Pellet flue gas denitrification method

A flue gas and pellet technology, applied in the field of flue gas denitration treatment, can solve the problems of large investment and increased pollutant discharge, and achieve the effects of less basic investment, saving treatment costs, and saving land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

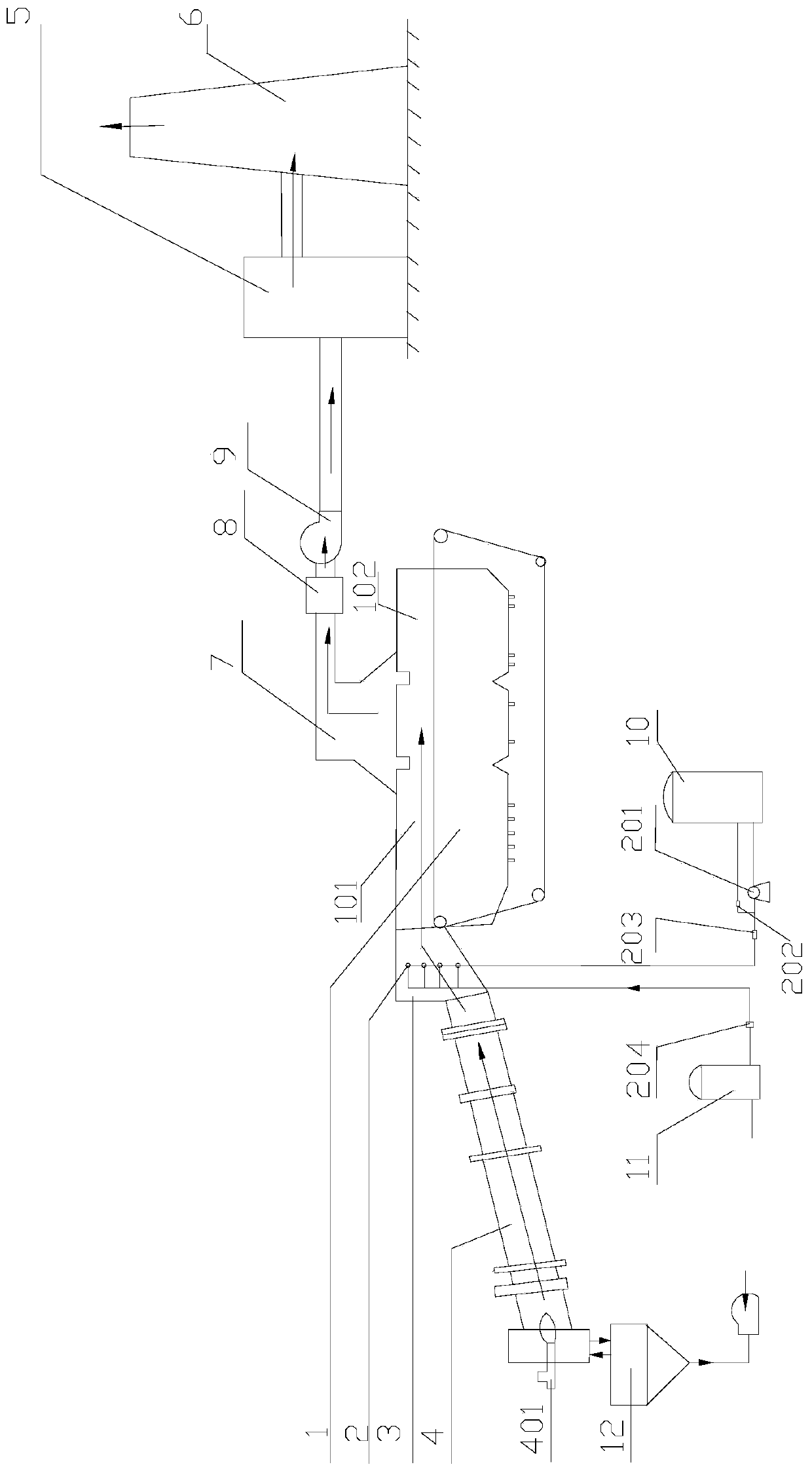

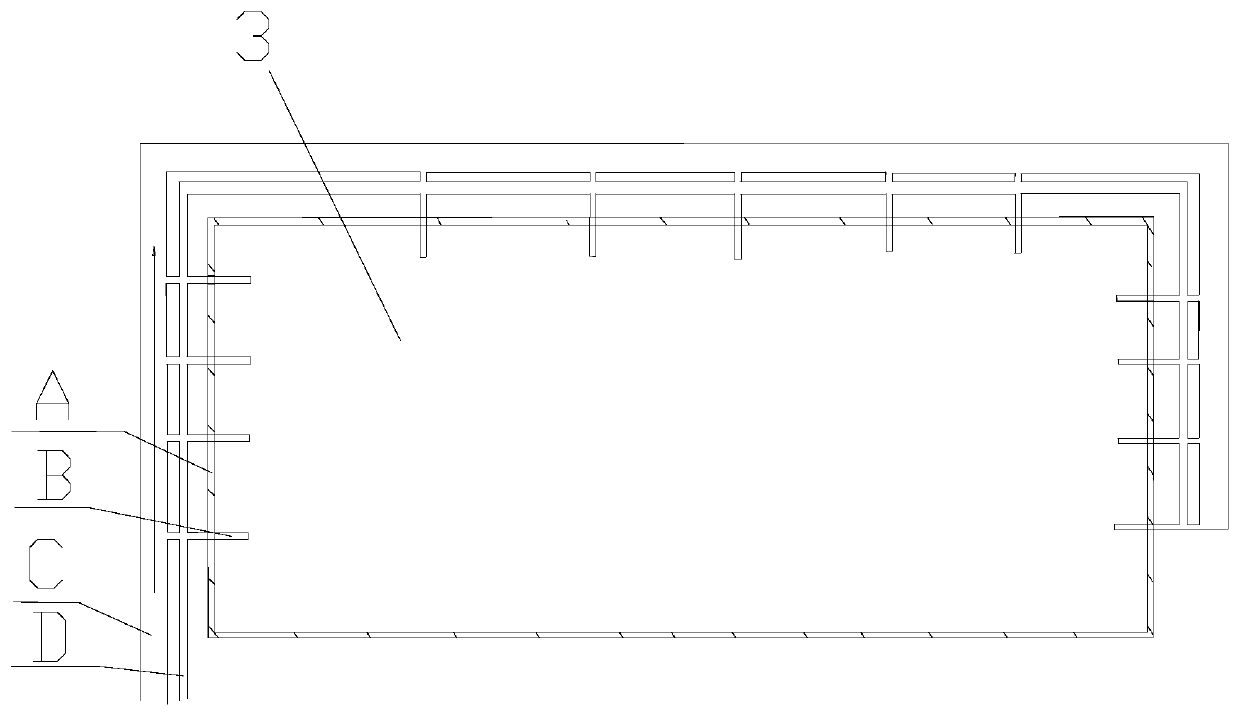

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0033] Such as figure 1 and figure 2 As shown, the present invention proposes a method for pelletizing flue gas denitrification, and the method for pelletizing flue gas denitrification includes:

[0034] Step A: Inject liquid reductant in the flue 3 between the pellet grate 1 and the pellet rotary kiln 4;

[0035] Step B: using the high temperature of the flue gas in the flue 3 to vaporize the droplets formed by the injected reducing agent into ammonia;

[0036] Step C: In the flue 3, the ammonia and the nitrogen oxides in the flue gas undergo a redox reaction, and the nitrogen oxides are reduced to nitrogen and water;

[0037] Step D: Make the remaining unreacted ammonia and flue gas enter the ammonia desulfurization tower 5 for recovery.

[0038] Further: Drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com