Carbon fiber composite material processing equipment

A composite material, processing equipment technology, used in woven fabrics, textiles, and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

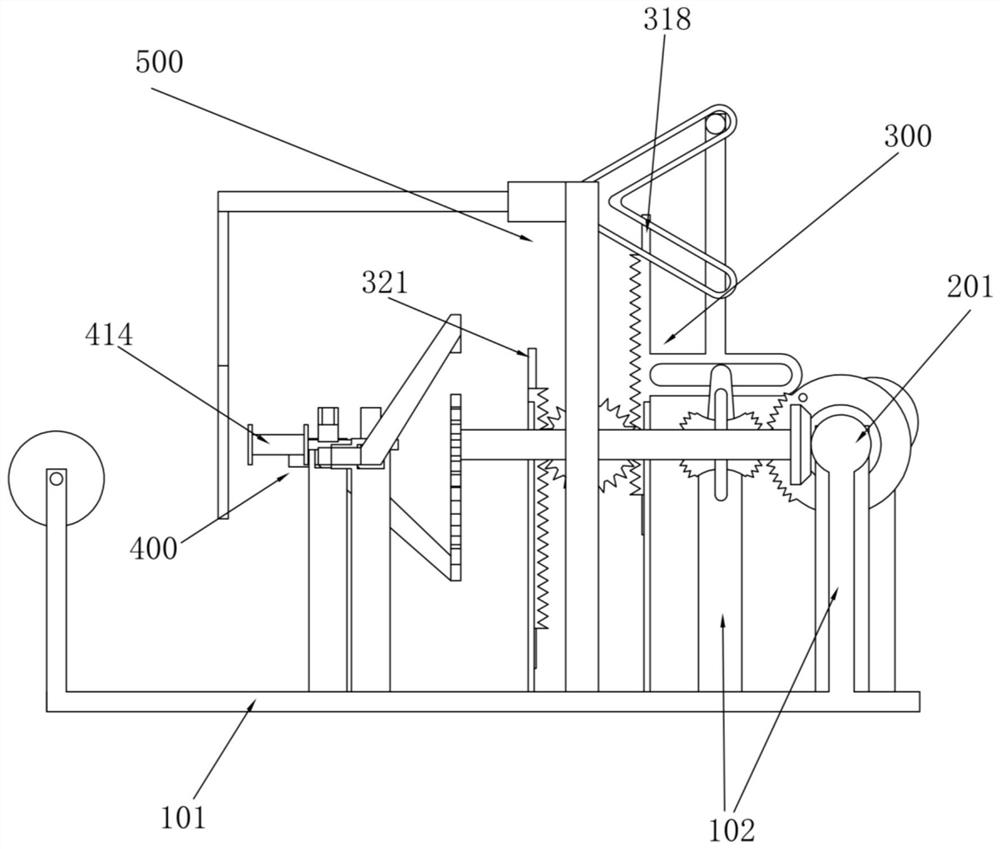

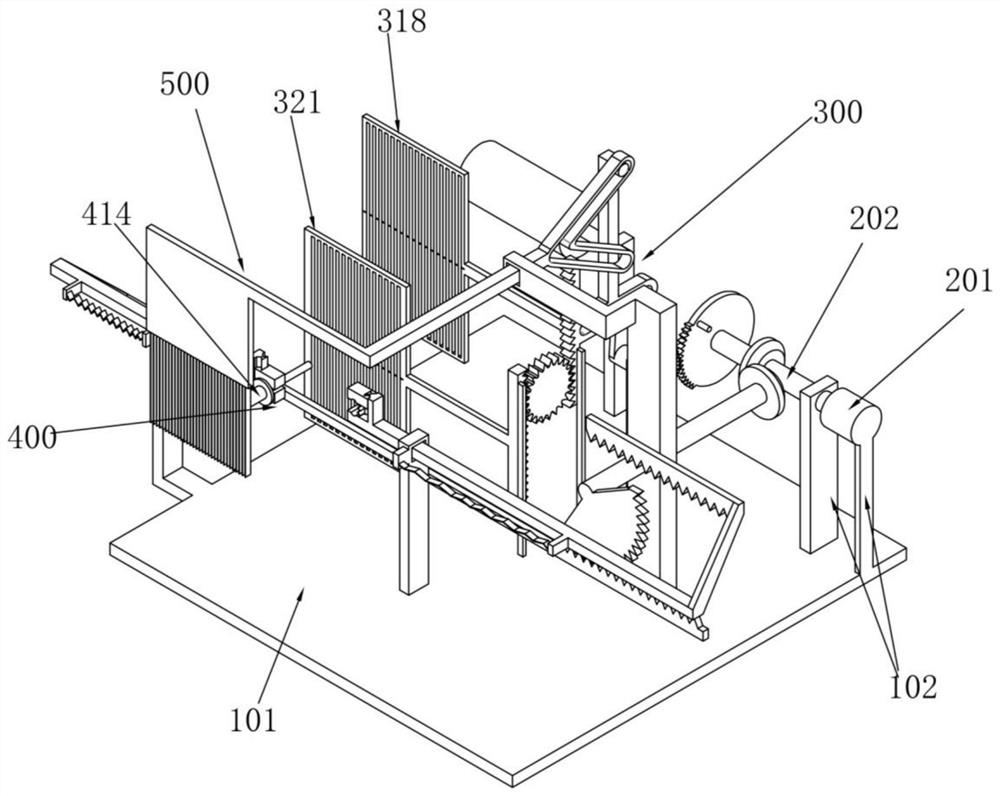

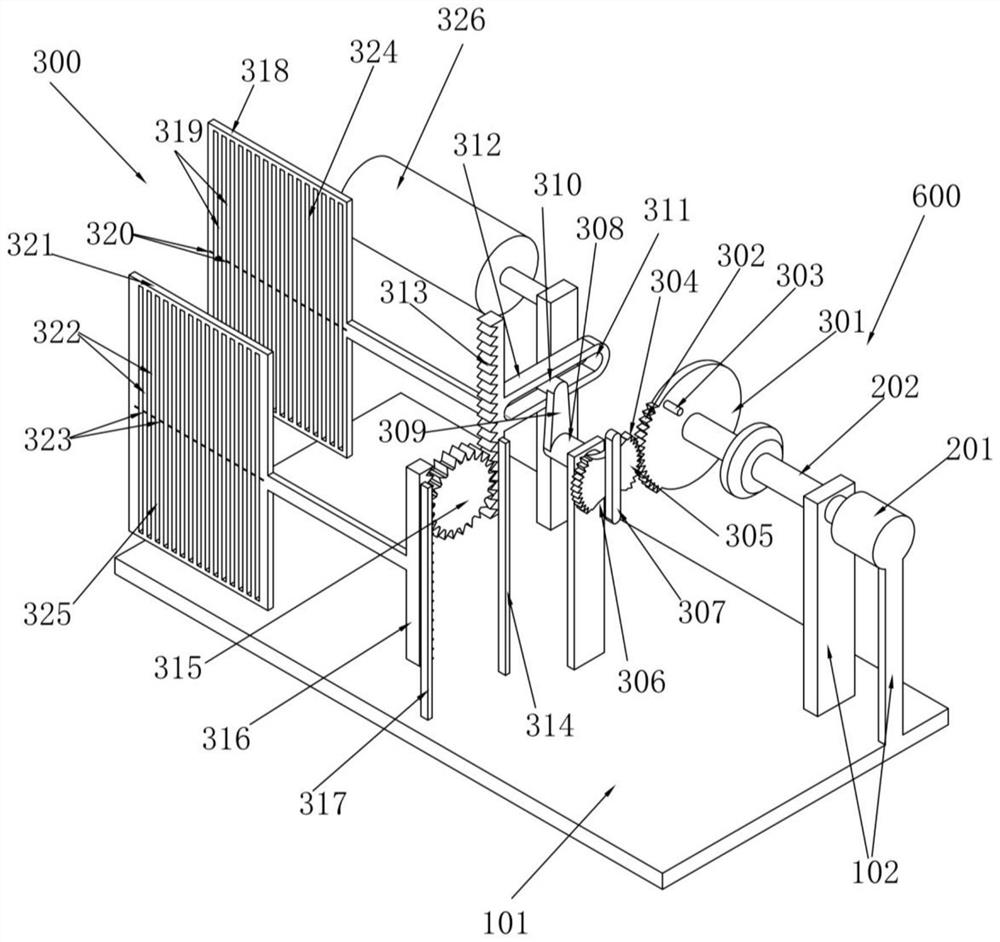

[0037] Such as figure 1 , 2 Shown, a kind of carbon fiber composite material processing equipment of the present invention comprises

[0038] Base plate 101, on which bracket 102 is installed;

[0039] The swing mechanism 300 is installed on the bracket 102 and driven by the motor 201 to realize the staggered movement of the first baffle 318 and the second baffle 321 , thereby realizing the staggered transformation of the positions of a plurality of prepreg narrow strips.

[0040]The motor 201 of the present invention drives the swing mechanism 300 to realize the up and down staggered movement of a plurality of prepreg narrow strips. By swinging up and down once, the operator penetrates a horizontal prepreg narrow strip, and finally realizes the staggered weaving of prepreg narrow strips, which can overcome the defects of this kind of composite material to the greatest extent and make it meet the needs of more working environments.

[0041] Wherein, the bottom plate 101 can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com