Rapid repairing device and method

A fast and component-based technology, applied in the direction of spraying devices, grinders, spray booths, etc., can solve problems such as tight maintenance cycle, inability to quickly repair the surface corrosion of aluminum valve blocks, and affect product use, so as to reduce maintenance time and achieve significant effects. The effect of reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

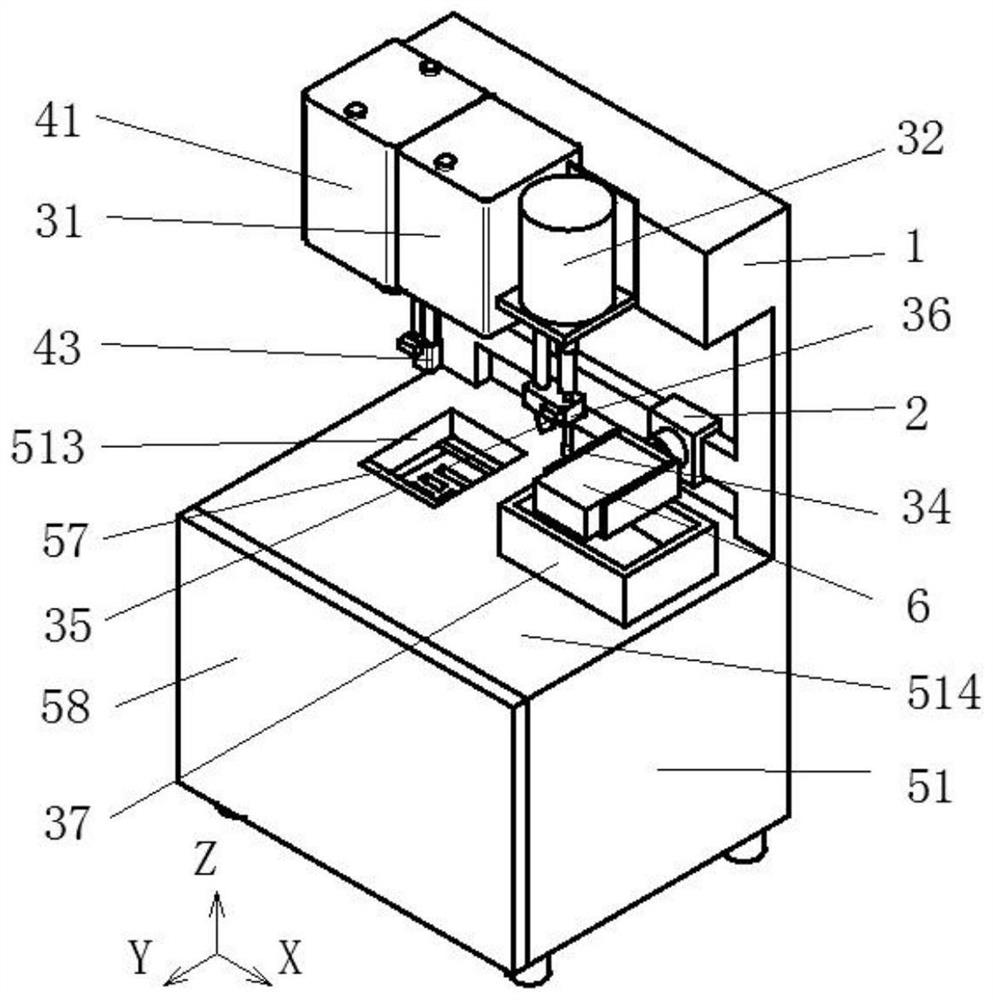

[0066] Please also refer to Figure 1 to Figure 13 Now, a specific implementation of a quick repair device provided by the present invention will be described. This kind of quick repair device includes a frame body 1, a gripper 2, a grinding and washing assembly 3, a repair assembly 4 and a reinforcement assembly 5, wherein the frame body 1 is provided with a slide rail 11; the gripper 2 is slidably connected with the slide rail 11, and the gripper 2 is used to clamp and move the workpiece 6; the grinding and washing assembly 3 is connected to the frame body 1; the repairing assembly 4 is connected to the frame body 1 and is arranged on one side of the grinding and washing assembly 3; The installation direction is parallel to the installation direction of the slide rail 11 ; the reinforcement assembly 5 is connected to the frame body 1 , and the slide rail 11 is arranged between the reinforcement assembly 5 and the grinding assembly 3 .

[0067] For clarification, see image...

Embodiment 2

[0071] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 13 , the structure of a quick repair device provided by this embodiment is basically the same as that of Embodiment 1, the difference is that the grinding and washing assembly 3 includes a liquid storage part 31, a rotator 32, a first pusher 33, a grinding head 34, a water outlet The head 35 and the fixed block 36, wherein the liquid storage part 31 is arranged on the frame body 1, which can be a tank for storing cleaning agent; the rotator 32 is arranged on one side of the liquid storage part 31, which can be a motor; the first pusher 33 Connected with the rotator 32, it can be a cylinder; the grinding head 34 is detachably connected with the first pusher 33, the grinding head 34 can be replaced according to the accuracy requirements, and at the same time it is convenient for the maintenance of the grinding head 34; the water outlet 35 and the liquid storage par...

Embodiment 3

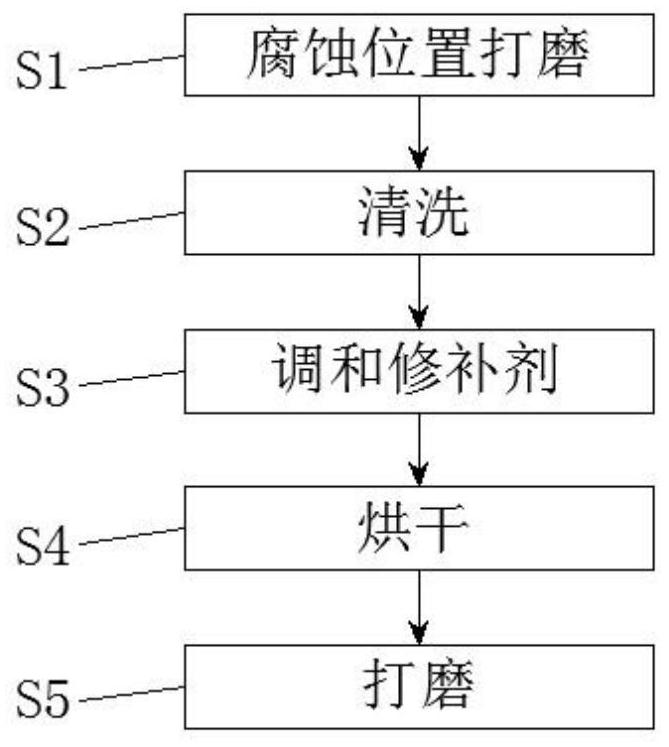

[0080] Please also refer to Figure 1 to Figure 13 Now, a specific implementation of a quick repair method provided by the present invention will be described. The specific steps of this quick repair method include:

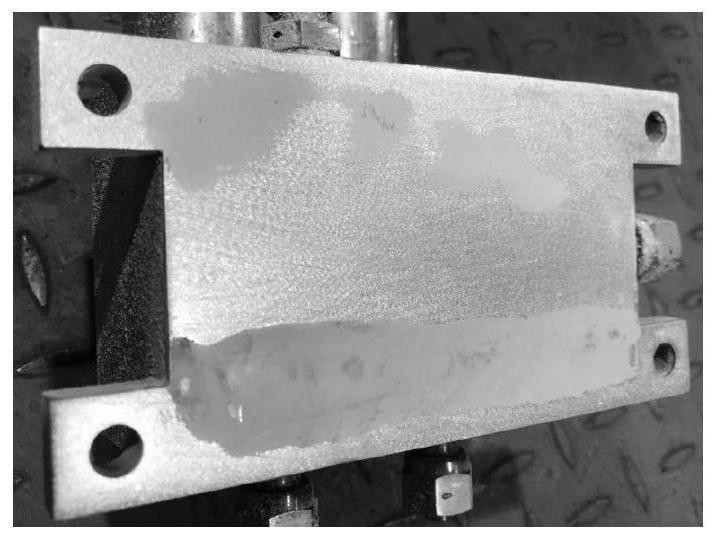

[0081] S1. Use a grinder to roughly grind the corroded position of the surface of the workpiece 6 until the substrate of the workpiece 6 is exposed, and then perform fine grinding with sandpaper after the substrate is exposed. Exemplarily, the workpiece 6 is an aluminum valve block with corrosion;

[0082] S2, using a cleaning agent to clean the surface of the polished workpiece 6;

[0083] S3, fully stir the repairing agent evenly, and quickly apply it to the position of the workpiece 6 to be repaired, wherein the repairing agent is a mixture of silicon dioxide and epoxy resin glue;

[0084] In S3, the volume fraction ratio of silicon dioxide and epoxy resin glue is 1:4-6, for example, the volume fraction ratio may be 1:5.

[0085] S4. Place the repaired work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com