Plastic regeneration particle treatment process

A treatment process and plastic granule technology, which is applied in the field of plastic recycled granule treatment process, can solve the problems of plastic damp, reduce the quality of plastic finished products, affect the quality of plastic granules, etc., and achieve the effect of preventing moisture and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

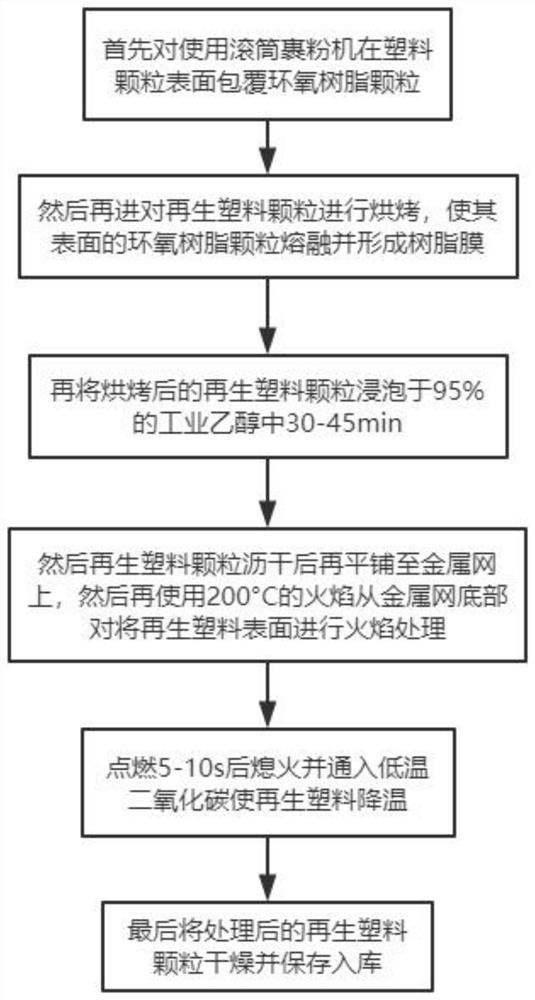

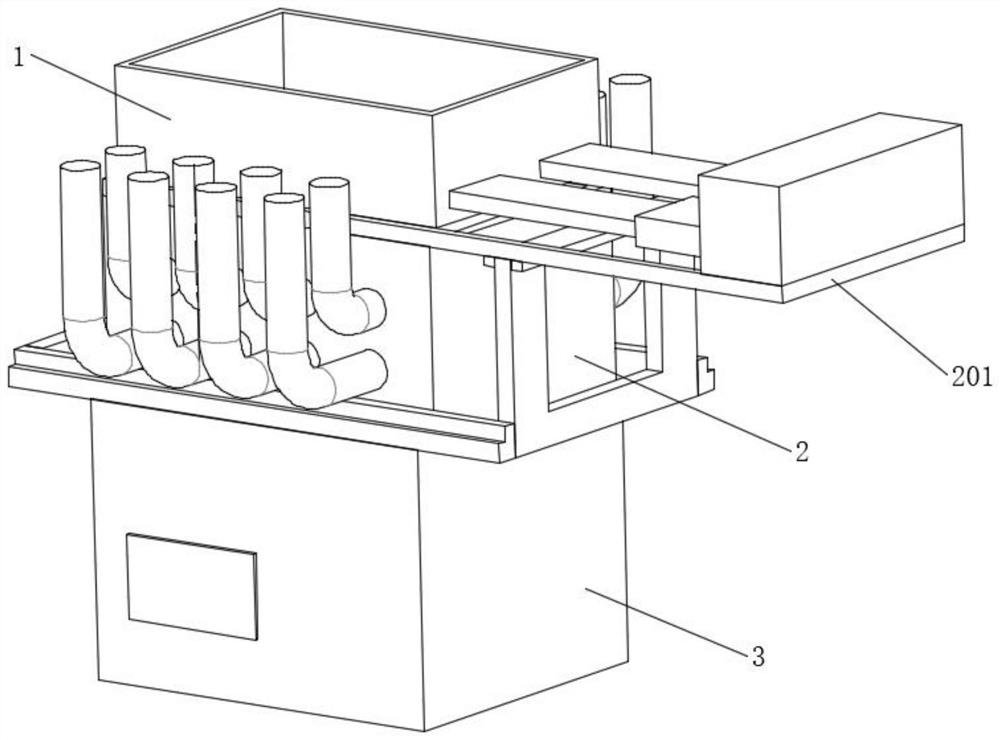

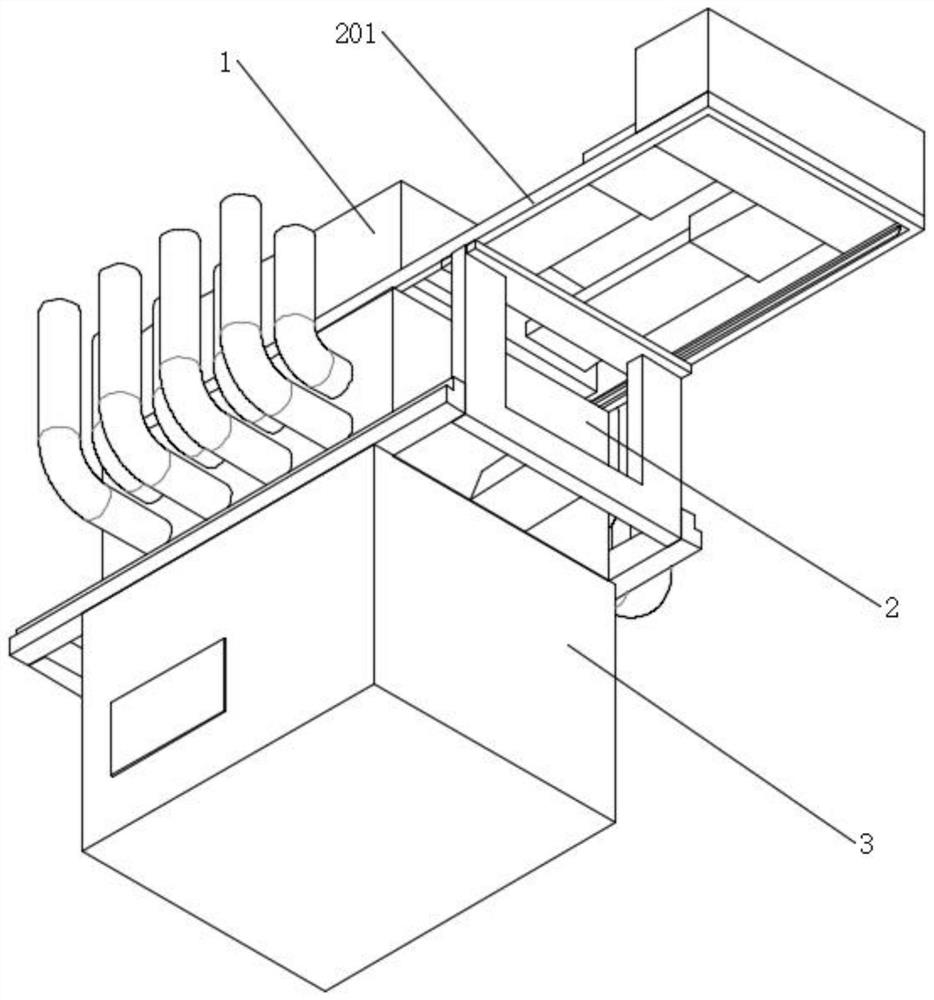

[0048] see Figure 1-8 , a process for treating recycled plastic particles, comprising the following steps:

[0049] S1, first, use a roller powder coating machine to coat epoxy resin particles on the surface of plastic particles, and the epoxy resin particles are pretreated. The pretreatment method is: use alkaline solution to soak the epoxy resin raw material to reduce the water absorption of the epoxy resin To prevent the epoxy resin from absorbing a large amount of water by reducing the adsorption of the epoxy resin, to prevent the generation of air bubbles on the recycled plastic particles after treatment, and to use the pretreated epoxy resin particles after drying. Epoxy resin particles at 400°C, recycled plastic particles with a ignition point higher than 500°C, and the melting points of both epoxy resin particles and recycled plastic particles are lower than 300°C;

[0050] S2, and then proceed to bake the recycled plastic particles to melt the epoxy resin particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com