Alkali aluminosilicate glass with high elastic modulus and preparation method thereof

A technology of silicate glass with high elasticity, which is applied in glass manufacturing equipment, glass tempering, glass molding, etc., and can solve problems such as poor elastic modulus of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing the high elastic modulus alkali aluminosilicate glass described in the above technical solution, comprising the following steps:

[0064] a) Quartz sand, alumina, dolomite, magnesia, soda ash and LaCl 3 ·7H 2 O mixed to obtain a mixture;

[0065] b) heating and melting the mixture to obtain molten glass;

[0066] c) After pouring the molten glass into a mold for molding, annealing is performed to obtain glass.

[0067] Regarding step a):

[0068] The quartz sand, alumina, dolomite, magnesia, soda ash and LaCl 3 ·7H 2 O respectively corresponds to SiO in the glass 2 、Al 2 o 3 , CaO, MgO, Na 2 O, La 2 o 3 The constituents, ie the respective oxide constituents, are introduced by starting materials of the form described above. The amount of the above-mentioned raw materials is based on the composition ratio of the corresponding oxides in the target glass, that is, according to the composition of the targ...

Embodiment 1

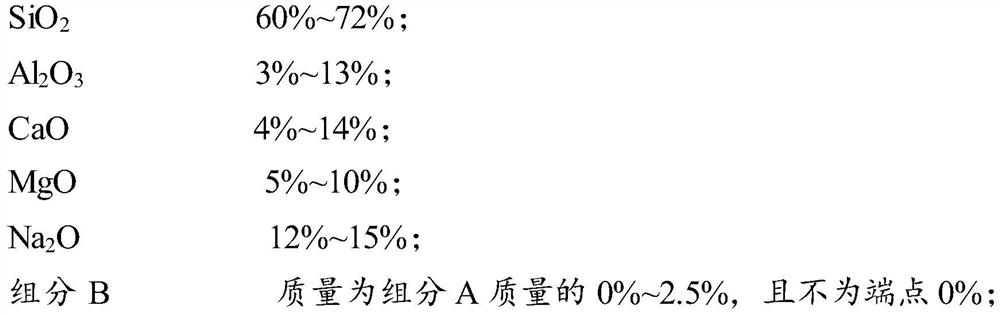

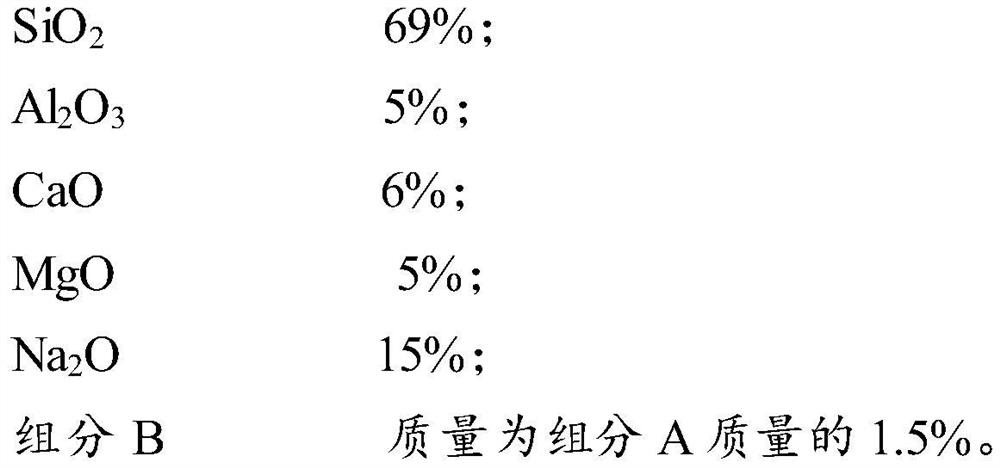

[0078] 1. Glass composition:

[0079] Component A:

[0080]

[0081] 2. Preparation of glass

[0082] S1. Combine quartz sand, alumina, dolomite, magnesia, soda ash and LaCl 3 ·7H 2 O mixed to obtain a mixture;

[0083] Wherein, the feeding ratio of each raw material mentioned above is based on the ratio of each oxide in the glass product.

[0084] S2. Heat and melt the above mixture at 1550° C. for 5 hours to obtain molten glass.

[0085] S4. After pouring the molten glass into a mold for molding, anneal at 580° C. for 3 hours, and cool to room temperature to obtain glass.

[0086] 3. Performance test

[0087] The following performance tests were carried out on the obtained glass samples:

[0088] (1) After cutting the obtained glass, measure the modulus of elasticity, see Table 1 for the test results.

[0089] (2) After the obtained glass is chemically strengthened and further processed, the strengthening performance is tested:

[0090] Put cut glass into KNO 3 ...

Embodiment 2

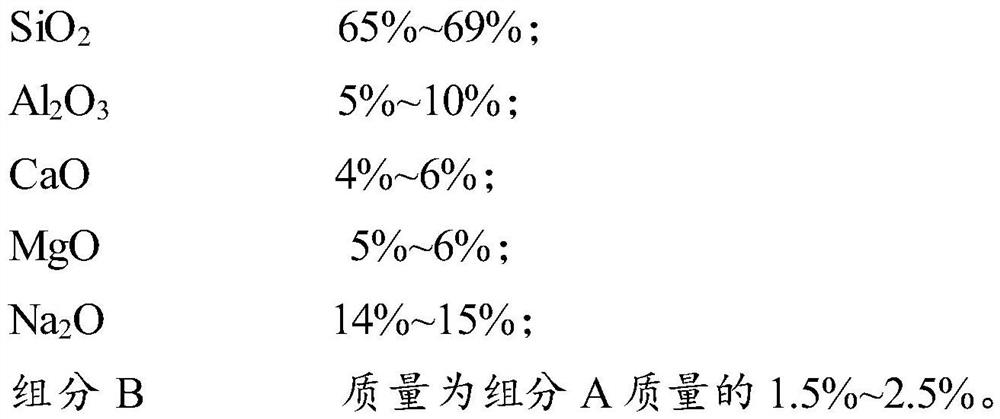

[0093] 1. Glass composition:

[0094] Component A:

[0095]

[0096] 2. Preparation of glass

[0097] S1. Combine quartz sand, alumina, dolomite, magnesia, soda ash and LaCl 3 ·7H 2 O mixed to obtain a mixture;

[0098] Wherein, the feeding ratio of each raw material mentioned above is based on the ratio of each oxide in the glass product.

[0099] S2. Heat and melt the above mixture at 1550° C. for 5 hours to obtain molten glass.

[0100] S4. After pouring the molten glass into a mold for molding, anneal at 580° C. for 3 hours, and cool to room temperature to obtain glass.

[0101] 3. Performance test

[0102] Each performance test was carried out according to the test method of Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

| Depth of stress layer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com