Monocrystalline silicon doping method and monocrystalline silicon manufacturing method

A single crystal silicon and dopant technology, applied in the field of solar photovoltaics, can solve the problem of uneven distribution of resistivity at the head and tail of single crystal silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

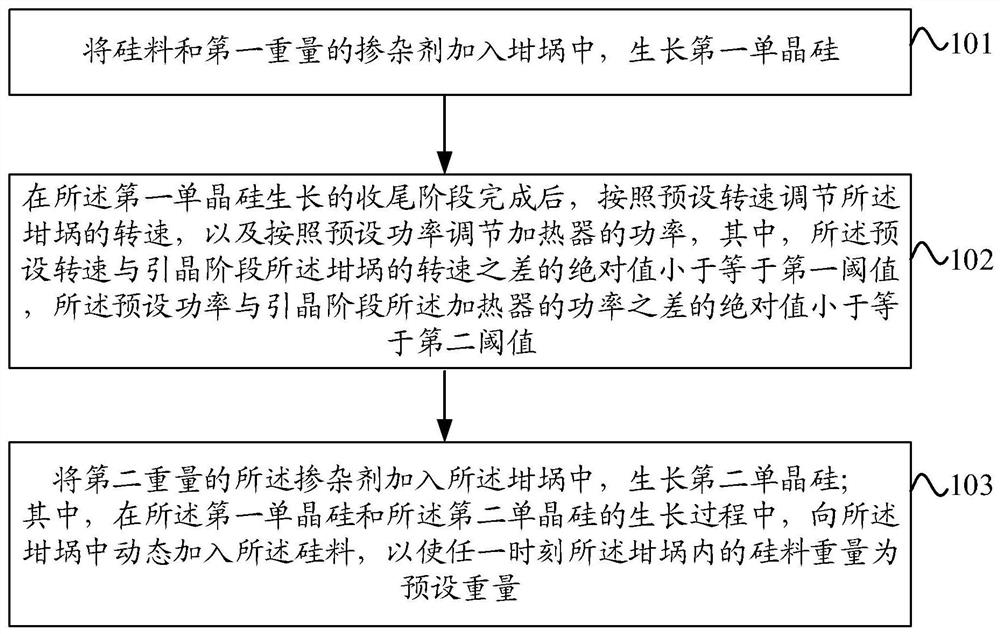

[0053] refer to figure 1 , which shows a flow chart of a single crystal silicon doping method according to an embodiment of the present invention, which may specifically include the following steps:

[0054] Step 101 , adding silicon material and a first weight of dopant into a crucible to grow a first single crystal silicon.

[0055]In the embodiment of the present invention, the silicon material may be raw polysilicon material, etc., which is not limited in the embodiment of the present invention. In order to ensure the resistivity of the single crystal silicon, the single crystal silicon needs to be doped, and the type of dopant can be determined according to the conductivity type of the target single crystal silicon. For example, when the conduction type of the target monocrystalline silicon is P-type, a trace amount of group IIIA elements, such as gallium, boron, aluminum, etc., can be doped; VA group elements, such as phosphorus, antimony, arsenic, etc. It can be unde...

Embodiment 2

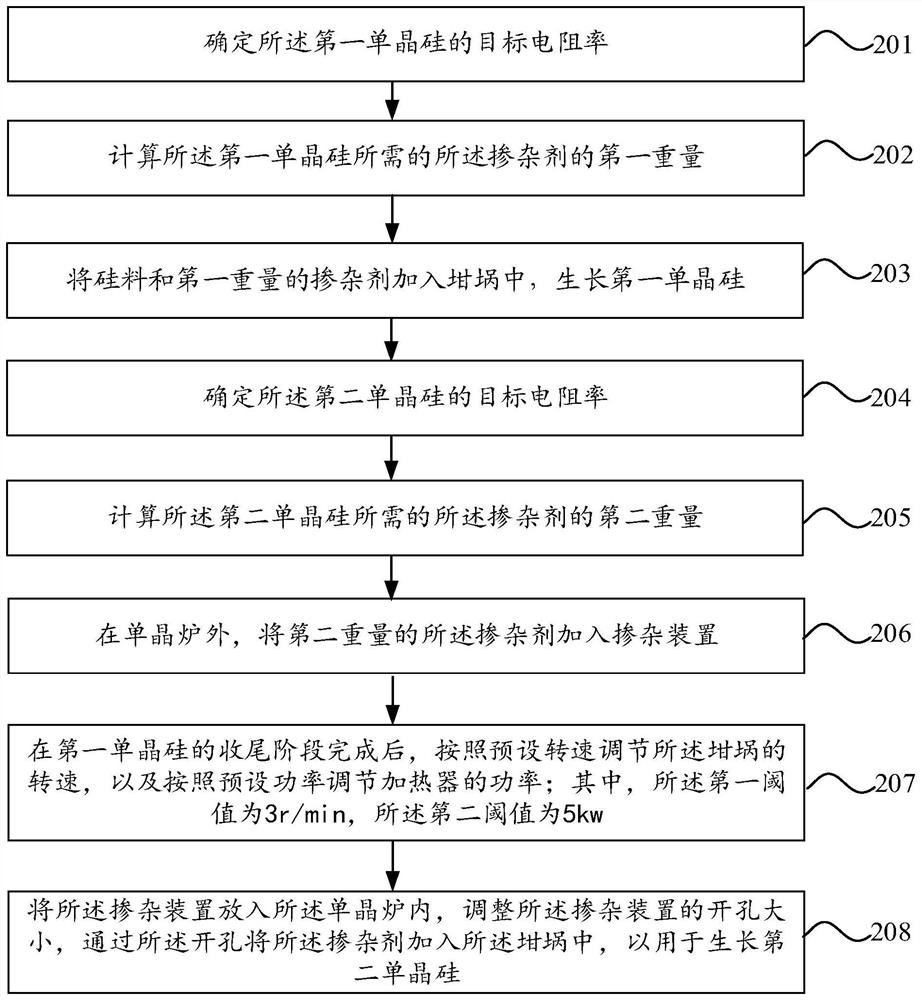

[0065] refer to image 3 , which shows a flow chart of a single crystal silicon doping method according to Embodiment 2 of the present invention, which may specifically include the following steps:

[0066] Step 201, determining the target resistivity of the first single crystal silicon.

[0067] In the embodiment of the present invention, determining the target resistivity of the first single crystal silicon includes determining the conductivity type and the value of the target resistivity of the first single crystal silicon, and the conductivity type and the target resistivity value of the single crystal silicon will directly affect the value of the single crystal silicon. The conductivity of silicon, so when monocrystalline silicon is used to make solar cells, it will affect the performance of solar cells. Its conductivity type can be P-type or N-type. The majority carriers in P-type single crystal silicon are mainly holes in single crystal silicon. The more impurities of ...

Embodiment 3

[0086] refer to Figure 4 , shows a flow chart of a single crystal silicon doping method according to Embodiment 3 of the present invention, which may specifically include the following steps:

[0087] Step 301 , adding silicon material and a first weight of dopant into a crucible to grow a first single crystal silicon.

[0088] Step 302, after the finishing stage of the growth of the first single crystal silicon is completed, the rotation speed of the crucible is adjusted according to the preset rotation speed, and the power of the heater is adjusted according to the preset power;

[0089] Step 303, adding a second weight of the dopant into the crucible to grow a second single crystal silicon.

[0090] In the embodiment of the present invention, step 301 may refer to the above-mentioned step 101, step 302 may refer to the above-mentioned step 102, and step 303 may refer to the above-mentioned step 103. To avoid repetition, details are not repeated here.

[0091] Step 304, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com