Double-layer curtain wall system with outer-layer curtain wall made of UHPC material

A curtain wall and outer layer technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult maintenance and repair of curtain wall panels, affecting the internal lighting of buildings, low work efficiency, etc., to solve lighting problems, simple construction, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

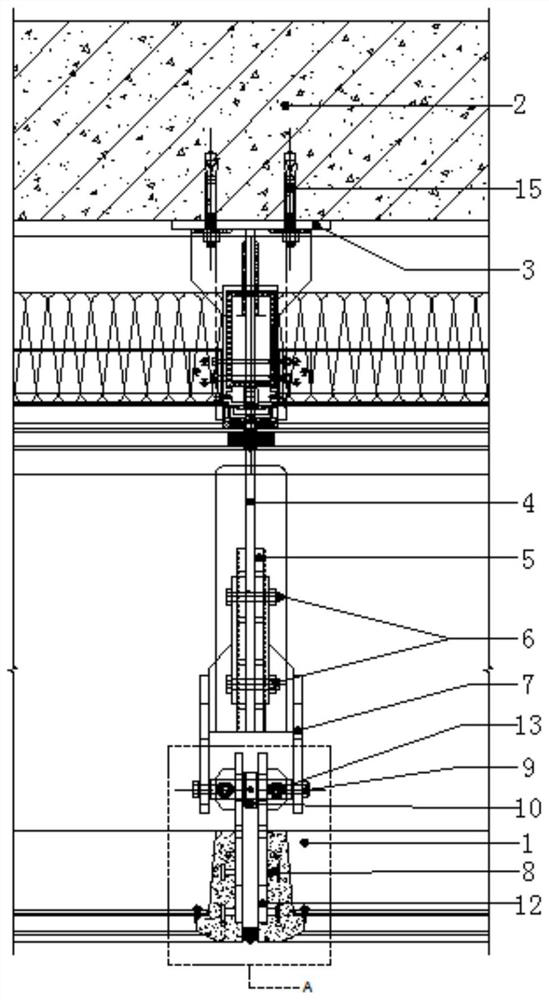

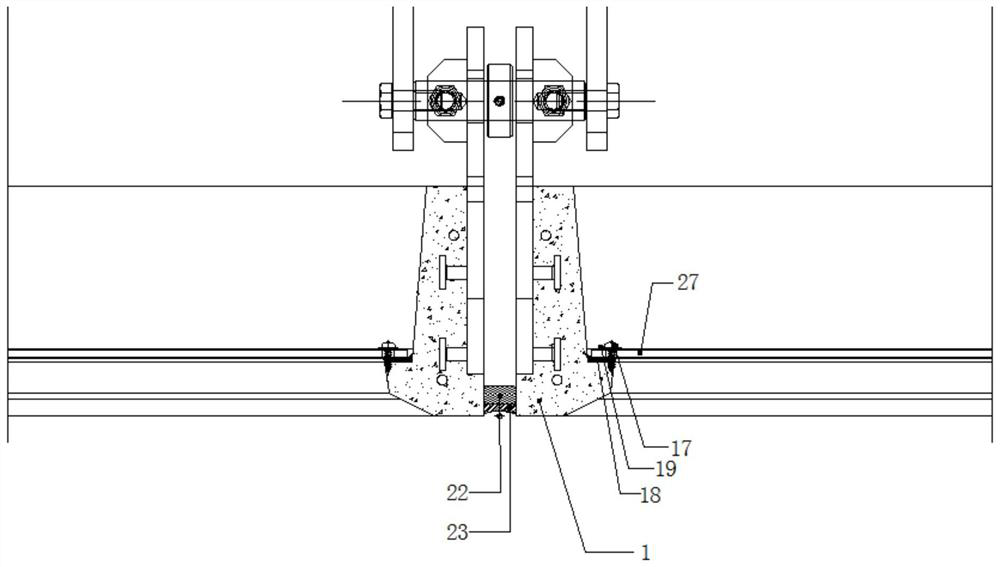

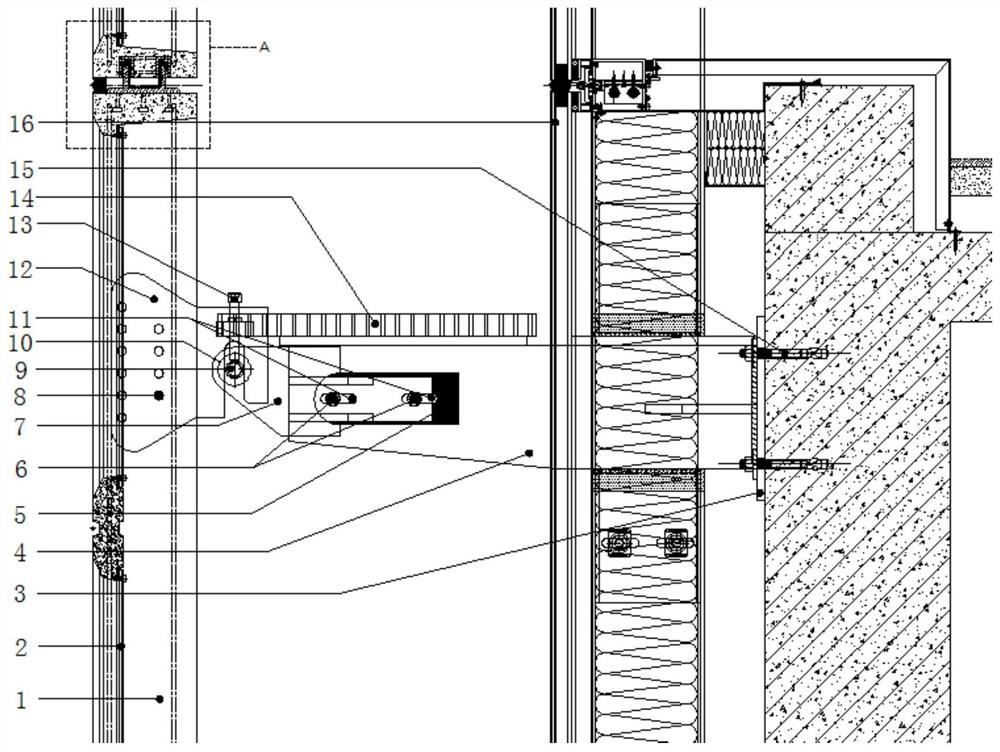

[0048] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0049] see Figure 1 to Figure 9 As shown, the present invention is a double-layer curtain wall system in which the outer curtain wall is made of UHPC material, including an inner curtain wall panel 16 fixedly connected to the side near the facade wall 2, and the facade wall 2 is provided with a pre-embedded panel 3, The embedded panel 3 is fixedly connected with a "T"-shaped steel bracket 4 facing outward. The steel bracket 4 extends to the outside of the inner curtain wall panel 16. The steel bracket 4 is fixed and connected symmetrically on both sides of the end away from the facade wall 2. There are adjustable pendants 7, and the adjustable pendants 7 on both sides are fixedly connected with hanging point bolts 9 arranged horizontally between the ends far away from the steel bracket 4, and the outer curtain wall panels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com