Drying frame bent pipe lap joint chambering forming machine

A technology for drying racks and forming machines, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of high cost, unstable product quality, and heavy repair workload, so as to improve quality and production efficiency, reduce Defect rate and rework workload, the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

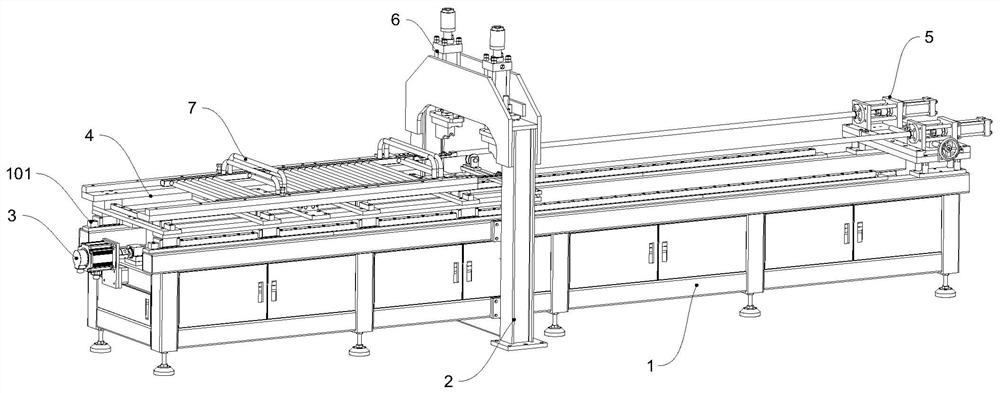

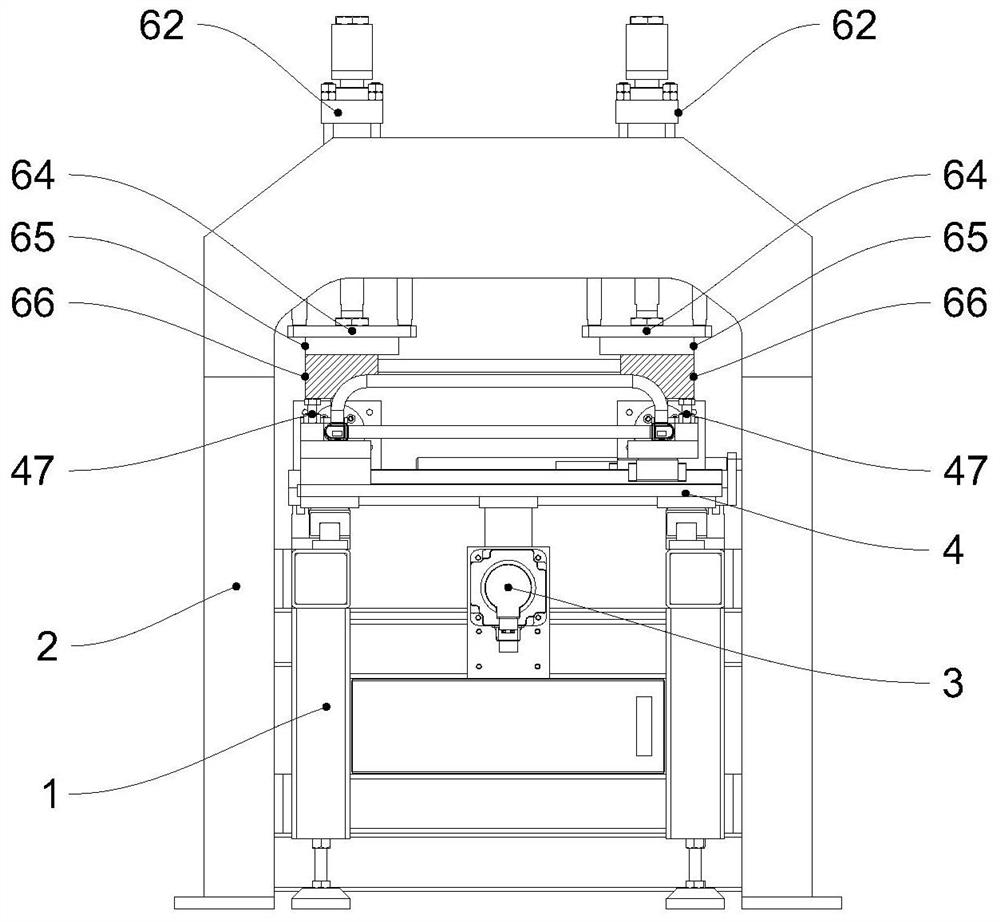

[0024] next combined with Figure 1-7 A specific embodiment of the present invention is described in detail.

[0025] In this embodiment, the direction of the X-axis is taken as the longitudinal direction of the fuselage 1 , that is, the traveling direction of the drying rack 7 to be expanded.

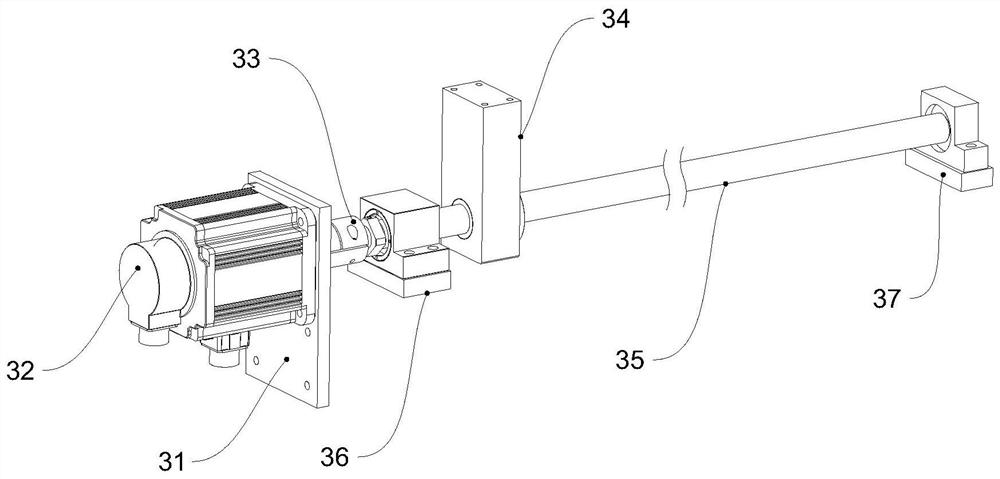

[0026] A drying rack elbow lap expansion forming machine, including a fuselage 1 as a main load-bearing structure, a door frame 2, a feed drive assembly 3, a movable workbench 4, a pipe expansion assembly 5, and a pressure pipe assembly 6, The fuselage 1 is provided with two linear slide rails 101 arranged along the X-axis, the movable table 4 is movably arranged on the slide rails 101, the feed drive assembly 3 is fixed at one end of the fuselage 1, and the output of the feed drive assembly 3 The movable workbench 4 is connected to drive the movable workbench 4 to perform feed movement along the X axis, the drying rack 7 is placed on the movable workbench 4, and the movable workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com