Method for promoting formation of anaerobic granular sludge

An anaerobic granular sludge and granular sludge technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of difficult separation and recovery of mature granular sludge, anaerobic granular Slow slime formation, high cultivation costs and other problems, to achieve the effect of improving the tolerance of organic load and toxic substances, improving redox ability, and increasing the granulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

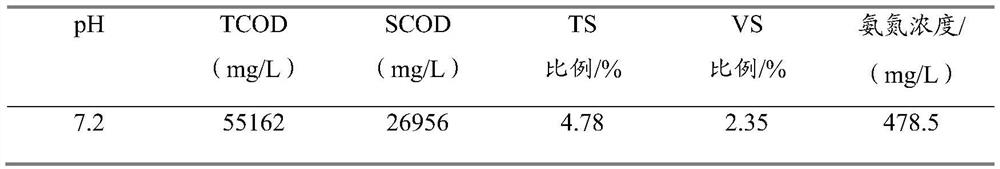

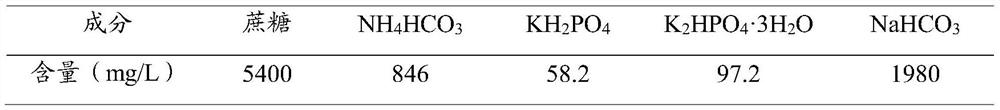

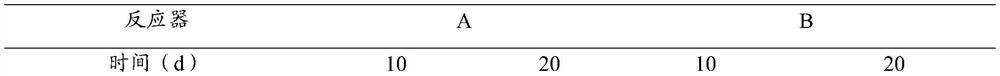

Embodiment 1

[0042] In two UASB reactors A and B with a diameter of 60 cm and a total volume of 7.5 L, 3.5 L of anaerobic sludge from an urban sewage treatment plant was inoculated, the parameters are shown in Table 1, and the influent was synthetic wastewater (Table 2 ), the reaction temperature is controlled at 35-37°C. In the anaerobic reactor A, the feeding diameter is 3-4mm and the density is 1.2g / cm 3 The hollow iron ball, the dosage is 50g / L. Anaerobic reactor type B does not add hollow iron balls, and other parameters are consistent with A. Each anaerobic reactor was inoculated with 2.5L sludge, the initial hydraulic retention time was 12h, and the reflux ratio was controlled to be 0.6 so that the rising velocity of the influent was 0.1m / h. After 10 days, the hydraulic retention time is still 12h, the reflux ratio is increased to 1.2, and the ascending flow rate is increased to 0.2m / h. On the 20th day of the reaction, the operation was suspended, and the granular sludge was reco...

Embodiment 2

[0052] In two diameters of 300cm, with a total volume of 2m 3 In the UASB reactors A and B, the anaerobic sludge from the urban sewage treatment plant was inoculated. The parameters are shown in Table 1. The influent was diluted chicken farm wastewater with high nitrogen and phosphorus content. The specific components As in Table 4. In the anaerobic reactor A, add PCV plastic balls (diameter 1-2mm, density 1.1g / cm2) with magnet ore powder coating on the surface 3 ), the dosage is 40g / L. No plastic pellets are added to anaerobic reactor B, and other parameters are consistent with A. Each anaerobic reactor was inoculated with 0.5m 3 For sludge, the initial hydraulic retention time is 12h. At the initial stage of start-up, the reflux ratio is controlled to be 0.6 so that the rising velocity of the influent water is 0.1m / h. After 10 days, the hydraulic retention time was maintained at 12h, the reflux ratio was increased to 1.2, and the ascending flow rate was increased to 0.2...

Embodiment 3

[0059] In two diameters of 120cm and a total volume of 1.5m 3 In the UASB reactors A and B, the anaerobic sludge from the urban sewage treatment plant was inoculated, and its parameters are shown in Table 1. In the anaerobic reactor A, the feeding diameter is 3-4mm and the density is 1.1-1.2g / cm 3 Hollow stainless steel balls, the dosage is 60g / L. There is no addition in anaerobic reactor B, and other parameters are consistent with A. Each anaerobic reactor was inoculated with 2.5m 3 Sludge, the reaction runs for a total of 42 days, divided into start-up phase (1-7 days) and acclimation phase (8-42 days). In the start-up stage, the influent water is synthetic wastewater (see Table 2), the hydraulic retention time is 24h, and the reflux ratio is controlled to be 0.6 in the initial stage of start-up so that the influent flow rate is 0.1m / h. During the acclimatization stage, the influent was simulated pesticide chemical factory phenazine-containing wastewater (see Table 6), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com