Organic waste anaerobic digestion method

A technology for organic waste and anaerobic digestion, which is applied in chemical instruments and methods, waste fuel, biological sludge treatment, etc., and can solve problems such as poor mass transfer effect, low methane production efficiency, and long reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

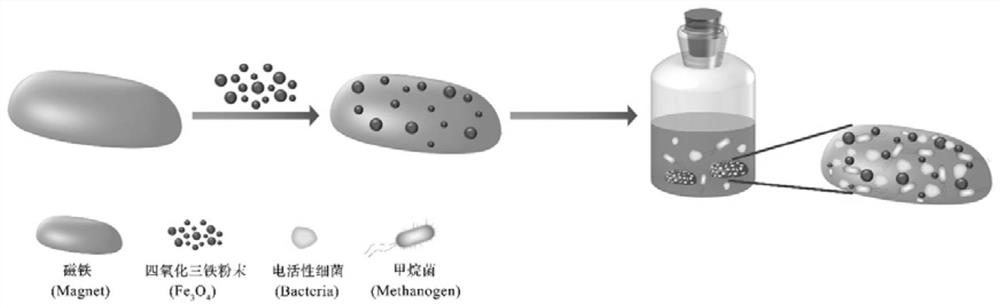

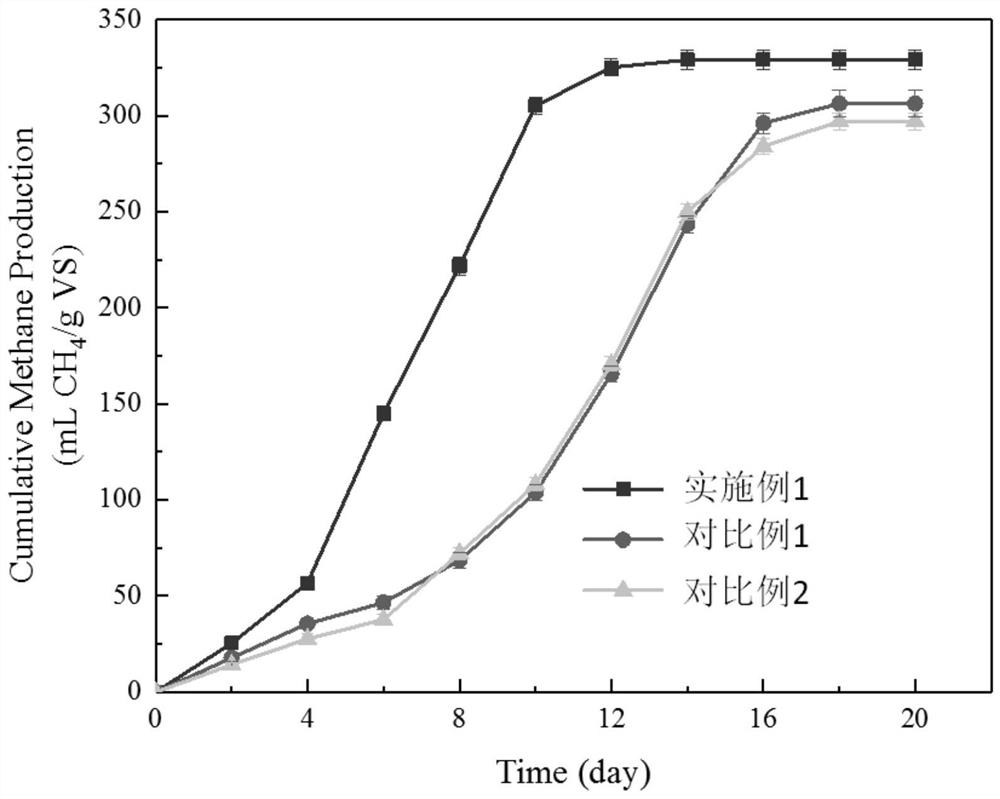

[0032] This example aims to implement a method for enriching efficient microorganisms to enhance anaerobic digestion of organic waste in a batch methane production experiment using municipal sludge as a substrate.

[0033] Using the residual sludge (VS / TS=45.1-70.8%, TS=1.5-5.1%) of the secondary sedimentation tank of the sewage treatment plant as the substrate, the anaerobic digestion sludge (VS / TS=33.2- 48.9%, TS=2.1-6.3%) as the inoculum, and batch anaerobic methanogenesis experiments were carried out in 500 mL serum bottles.

[0034] A magnet-ferric oxide catalyst was then added, wherein the magnet was a spherical ferrite magnet with a diameter of 3 cm, the particle size of ferric oxide was 200 nm, and the mass ratio of ferric oxide to magnet was 1:2. The mass ratio of VS of excess sludge to VS of inoculum was 2:1, and the mass ratio of ferric oxide to TS of excess sludge was 1:1. At the same time, a blank group with only inoculum was set up to eliminate the influence of ...

Embodiment 2

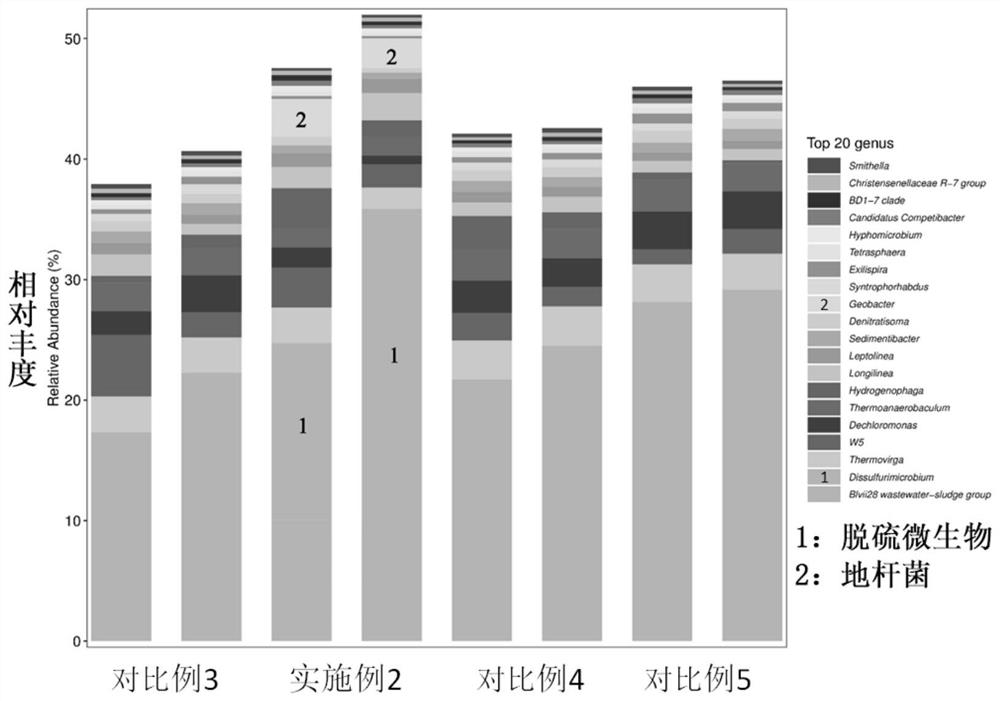

[0046] The purpose of this example is to implement a method for enriching efficient microorganisms and enhancing anaerobic digestion of organic waste in a semi-continuous methanogenic experiment using kitchen waste as the substrate.

[0047] The anaerobic digested sludge (VS / TS=31.6- 48.9%, TS=2.3-5.7%) was used as the inoculum, and a semi-continuous anaerobic methanogenesis experiment was carried out in a reactor with a working volume of 2 L.

[0048] Added the magnet-ferric oxide catalyst again, wherein the magnet is a cylindrical NdFeB magnet with a diameter of 4cm and a height of 1cm, the particle size of the ferric oxide is 100nm, and the mass ratio of the ferric oxide to the magnet is 1:10, adding The mass ratio of Fe3O4 to TS of food waste was 1:3, and the mass ratio of VS of food waste to inoculum was 2:1. At the same time, a blank group with only inoculum was set up to eliminate the influence of inoculum.

[0049] The semi-continuous reactor discharges 200mL and fee...

Embodiment 3

[0058] This example aims to implement a method for enriching highly efficient microorganisms to enhance anaerobic digestion of organic waste in the continuous methane production experiment.

[0059] Using the residual sludge of the secondary settling tank (VS / TS=50.9-68.8%, TS=1.7-4.8%) as the substrate, the anaerobic digestion sludge in the anaerobic digestion reactor (VS / TS=33.1-45.8 %, TS=2.0-5.5%) as the inoculum, and the continuous methane production experiment was carried out in a reactor with a working volume of 4 L.

[0060] Added magnet-ferric oxide catalyst again, wherein magnet is internal diameter 2cm, outer diameter 4cm, the ferrite magnet ring of high 1cm, ferric oxide particle diameter is 150nm, ferric oxide and magnet mass ratio are 1: 1. The mass ratio of the VS of the remaining sludge to the VS of the inoculum is 2:1. At the same time, a blank group with only inoculum was set up to eliminate the influence of inoculum.

[0061] Adopt continuous feeding and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com