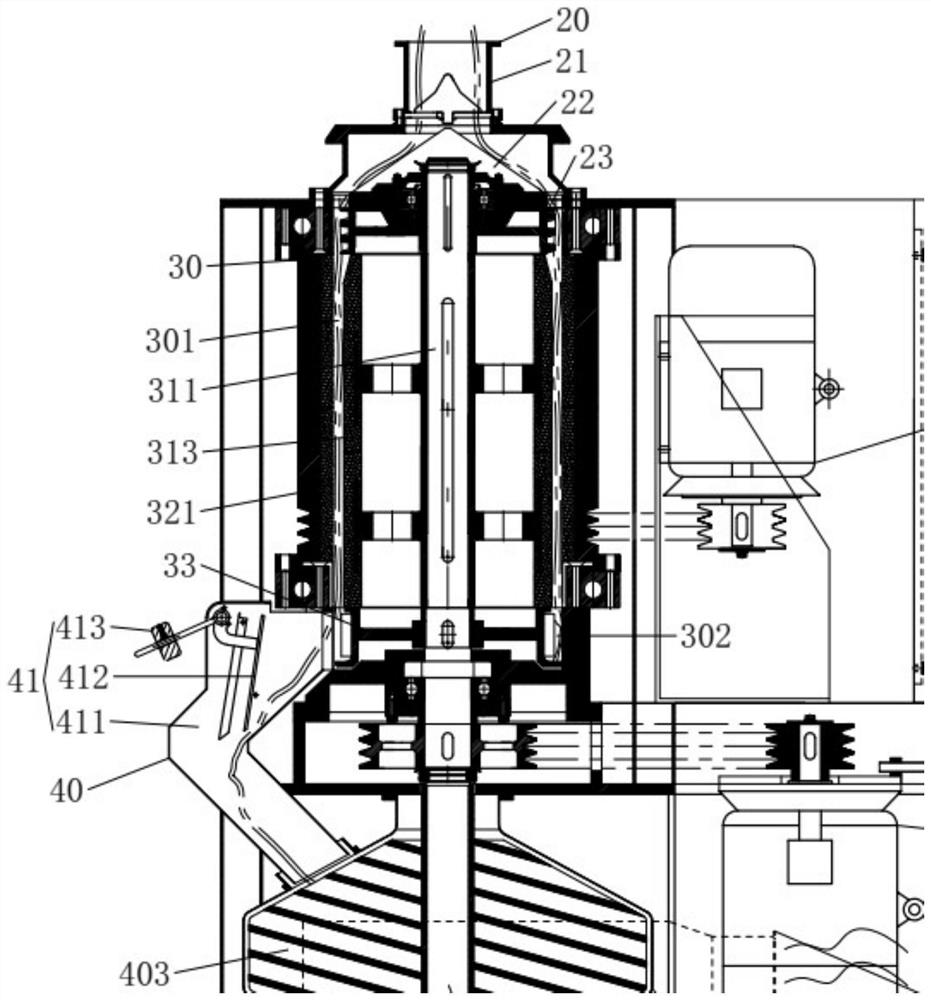

[0026] refer to figure 1 , the preferred embodiment of the present invention provides a peeling and grinding processing equipment, including: an installation frame 10, and a feeding and homogeneous material device 20, a grinding and peeling device 30, and a discharge separation device arranged on the installation frame 10. 40, and the electrical control device 50, and the feeding and screeding device 20, the grinding and peeling device 30, and the discharging separation device 40 are sequentially arranged and communicated along the processing direction of the raw grain material, and the grinding and peeling device 30 and the discharging separation device 40 are also in communication with electrical control devices 50, respectively. The feeding and leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com