Air rail transportation device for bulk materials

A transportation device and air rail technology, which is applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of difficult equipment installation and maintenance, high investment costs, and low transportation energy consumption. The effect of popular application, low operating energy consumption, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

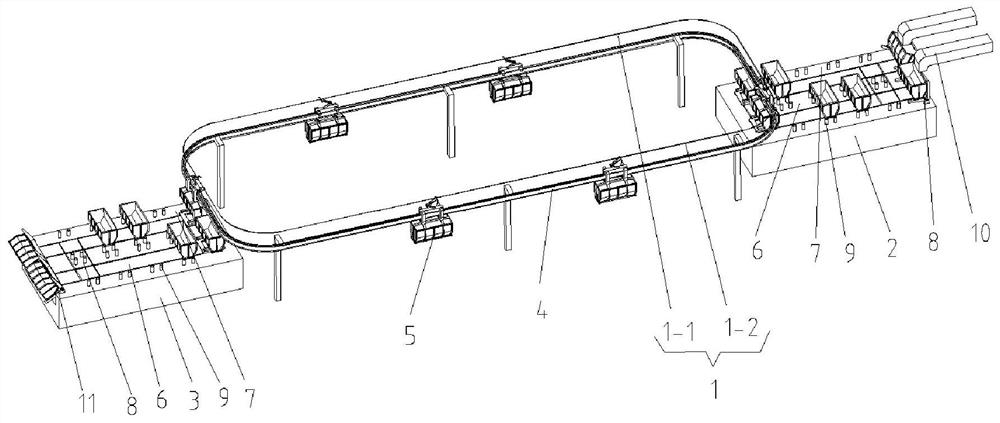

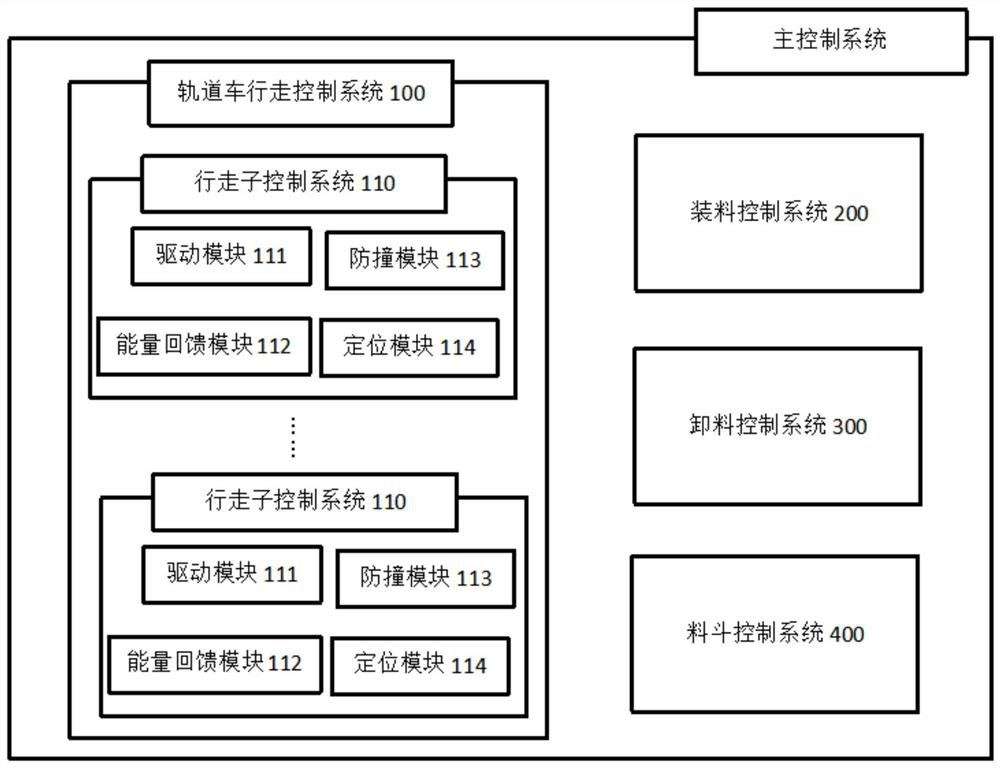

[0045] The empty rail transportation device of the bulk material that present embodiment provides, as figure 1 As shown, it includes a closed-loop empty rail 1, a loading platform 2, and an unloading platform 3. The loading platform 2 and the unloading platform 3 are respectively located outside the closed-loop empty rail 1.

[0046] Among them, such as figure 1 As shown, the closed-loop empty rail 1 includes an upward empty rail 1-1 along the direction from the loading platform 2 to the unloading platform 3, a downward empty rail 1-2 along the direction from the unloading platform 3 to the loading platform 1, and the upward empty rail The rail 1-1 and the descending empty rail 1-2 are all inclined orbits, the inclination angle of the ascending empty rail 1-1 is -a, and the inclination angle of the descending empty rail 1-2 is a, wherein 0>a>5°. In this specific embodiment, a=1° is preferably selected, that is, the upward empty track 1-1 has a slope of -1°, and the downward e...

Embodiment 2

[0059] The structure of the empty rail transportation device for bulk materials in this embodiment is basically the same as that of the empty rail transportation device for bulk materials in Embodiment 1.

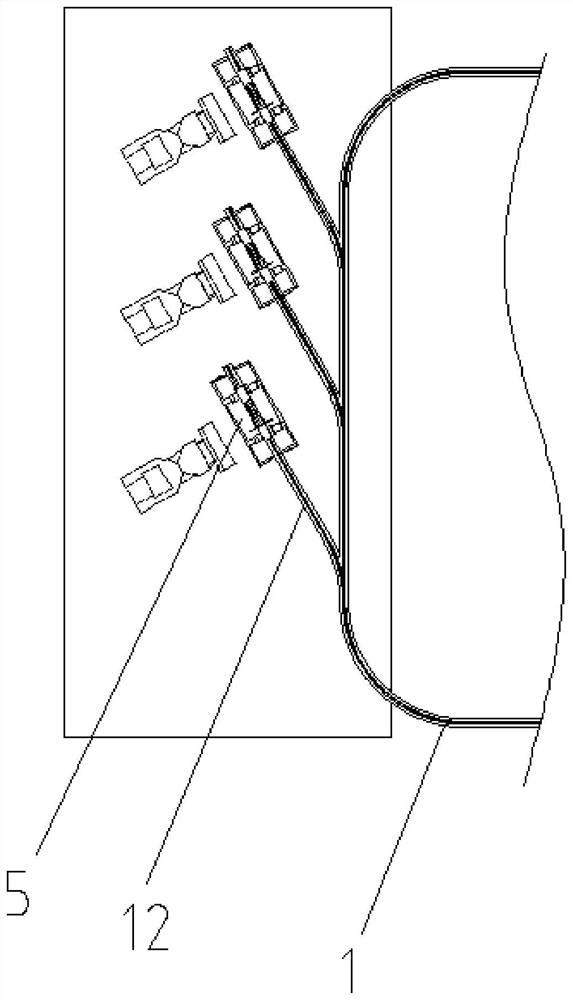

[0060] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that, in order to prevent the rail car 4 from staying on the closed-loop empty rail 1 for too long and affect the conveying efficiency of bulk materials, this embodiment is set on the closed-loop empty rail 1 and At least one extended empty rail 12 connected to the closed-loop empty rail 1, and the side of the extended empty rail 12 is provided with a loading platform 2 or an unloading platform 3 .

[0061] In this embodiment, in order to make the rail car 4 fully enter the extended empty rail 12 , the length of the extended empty rail 12 is greater than the length of the rail car 4 . When carrying out loading or unloading operation again, rail car 4 is entered in extension track 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com