Refractory industrial wastewater treatment system and treatment method

A technology for industrial wastewater and treatment systems, applied in biological water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., to achieve the effect of good effect, less basic investment and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

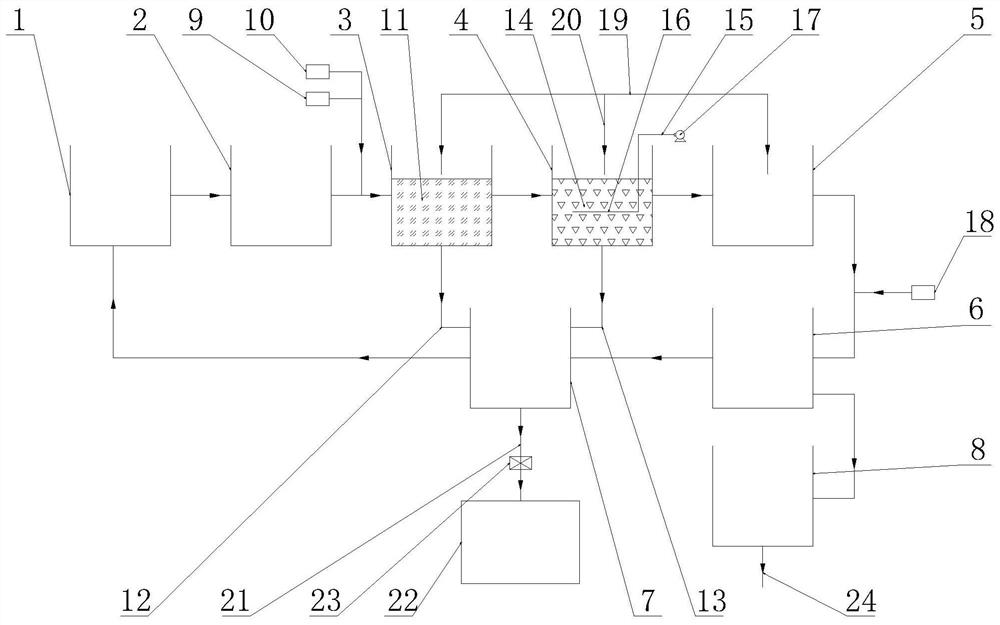

[0024] Embodiment 1 of the present invention: a refractory industrial wastewater treatment system, including a regulating tank 1, an ozone catalytic oxidation tank 2, a denitrification filter 3, a biological aerated filter 4, an intermediate pool 5, an active sand filter 6, The sludge thickening tank 7 and the ozone disinfection tank 8, the adjustment tank 1 is connected to the ozone catalytic oxidation tank 2 through pipelines, the ozone catalytic oxidation tank 2 is connected to the denitrification filter tank 3 through pipelines, the biological aerated filter tank 4 is connected to the intermediate pool 5 through pipelines, The intermediate pool 5 is connected to the pipeline of the active sand filter 6, the pipeline of the active sand filter 6 is connected to the sludge concentration tank 7, the pipeline of the sludge concentration tank 7 is connected to the regulation tank 1, and the pipeline of the ozone disinfection tank 8 is connected to the pipeline of the active sand f...

Embodiment 2

[0025] Embodiment 2 of the present invention: a refractory industrial wastewater treatment system, including a regulating tank 1, an ozone catalytic oxidation tank 2, a denitrification filter tank 3, a biological aerated filter tank 4, an intermediate pool 5, an active sand filter tank 6, The sludge thickening tank 7 and the ozone disinfection tank 8, the adjustment tank 1 is connected to the ozone catalytic oxidation tank 2 through pipelines, the ozone catalytic oxidation tank 2 is connected to the denitrification filter tank 3 through pipelines, the biological aerated filter tank 4 is connected to the intermediate pool 5 through pipelines, The intermediate pool 5 is connected to the pipeline of the active sand filter 6, the pipeline of the active sand filter 6 is connected to the sludge concentration tank 7, the pipeline of the sludge concentration tank 7 is connected to the regulation tank 1, and the pipeline of the ozone disinfection tank 8 is connected to the pipeline of th...

Embodiment 3

[0026] Embodiment 3 of the present invention: a refractory industrial wastewater treatment system, including a regulating tank 1, an ozone catalytic oxidation tank 2, a denitrification filter 3, a biological aerated filter 4, an intermediate pool 5, an active sand filter 6, The sludge thickening tank 7 and the ozone disinfection tank 8, the adjustment tank 1 is connected to the ozone catalytic oxidation tank 2 through pipelines, the ozone catalytic oxidation tank 2 is connected to the denitrification filter tank 3 through pipelines, the biological aerated filter tank 4 is connected to the intermediate pool 5 through pipelines, The intermediate pool 5 is connected to the pipeline of the active sand filter 6, the pipeline of the active sand filter 6 is connected to the sludge concentration tank 7, the pipeline of the sludge concentration tank 7 is connected to the regulation tank 1, and the pipeline of the ozone disinfection tank 8 is connected to the pipeline of the active sand f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com