Reaction system and reaction method for preparing divinyl benzene by dehydrogenation of diethylbenzene

A technology for producing divinylbenzene by dehydrogenation of diethylbenzene and a reaction system, which is applied to chemical instruments and methods, hydrocarbons, hydrocarbons, etc. Reaction pressure drop and other problems, to achieve the effect of improving energy utilization efficiency, low bed resistance, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

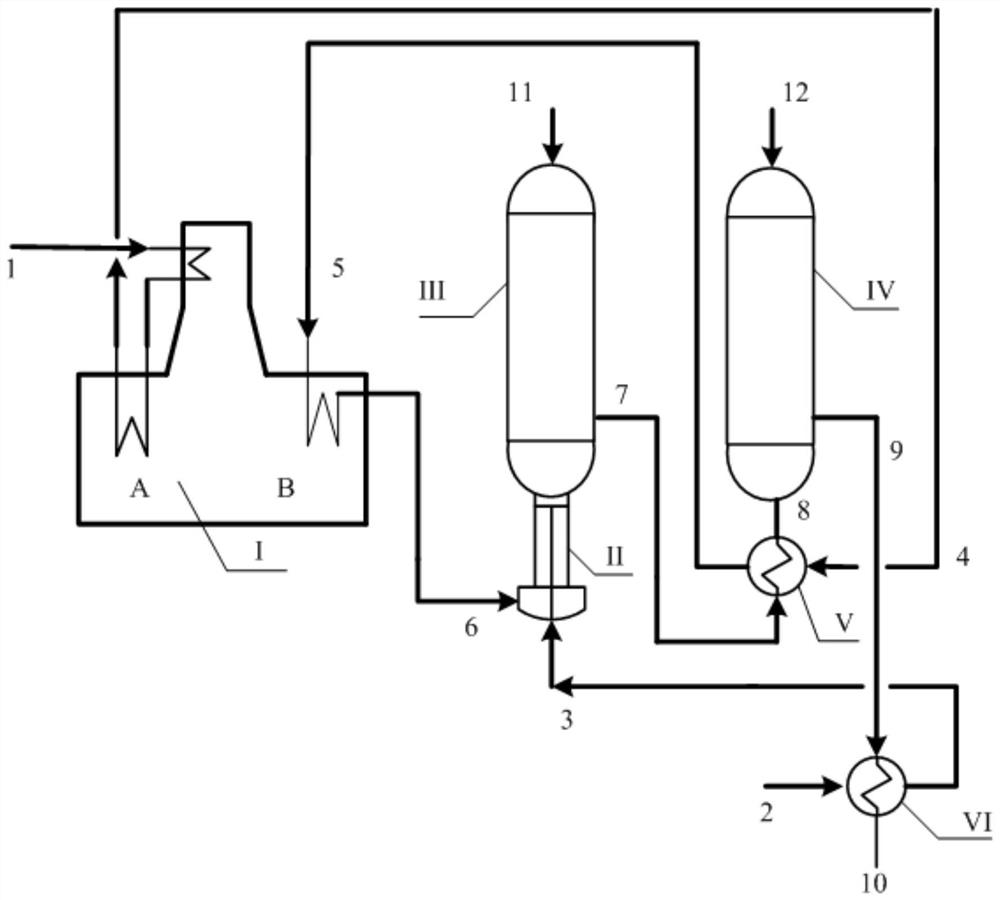

[0044] Such as figure 1 Shown, a kind of diethylbenzene dehydrogenation reaction system (8000 hours of operating hours) of divinylbenzene.

[0045] include:

[0046] The first dehydrogenation reactor, the second dehydrogenation reactor, the heating furnace, the second dehydrogenation reactor feed heat exchanger and the second dehydrogenation reactor discharge heat exchanger;

[0047] A raw material mixer is arranged at the bottom of the first dehydrogenation reactor; the raw material mixer is connected with the first dehydrogenation reactor;

[0048] The diethylbenzene feed line is connected to the discharge heat exchanger of the second dehydrogenation reactor and then connected to the raw material mixer; the steam feed line is connected to the heating furnace, and there are two outlet pipelines of the heating furnace, one connected to the raw material mixer and the other Return to the heating furnace after the branch is connected to the feed heat exchanger of the second deh...

Embodiment 2

[0061] A certain 10,000 tons / year divinylbenzene plant (8000 hours of annual operating hours), the same as Example 1, the only difference is that the distance between the outlet line of the first dehydrogenation reactor and the bottom of the dehydrogenation reactor accounts for the total amount of the dehydrogenation reactor. 15% of the height; the distance between the outlet line of the second dehydrogenation reactor and the bottom of the dehydrogenation reactor accounts for 15% of the total height of the dehydrogenation reactor;

[0062] Reaction method is with embodiment 1, difference is:

[0063] The mass ratio of water to diethylbenzene is 1.56, the pressure of the first dehydrogenation reactor is 59Kpa, and the feed temperature of the first dehydrogenation reactor after mixing is 630°C;

[0064] The pressure of the second dehydrogenation reactor is 50Kpa, and the feed temperature after mixing in the second dehydrogenation reactor is 635° C., and the content of divinylben...

Embodiment 3

[0067] A certain 10,000 tons / year divinylbenzene plant (8000 hours of annual operating hours), the same as in Example 1; the difference is only that the distance between the outlet line of the first dehydrogenation reactor and the bottom of the dehydrogenation reactor accounts for the total amount of the dehydrogenation reactor. 25% of the height; the distance between the outlet line of the second dehydrogenation reactor and the bottom of the dehydrogenation reactor accounts for 25% of the total height of the dehydrogenation reactor;

[0068] Method is with embodiment 1;

[0069] The difference is that:

[0070] The mass ratio of water to diethylbenzene is 1.34, the pressure of the first dehydrogenation reactor is 60Kpa, and the feed temperature of the first dehydrogenation reactor after mixing is 620°C;

[0071] The pressure of the second dehydrogenation reactor is 52Kpa, and the feed temperature after mixing in the second dehydrogenation reactor is 625° C., and the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com