Accompanying clamping device of electromechanical actuator shell

A technology of electromechanical actuators and clamping devices, which is applied in the direction of clamping devices, positioning devices, clamping, etc., can solve the problems of not meeting the needs of automatic production lines, reducing tooling matching and management costs, and high tooling matching and management costs , to achieve the effect of reducing the demand for tooling, saving tooling costs, and improving processing quality and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with embodiment.

[0035] The invention provides an accompanying clamping device for electromechanical actuator housings. By adding a process clamp, the structural differences of the product itself are avoided. In addition to the product's own structure, a unified process clamp is added as a positioning and clamping reference. Change the positioning and clamping mode of the parts, unify the positioning references of the shells of various types of electromechanical actuators, simplify the types and quantities of tooling, and provide the necessary conditions for the subsequent application of universal accompanying tooling.

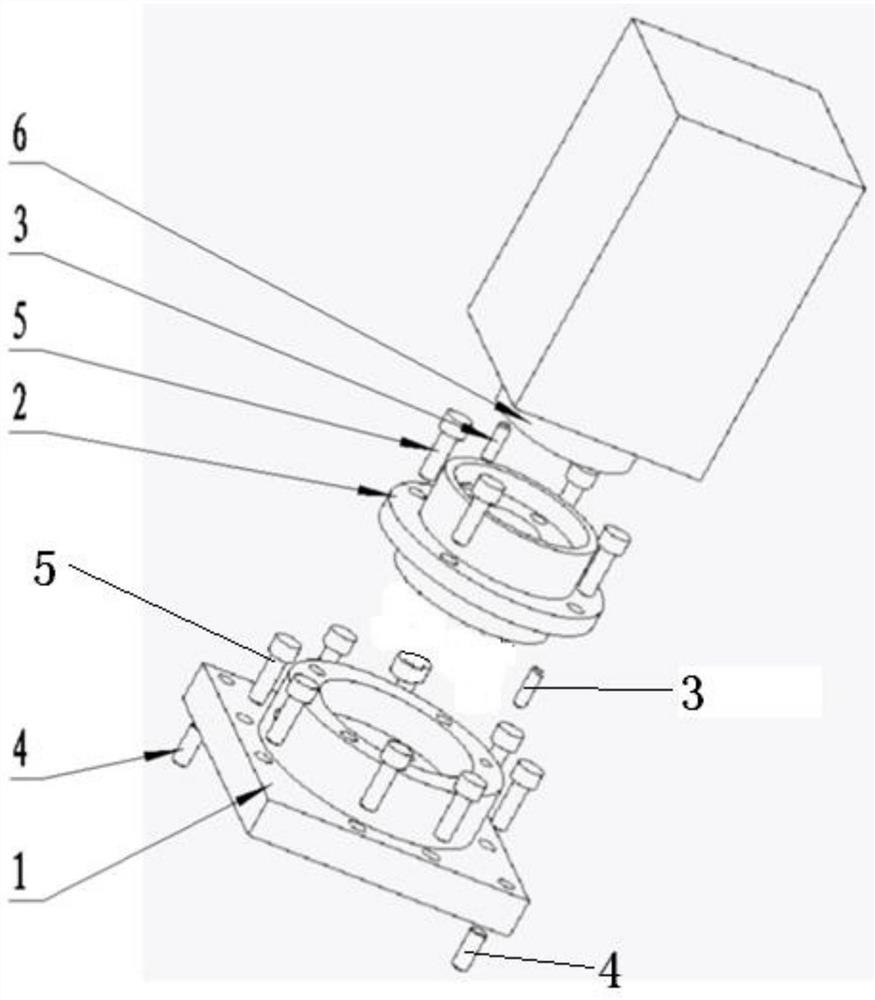

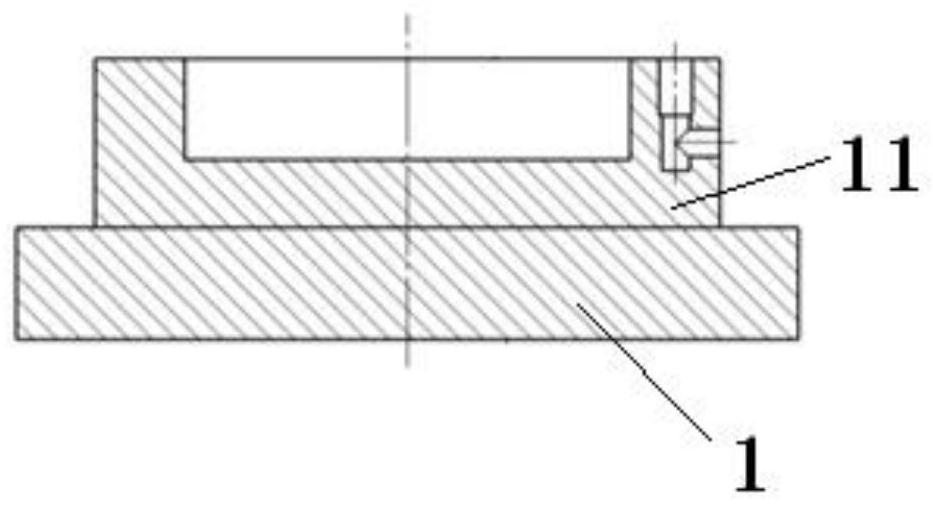

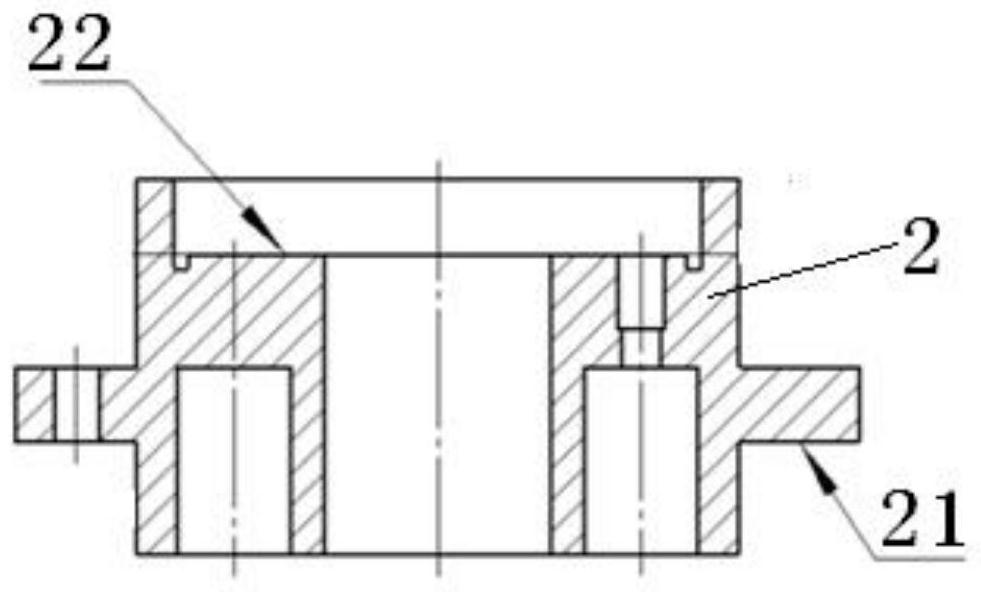

[0036] Pallet clamping devices such as figure 1 As shown, it specifically includes a base 1, an accompanying module 2, 2 positioning pins 3, 2 cylindrical pins 4, 12 bolts 5 and a process chuck 6; wherein, the base 1 is a square plate-shaped structure; the base 1 is placed horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com